Design for deconstruction, BRE modular show house

This article was written by Kathryn Adams, Principal Consultant at BRE. It originally appeared in --BRE Buzz on 16 Dec 2015, Design for Deconstruction: Case Study : Modular Show House Construction.

[edit] Introduction

This case study uses a new methodology to assess the deconstruction potential of new build properties. The case study and methodology were funded by the BRE Trust to raise awareness amongst architects, designers and contractors of the potential of Design for Deconstruction (DfD) to create more sustainable buildings and lead to better deconstruction outcomes.

This modular show house was prefabricated and brought to site for erection in four virtually complete, pre-fitted pods. The pods were assembled in Northern Ireland in factory conditions. It is designed to be highly resource efficient in terms of energy, water and waste prevention, both in construction and occupation. Operationally, it will require minimum energy input and maximises the use of renewable energy.

It is intended that the show house sets a standard which can be replicated as a model for a low cost, lean construction house type, prefabricated off-site and therefore encourage resource efficient principles in housing design. It intended that the units will be relocated, and as such, the modules have been put together with the principles of deconstruction in mind, focusing on demounting and the use of a steel frame throughout.

[edit] Building description

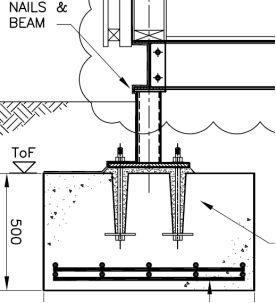

The modular design and construction process allows for a very short on-site construction period, with minimal construction waste. The two ground level pods have steel beams built into their floor cassettes which are then spot welded to a steel grillage and stub columns, which are mechanically connected to the reinforced concrete pad foundations.

The upper pods simply sit on the lower units and are held in place by their dead weight. There are no independent connections, making disassembly much simpler. The services were connected onsite along with the remaining internal fixtures and fittings installed.

The key elements used for the show house are.

- Frame: Partial steel frame to strengthen the oversized ground level pods and assist with deconstruction at a later date.

- Foundation: Concrete pad foundations.

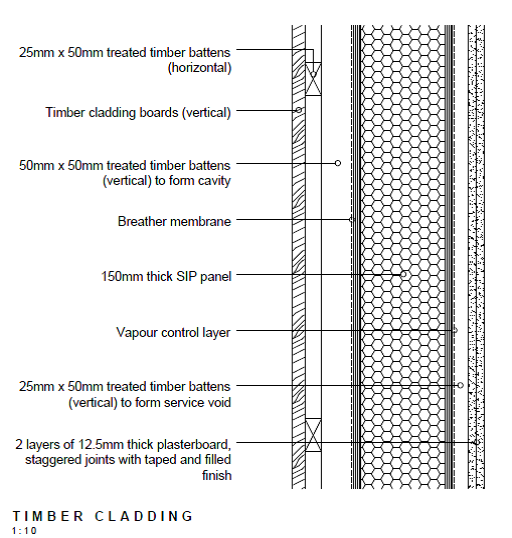

- External walls: Structurally insulated panels (SIPS).

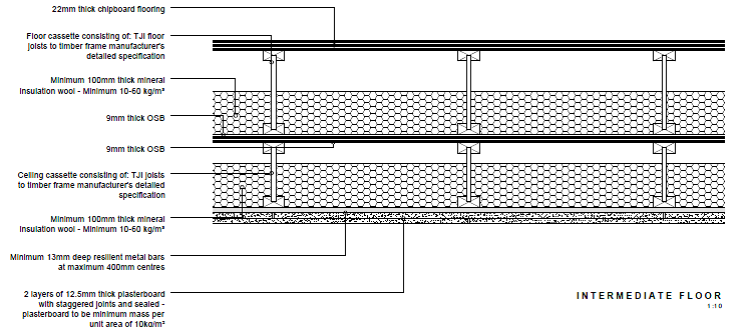

- Ground floor, upper floor and ceiling: Pre-fabricated, insulated cassettes.

- Cladding: Reconstituted stone cladding blocks, lime render and locally sourced larch cladding.

