Rainscreen

The term 'cladding' refers to components that are attached to the primary structure of a building to form non-structural, external surfaces. This is as opposed to buildings in which the external surfaces are formed by structural elements, such as masonry walls, or applied surfaces such as render.

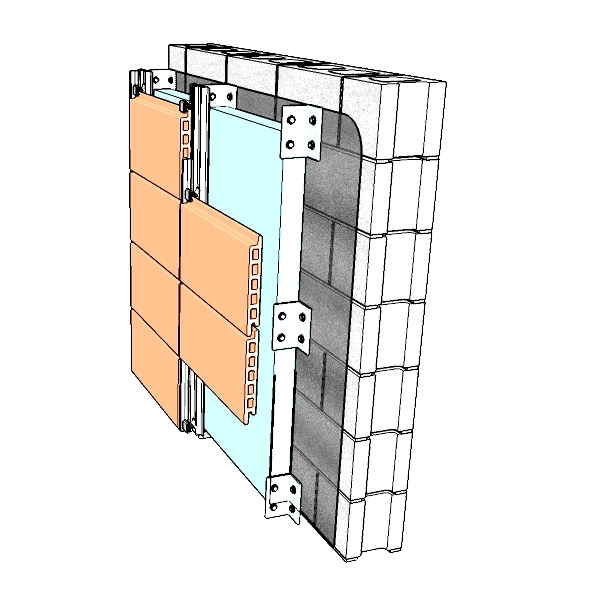

A rainscreen (sometimes referred to as a ‘drained and ventilated’ or ‘pressure-equalised’ façade) is part of a double-wall construction that can be used to form the exterior walls of buildings.

Rainscreen cladding systems were first investigated in the 1940s. They were first used in practice in the 1950s and became more commonplace in the 1960s.

The Centre for Window and Cladding Technology (CWCT) defines a rainscreen cladding system as '...a wall comprising an outer skin of panels and an airtight insulated backing wall separated by a ventilated cavity. Some water may penetrate into the cavity but the rainscreen is intended to provide protection from direct rain'.

Typically rainscreens are formed of relatively thin, pre-fabricated panels. The rainscreen itself simply prevents significant amounts of water from penetrating into the wall construction. Thermal insulation, airtightness and structural stability are provided by the second, inner part of the wall construction.

There are two basic types of rainscreen:

- Drained and ventilated rainscreen cladding systems allow any penetrating moisture to drain or evaporate and vent to the outside. In this case it is necessary to detail the façade so that any penetrating water cannot cross the gap between the rainscreen and the internal wall construction.

- Pressure-equalised (PE) rainscreen cladding systems allow the movement of air between the inside and outside of the rainscreen. This equalises the pressure across the rainscreen so that water is not driven, or sucked through the joints.

The difference between the two systems relates to how much water can penetrate the joints, with drained and ventilated systems allowing more water to penetrate. However, the definitions are relatively vague, and the distinction has become somewhat blurred.

Rainscreen cladding can be fabricated from metal sheeting such as aluminium, stainless steel, zinc, copper and so on, or can be a formed from metal composite materials (MCM) which consist of two skins of metal (such as aluminium, or ACM) bonded to either side of a lightweight core such as polyethylene (PE) or polyurethane (PUR), a profiled metal core or a mineral core. Other materials, such as terracotta, brick slips, stone, timber and so on are also used.

Rainscreens are generally cost-effective, lightweight, and easy to install, maintain and replace. Some systems are simply ‘clicked’ onto supporting rails without the need for additional fixings. They can be used on new-build and refurbishment projects.

[edit] Related articles on Designing Buildings

- ACM cladding.

- ACM cladding testing by BRE.

- Barrier wall system.

- Celotex RS5000 PIR insulation.

- Cladding.

- Crinkly tin.

- Curtain wall.

- Dynamic façade.

- Fire performance of external thermal insulation for walls of multistorey buildings, third edition (BR 135).

- Grenfell Tower fire.

- Infill panel walls.

- Louvre (or louver).

- Louvre specifications.

- Metal composite panels.

- Metal profile cladding.

- Natural stone cladding.

- Patent glazing.

- Rainwater.

- Rainwater goods.

- Sandwich panel.

- Summerland disaster.

- The Cube.

- The effects of subframe systems on the overall thermal performance of external rainscreen walls.

- Wall types.

- Weatherboarding.

Quick links

[edit] Legislation and standards

Fire Safety (England) Regulations 2022

Regulatory Reform (Fire Safety) Order 2005

Secondary legislation linked to the Building Safety Act

Building safety in Northern Ireland

[edit] Dutyholders and competencies

BSI Built Environment Competence Standards

Competence standards (PAS 8671, 8672, 8673)

Industry Competence Steering Group

[edit] Regulators

National Regulator of Construction Products

[edit] Fire safety

Independent Grenfell Tower Inquiry

[edit] Other pages

Building Safety Wiki is brought to you courtesy of: