Engineered wood products

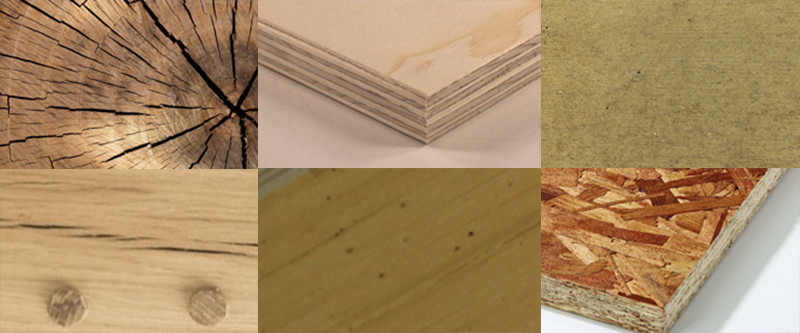

Engineered wood products (EWP) now covers a wide range of different wood based products, with a wide variety of applications. The names of which may vary depending on origin and the descriptive inclusion of for example the terms wood or timber (normally UK based) or lumber (normally US and Canada), in some cases adopted under both versions of English for example in the cases of Laminated Veneer Lumber (LVL). Such products include homogenous wood-based materials as well as non-homogenous products, the definition of which may also vary depending on interpretation for example in terms and inclusion of the use of and type of glue.

In general engineered wood products (EWP) might be separated into panel systems, structural systems, massive wood (heavy timber) systems, flooring, walling and roofing systems. The variety of EWPs and relevant systems may have differing structural capacities as well as fire ratings, with different expected lifespans for internal or external applications and as such product details should be investigated on a case by case basis. Likewise although the use of timber and EWP's can positively impact the sustainability of construction works, because of the carbon sequestration potential of timber based products, this should also be investigated on a case by case basis for any composite engineered product to include any glues, nails, metal fixings or extra fire protection used, as end-of-life scenarios will differ on a product by product basis.

An example might be from the Structural Timber Association guidance document Engineered wood products and an introduction to timber structural systems which defines engineered wood products as: ‘…reconstituted wood-based products which may be formed from homogenous wood-based material; for example glulam or non-homogenous products to form a composite material e.g. I joists.’ Whilst glulam might be considered as homogenous in some cases, one of its component parts is glue, the basis of which may vary in terms of its environmental impact, where as the engineered product DWL or brettstaple might be considered to be more truely as a homogenous timber based material because it is made up of only timber based components. There a wide variety of timber products available and a wide variety of terms to describe these, some of which are different terms to describe very similar products with slight variations, below is a list of possible engineered wood product terms the list is not exhaustive, nor is it definitive and terms will vary on locality and appliaction.

Types of engineered wood products (EWPs) with structural or non-structural applications may include;

- Battenboard.

- Blockboard.

- Cellular wood panel.

- Chipboard.

- Cross-laminated timber (CLT)

- Dowel laminated timber (DLT) - Brettstaple

- Engineered bamboo.

- Fibreboard.

- Flexiply / bendyply.

- Flexible MDF

- Flitch beam.

- Glue Laminated Timber (GLT - normally referred to as Glulam)

- Hardboard

- High-density fibreboard (HDF)

- Laminated strand lumber (LSL)

- Laminated veneer lumber (LVL).

- Laminate.

- Low-density fibreboard (LDF)

- Lamella board.

- Laminboard.

- Medium-density fibreboard (MDF)

- Modified wood.

- Multi-layer woodboard.

- Multiplex board.

- Nail laminated timber (NLT)

- Oriented strand board (OSB).

- Parallel strand lumber (PSL)

- Plywood A-grade

- Plywood B-grade.

- Plywood C-grade

- Plywood D-grade

- Single-layer particle board.

- Three-layer particle board.

- Graded density particle board.

- Veneered particle board.

- Structural composite lumber (SCL)

- Timber I-joists / Thin webbed joists

- Timber I-beams / Thin webbed joists

- Timber core board.

- Sandwich board.

- Structural composites.

[edit] Related articles on Designing Buildings

- Carpentry.

- Compressive strength of timber lattice columns for low-rise construction

- Engineered timber.

- Facts about forestry.

- Janka hardness rating scale.

- Laminated veneer lumber LVL.

- Nails - a brief history.

- Predicting service life of timber structures.

- Sustainable timber.

- Testing timber.

- The differences between hardwood and softwood.

- The use of timber in construction.

- Timber.

- Timber frame.

- Timber vs wood.

- Types of timber.

- Types of timber species.

- Whole life carbon assessment of timber.

- Wood around the world.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Comments

[edit] To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.