- Floor finishes: Carpet tiles, ceramic tiles, hardwood tongue and groove strip flooring.

- Windows and doors: Engineered timber framed, triple glazed, low-e glass, veneered fire doors.

- Sanitary ware: ceramic dual flush WC; sink with low flow taps; wet room with ceramic tiling, steel bath.

- Services: All air mechanical heat recovery ventilation system, air source heat pump, photovoltaic panels and a wood pellet stove.

- Fixtures and Fittings: Fitted chipboard kitchen units including cabinets, doors, décor panels, cornice, pelmet and plinths. Kitchen worktops made from recycled coffee cups with stainless steel handles and built in wardrobes with painted ply faced wardrobe doors.

- Steel staircase and balustrading.

[edit] DfD assessment

An assessment was undertaken on the available design drawings to determine the potential for deconstruction based on the outline methodology. This involved looking at the following issues/criteria:

- Project documentation: Appropriate project documentation is very important for DfD. When the building has reached its end of its life, sufficient information should be available for the demolition contractor to be able to deconstruct the building, identify the components and materials that have been used and their potential for reuse and recycling.

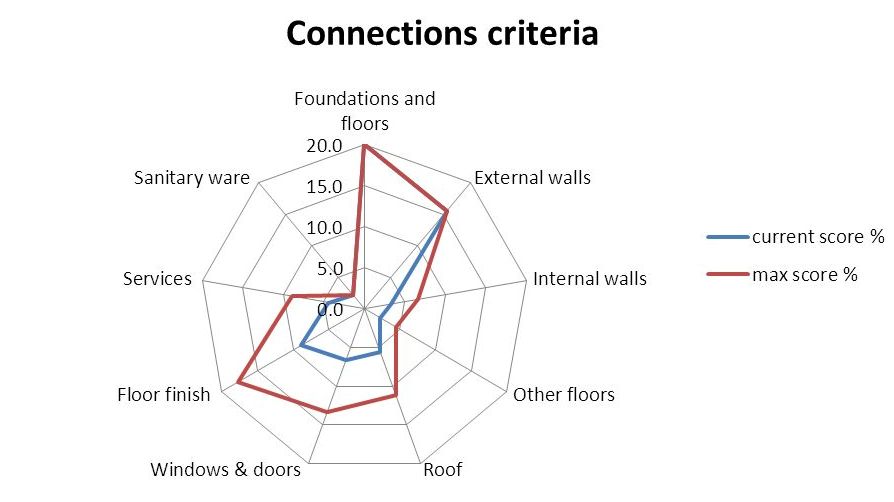

- Connections: The connections between the elements are a key factor to enable effective deconstruction including their ease of access and the type used. Retrievable mechanical fixings are preferable.

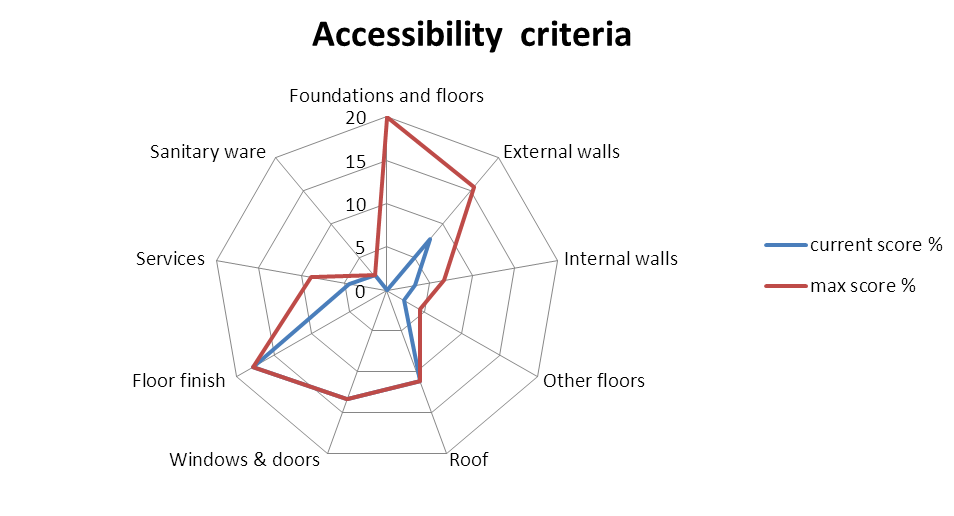

- Accessibility: The main issue is to consider is that when components and elements are to be removed, they cause minimal damage to the surrounding components and if they are to be reused, they remain in good condition. Areas where accessibility is probably more important include the services, windows and doors, roof and the floor finishes. These components have a shorter life than others and as such are likely to be replaced a number of times.

