Aluminium

Contents |

[edit] Introduction

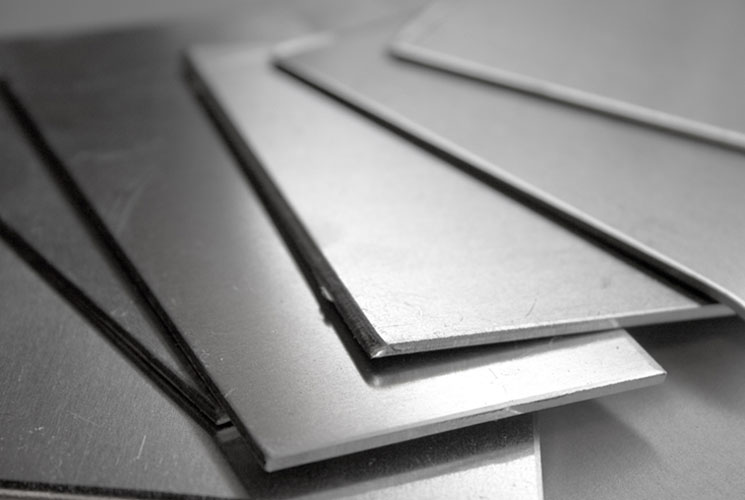

Aluminium makes up more than 8% of the Earth’s core mass and is the most widespread metal. It is also the third most common chemical element after oxygen and silicon. It is the 13 element on the Periodic Table and has a silvery-white appearance.

Pure aluminium does not occur in nature because it binds very easily with other elements. It is because of this that aluminium was only discovered in the 19th century when scientists were able to break down chemical compounds into their elements.

Because of the high costs of the extraction process, it wasn't until the late 19th century that it was possible to produce aluminium on an industrial scale for use in construction and other industries.

[edit] Extraction process

Aluminium is relatively expensive because of the amount of energy required for its extraction. It is extracted from aluminium oxide, a white powder which is purified from aluminium ore (bauxite).

The aluminium oxide is dissolved in molten cryolite (an aluminium compound that has a lower melting point than aluminium itself). Aluminium is then extracted by a process of electrolysis or electrolytic reduction. Electricity is passed through the liquid, and aluminium forms at the negative electrode. It then sinks to the bottom of the tank, where it can be tapped off.

[edit] Properties of aluminium

One of the main reasons for aluminium’s widespread application is its combination of properties:

- Lightweight: Almost three times lighter than iron.

- Durable: Almost as durable as steel.

- Ductile: Extremely flexible and easily processed using pressure when hot or cold.

- Corrosion-resistant: Its surface is protected by an extremely thin yet very strong layer of aluminium oxide.

- Non-magnetic.

- Excellent conductivity.

- Fire-resistant.

- Non-toxic.

- Bonds with other elements relatively easily, enabling the formation of a wide variety of aluminium alloys.

- Re-usable: Aluminium and its alloys can be melted down and reused without any impact on their mechanical properties. Estimates suggest that around 75% of all aluminium produced is still in use in some form.

[edit] Aluminium in construction

As the extraction process is relatively expensive, aluminium was generally not used in construction until the early-20th century. In the 1920s, it began to be used primarily for decorative detailing and Art Deco structures. In the 1930s, a breakthrough was achieved when the Empire State Building used aluminium for much of its interior structures and its famous spire. Subsequently, it began to be used for roofing, flashing, wall panels, spandrels, and so on.

Today, aluminium is the second most used metal in buildings after steel.

Because of its ductility, aluminium can be formed into many shapes and profiles. Aluminium wall cladding systems are commonly used for building exteriors, with large wall panels requiring fewer joints, resulting in time-efficient installation.

Some of the most common applications for aluminium are:

- Window and door frames.

- Rolling shutters and sun shading elements.

- Long-span roof systems covering large areas such as halls and auditoriums.

- Structures located in inaccessible places where the economy of transport and ease of installation are important, such as electrical transmission towers.

- Structures in corrosive or humid environments, such as swimming pools, bridges, hydraulic structures, offshore superstructures, and so on.

- Structures with moving sections, such as moving bridges.

- Structures to which access for maintenance is limited, such as masts, lighting towers, antenna towers, and so on.

[edit] Related articles on Designing Buildings

- Alloy.

- Aluminium decking.

- Bauxite.

- Cast iron.

- Copper.

- Failure of metals.

- Flashing.

- Galvanised steel.

- Iron.

- Lead.

- Metal.

- Metal fabrication.

- Metal roofing.

- Stainless steel.

- Types of metal.

- Zinc.

[edit] External resources

- Aluminium Leader - What is aluminium?

Featured articles and news

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

Comments