Dowel laminated timber DLT

Dowel Laminated Timber (DLT) is also know as brettstapel, literally meaning board stack in German. it is a technique of constructing large-scale solid timber panels for use as structural or non-structural elements, utilising smaller untreated sawn timber sections, which are mechanically fixed together with timber dowels.

In a similar way to traditional green oak frame the dowels are seasoned or dried, whilst the main body of timbers are not, so the have a higher moisture content, the dowels soak the moisture from their wetter surroundings and expand ensuring the dowels connection is strong and tight. In oak framing structure the dowels tend to also be made from oak, in DLT they may be made from beech or any other suitably dried hardwood, in both cases the structure and dowels dry over time creating stable established connections.

DLT is said to have been originally conceived by the German engineer Julius Natterer in around the 1970s (hence the reason it is still often referred to as brettstaple). At this time the technique consisted of low grade posts of sawn timber laid side by side, continuously nailed together to create solid structural elements, which then evolved to include glues for increased strength and wider spans. Apart from issues around end of life scenarios, the randomly placed nails also caused problems for modifying or cutting any elements.

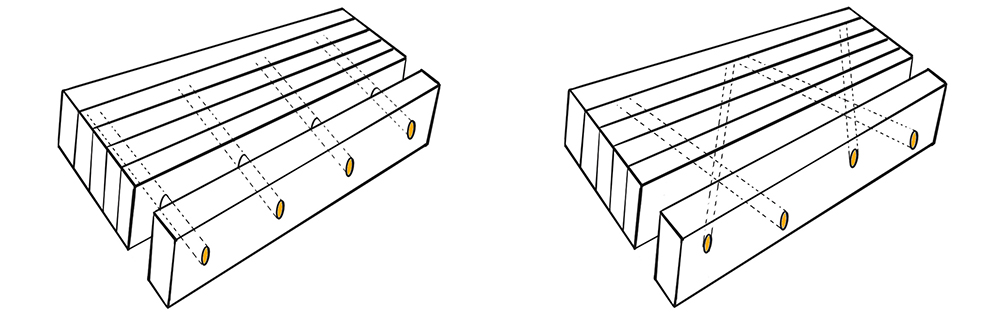

In 1999 a German company developed a dowelled wood system (Dübelholz) replacing the nails, this overcame the issues of modification and end-of life because the system became a single material solution. However contraction and expansion from variations in temperature or moisture over time, could potentially cause separation along the dowel axi, compromising strength leading to reintroduction of glue or nails.

2001 An Austrian company developed a system of inserting timber dowels at angles through the posts in ‘V’ and ‘W’ formations to solve the issue, it virtually eliminated the potential for movement gaps retaining a 100% timber product. Other manufacturers have different means of dealing with the issue, including driving dowels through rotating layers of boards, though this is perhaps the most innovative.

Today many different companies manufacture Brettstapel in Austria, Germany, Switzerland and Norway. The most common form of Brettstapel is the perpendicular dowel with the majority of systems not utilising any glue. DLT utilizes locally sourced material and does not include adhesives it can be considered a natural low carbon value engineered product.

[edit] Related articles on Designing Buildings

- Carpentry.

- Compressive strength of timber lattice columns for low-rise construction.

- Cross laminated timber.

- Nail Laminated timber.

- Engineered bamboo.

- Engineered wood products.

- Facts about forestry.

- Glulam.

- Janka hardness rating scale.

- Laminated veneer lumber LVL.

- Modified wood.

- Nails - a brief history.

- Plywood.

- Predicting service life of timber structures.

- Sustainable timber.

- Testing timber.

- The differences between hardwood and softwood.

- The use of timber in construction.

- Timber frame.

- Timber vs wood.

- Types of timber.

- Types of timber species.

- Whole life carbon assessment of timber.

- Wood around the world.

[edit] External Links

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Comments

[edit] To make a comment about this article, or to suggest changes, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.