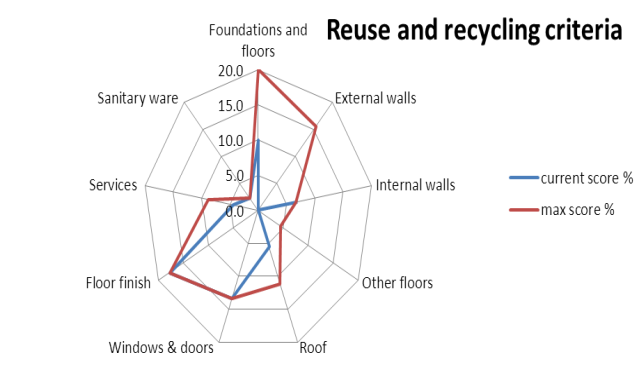

- Reuse and recycling potential: Reuse of elements and components is preferable to recycling according to the waste hierarchy and therefore scores higher. Through reuse and recycling, fewer resources are used, saving energy and raw materials.

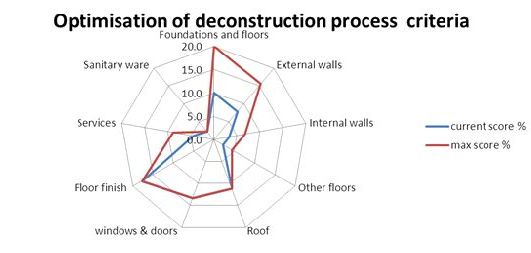

- Optimisation of the deconstruction process: This considers the potential impact on the workforce in terms of the ability to reach components and remove them safely and the requirements for specialised equipment, which would incur cost.

- It should be noted that the show house was designed without the benefit of BIM or any allowance for a DfD methodology.

[edit] Project documentation

The procurement process for the show house was non-standard, as the project was awarded through a competition, instead of a traditional tender approach. Within this competition process, DfD was included as an overarching objective.

[edit] Connections

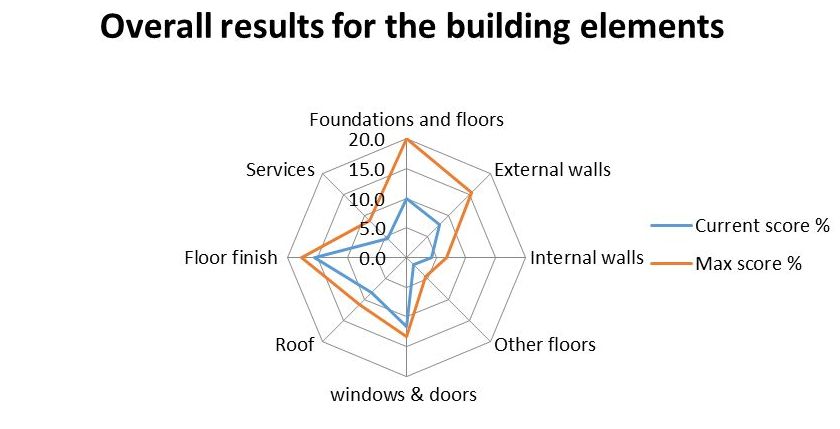

Overall score achieved – 69%. The radar graph shows the maximum weighted score available for each element in relation to the connections criteria and the current (actual) score. So for example, for the roof a maximum score of 12 was possible; however a score of 5 was awarded as there were a number of connections which would aid deconstruction.

