Plywood

Contents |

[edit] Introduction

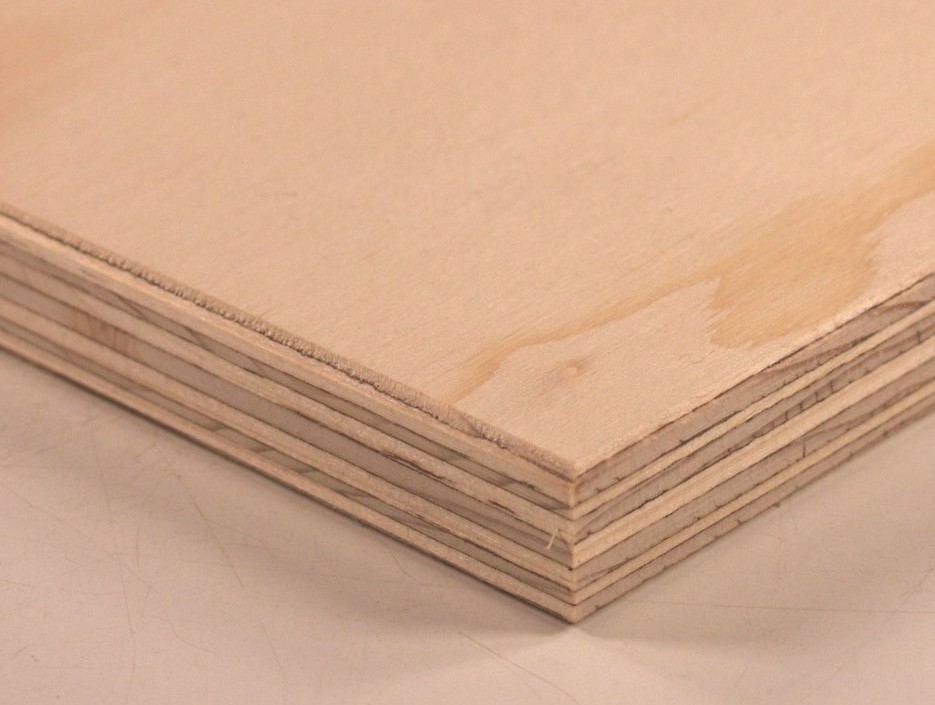

Plywood (sometimes referred to simply as ‘ply’) is an engineered sheet timber product that is widely used for construction purposes. It is manufactured from three or more thin layers of wood veneer, or ‘plies’, that are glued together to form a thicker, flat sheet. It is economical, capable of being produced to precise dimensions and is relatively resistant to warping and cracking.

Some of the most common uses of plywood include:

- Light partition or external walls.

- Formwork.

- Furniture.

- Flooring.

- Structural systems.

- Light doors and shutters.

Types of plywood include:

- Structural plywood: Used in permanent structures where high strength is needed, such as beams, formwork and bracing panels.

- External plywood: Used on exterior surfaces where a decorative or aesthetic finish is important.

- Internal plywood: Used for aesthetic finishing of non-structural applications such as wall paneling and ceilings.

- Marine plywood: Water resistant plywood that is used in shipbuilding and in parts of buildings where there may be high moisture content, such as roofing or bathrooms.

[edit] Manufacturing process

Plywood is manufactured from softwoods (such as Douglas fir, pine and redwood), hardwoods (such as ash, maple and mahogany), or a combination of both.

The timber used to make plywood is prepared by steaming or dipping in hot water. It is then peeled into thin plies of between 1-4 mm by a lathe machine. It is then formed into large sheets.

Plywood consists of the face (the surface that is visible after installation), the back, and the core (which lies between the face and the back). The plies are glued together using a strong adhesive, usually a phenol or urea formaldehyde resin.

Each layer of ply is oriented with its wood grain perpendicular to the adjacent layer, rotated up to 90-degrees to one another. This is called ‘cross-graining’ and it is this that distinguishes plywood from laminated veneer lumber (LVL). In LVL, the direction of the plies is the same, whereas in plywood, the direction of the plies alternates. It is usual to have an odd number of plies so that the sheet is balanced and this helps to reduce warping.

Cross-graining reduces the tendency of the plywood to split when nailed at the edges. It also reduces expansion and shrinkage, which improves its dimensional stability, and it gives panels consistent strength in all directions.

It is possible to engineer composite plywood when thick sheets are required. In this case, a core of solid timber pieces or particleboard is used, with a wood veneer for the face and back.

The durability of the face and back veneers can be improved by the addition of a thin outer layer that resists moisture, abrasion and corrosion, as well as making it easier to apply paint and dye. Some of the materials that can be used include plastic, resin-impregnated paper, fabric, Formica, and metal.

[edit] Properties

Plywood has several properties that make it a useful and popular construction material.

[edit] High strength

Plywood combines the structural strength of the timber from which it is manufactured, with the properties obtained from its laminated design. Cross-graining allows the sheet to resist splitting and provides uniform strength for increased stability.

[edit] High panel shear

The odd number of veneer layers that comprise plywood mean that it is resistant to bending. By increasing the panel shear of plywood, it can be used in bracing panels and fabricated beams.

[edit] Flexibility

Plywood can be manufactured to fit a wider range of requirements than cut timber. Veneer thicknesses can vary from a few millimetres to several inches, and the number of veneers used can be increased as required in terms of strength.

[edit] Moisture resistance

Plywood is relatively resistant to moisture and humidity due to the type of adhesive that is used in the binding process. This can make it suitable for exterior use such as cladding, sheds, concrete formwork and in marine construction. The veneers are prevented from warping, shrinking or expanding on exposure to water and temperature by the cross lamination.

[edit] Chemical and fire resistance

Plywood can be treated with preservatives which make it resistant to corrosion when exposed to chemicals. Chemical coatings can also increase plywood’s resistance to fire.

[edit] Impact resistance

Cross lamination gives plywood high tensile strength which makes it capable of withstanding overloading by up to twice its designated load. This makes it suitable for use in flooring systems and formwork.

[edit] Insulation

Plywood’s high thermal and sound insulation qualities make it suitable for flooring, ceilings, roofing and wall cladding.

[edit] Related articles on Designing Buildings Wiki

- Adhesives.

- Cedar.Confederation of Timber Industries.

- Chipboard.

- Cross-laminated timber.

- Engineered bamboo.

- Engineered wood products.

- Glulam.

- Laminated veneer lumber LVL.

- Lime wood.

- Medium density fibreboard - MDF

- Modified wood.

- Oriented strand board.

- Panelling.

- Softwood.

- Subfloor.

- Timber.

- Timber construction for London.

- Timber preservation.

- Timber vs wood.

- Types of timber.

[edit] External references

- Understand construction - Plywood

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Comments