[edit] Modular units (external walls, internal walls and floors)

The 4 pods are constructed using SIP panels. Individual pods are delivered to site as whole units, with the pods stiffened with a partial steel frame. The ground beam grillage sits below the floor cassettes and is welded to steel stub columns as shown by Figure 1. The upper pods are not connected to the two base pods – these therefore score well for disassembly. Figure 2 shows the external wall of the pod with the timber cladding. Figure 3 shows the floor cassette. Both the mid-floor (Figure 4) and the ceiling construction are also made of insulated modular floor cassettes mechanically secured to the external SIP wall panels which will aid deconstruction.

[edit] Cladding

A number of cladding types have been used. Larch timber cladding boards are mechanically fixed to treated timber battens (details shown in Figure 5); these could be removed relatively easily. Lime render is applied to external wallboard as a secondary external material and stone cladding blocks have been fixed on to the SIP walls employing a proprietary cementitious mortar – this will present deconstruction issues in the future when it comes to removing the cladding blocks.

[edit] Roof

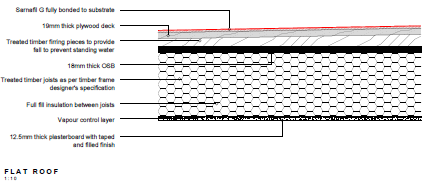

The mono pitch roof was partially site constructed from prefabricated trusses held in position with galvanised tie straps, using mechanical fixings. The single ply roofing is mechanically fixed using a manufacturer’s staple and fastening system to the substrate and then all the seams are hot welded. The weatherproof membrane system comprises a vapour control barrier, loose laid on to a 19mm thick OSP (oriented strand board) plywood deck which should be easily disassembled (See Figure 6).

[edit] Floor finishes

The floor finishes include carpet tiles in circulation and bedroom areas, ceramic floor tiles in kitchen and bathrooms, tongue and grooved strip hardwood flooring in the living area. The carpet tiles are laid employing semi-tack adhesives; these could be lifted up for reuse as could the hardwood flooring which is laid employing edge restraint and tacked through the joints.

[edit] Accessibility

Score Achieved: 62%

[edit] The modular units

In terms of deconstruction the ground level pods have been constructed as semi-permanent units, with limited accessibility to be able to remove them from the ground level foundation steel grillage, as it has also been sprayed with temporary foam insulation, making access to the connections difficult.

[edit] Services

The building has a Mechanical Ventilation and Heat Recovery (MVHR) system. The ductwork for the MVHR is integrated within the floor cassettes. Similarly, all the plumbing is concealed within the floor cassettes, with few surfaced mounted ducts. A limited number of plumbing runs are surface mounted. Should leaks occur there could be access difficulties to ductwork and pipework, necessitating the removal of finishes. The electrical towel rail in the bathroom and the night storage heaters are all accessible as is the hot water cylinder and the woodchip stove. The floor finishes, sanitary ware and windows and doors are fully accessible.

[edit] Reuse and recycling potential

Score Achieved: 60%

Key points for consideration:

- The modular units are designed for demounting and reuse elsewhere; assisted by the use of a steel frame. Some of the cladding may be affected by demounting.

- The pad foundation could be reused in-situ; failing that the concrete and steel could be recycled.

- The cassettes could be reused as cassettes elsewhere, if they are undamaged when removed; though this is unlikely.

- The recycling potential of the cassette panels is limited. It would be difficult with normal equipment and time consuming to separate constituent parts of the cassettes including the PUR (polyurethane ) insulation and vapour barrier from the OSB. These materials are not commonly recycled; the timber joists could be recycled.

- A wholly recycled decking plank has been used on the balcony; which could be fully reused elsewhere.

- The stone cladding could potentially be recycled as aggregate; whilst the larch cladding could be fully reused.

- A small amount of timber from the stud walls may be reusable if it is not too contaminated with plasterboard. The plasterboard could be recycled if not contaminated. There is a small market for ground gypsum as soil nutrition or alternatively it could go back into plasterboard manufacture. The timber truss roof is easily demountable and there is potential for its reuse elsewhere.

- The sanitary ware as a whole, together with the kitchen fittings are reusable, dependent upon their condition.

- The wooden doors and windows could all be reused as could the carpet tiles and hardwood strip flooring which came from a recycled source originally.

- There is potential to reuse the woodchip boiler, storage heaters, electrical towel rail, and the duct work where accessible.

[edit] Optimisation of deconstruction

Score achieved: 72%

The building is designed to be demountable to allow the pods to be separated from each other and re-erected elsewhere. The key consideration for demounting the pods is the need for specialised equipment for lifting and moving the pods.

Key considerations for deconstruction of the pods:

- The SIPs will need special tools for disassembly for handling large panels. Other equipment will be needed for the removal of insulation, nails and screws. Similarly, it could be manually harder to separate the metal bars from the OSB and remove screws and nails from the panel.

- Manual deconstruction of the pods and cassettes on site may not be cost-effective, due to the labour cost, value of the recovered material and time involved in deconstruction. The scrap value for the metal may be too small to make the specialist shredding costs of SIP panels and transport cost to specialist facilities to recycle them worthwhile.

[edit] Fixtures and fittings

The kitchen units are built in and are made of chipboard with a minimum of 70% recycled content and stainless steel handles. Recycling is possible, but the more likely route is to become a fuel source. The worktops are manufactured from recycled plastic coffee cups. All the wardrobe doors are ply faced painted and these could be successfully reused. The main staircase is constructed from second hand steel sections, with reclaimed steel balustrades. Both of these elements could be unbolted and reused.

[edit] Summary

The show house scored 66% overall for its DfD potential.

The deconstruction process and connections criterion scored highest and accessibility the lowest. The show house scored high in terms of the potential reuse of the pods as complete units. However it scored less well, if the pods were to be disassembled and the materials and components reused. Elements which had greater potential for DfD are the windows and doors, roof, floor finishes and sanitary ware. They are accessible and have a good reuse/recycling potential. Access is an issue for the ductwork which is mostly encased within the cassettes. The pods which are designed to be disconnected from each other and reused elsewhere, could present issues for deconstruction due to the spray foam covering the spot welding connections to the ground level steel grillage. The following issues are summarised:

- It is questionable whether the bottom pods required spot welding to the steel grillage; as with the top pods their deadweight could have been used to hold them in place, with no connections they would be easier to remove.

- For the cladding, back to back stainless steel render stops should have been used; this would ensure that the lime render would remain intact when removing the top pods. Additionally the use of a rainscreen would enable the easier removal of the stone block cladding (currently fixed with mortar).

- Though the SIPs panels may present recycling issues separating their constituent parts, their speed of erection can be up to 4-5 times faster than other construction types and this needs to be considered within the context of a project and its whole life value.

- Embedding services within the panels could present access issues. If skirting trunking was used with separators for water and electrics this would be likely to aid access and deconstruction.

- The ceramic flooring on the ground floor spans over the pod joints and as such will be damaged, although minimally when the pod is removed. Consideration could have been given to laying this in relation to the pod joints.

- The windows, which are tripled glazed and are low-e glass, are not standard sizes and as such this could limit their reuse potential.

[Figure 1: The detailing for the fixing of the pods to the foundations]

[Figure 2 The external wall of the pod and timber cladding]

[Figure 3 The floor cassette used]

[Figure 4 Mid-floor construction details]

[Figure 5 Timber cladding details]

[Figure 6 Roof fixing details]

[edit] Related articles on Designing Buildings Wiki

- Adapting 1965-1980 semi-detached dwellings in the UK to reduce summer overheating and the effect of the 2010 Building Regulations.

- Airtightness of energy efficient buildings.

- Anatomy of low carbon retrofits: evidence from owner-occupied superhomes.

- BRE articles on Designing Buildings Wiki.

- BRE National Solar Centre.

- BRE Üserhuus.

- Building Research Establishment BRE.

- Deconstruction.

- Design for deconstruction.

- Design for deconstruction – helping construction unlock the benefits of the circular economy.

- Design for deconstruction, office building.

- Design for deconstruction, ski slope.

- Pre-demolition and pre-refurbishment audits.

- Qualitative research and the built environment.

- Structure relocation.

- The Hive.

Featured articles and news

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this.