Design for deconstruction, ski slope

This article was written by Kathryn Adams, Principal Consultant at BRE. It originally appeared in --BRE Buzz on 11 Feb 2016, Design for Deconstruction: Case Study : Ski slope.

It is one of a series of case studies that use a new methodology to assess the deconstruction potential of new build properties. The case studies and methodology have been funded by the BRE Trust to raise awareness amongst architects, designers and contractors of the potential of Design for Deconstruction (DfD) to create more sustainable buildings and lead to better deconstruction outcomes.

Contents |

[edit] Introduction

This an unusual type of building within the UK which accommodates an 8,000m2 air tight box indoor skiing area with a 160m main slope and a 100m nursery slope. There is also an amenities building which incorporates a three-storey ‘warm side’ area with shops, restaurants and equipment hire facilities. It was built from 2008 to 2009.

[edit] Building description

A concrete floor slab was used with a steel frame and concrete retaining walls. To avoid any danger of heave caused by freezing on the slope below the floor slab, heating pipes were embedded in a light layer of concrete to maintain a constant temperature in the surrounding ground. A key requirement was to provide good levels of thermal insulation in a tough environment, similar to a cold store requirements.

The roof is a gentle, straight pitched roof (rather than domed) and the amenities building has a mono-pitch roof of the same, both with a ‘nature roof’ design. The key construction challenge was working on the sloping ski floor, which starts 32 m above the building’s ground floor level at a pitch of 15 degrees. This will also have implications during deconstruction. The total floor space of the building is approximately 10,500 m2. The building’s specification is summarised as follows:

- Frame: Main ski block - Steel portal frame; Amenity block - Concrete frame up to first floor steel frame above.

- Foundation: Concrete pad foundation.

- Ground floor: In-situ concrete slab, 75 mm thick extruded polystyrene foam boards fixed in two layers deep on the ski slopes.

- Upper floor: In-situ concrete floor on metal deck. Timber decking on metal joists.

- External walls: Rain screen cladding (timber, flat/profiled sheets), structurally insulated 150 mm backing panels, screwed on to concrete frame, aluminium curtain wall glazing.

- Internal walls: Metal stud partition walls, plaster board, paint.

- Roof: Green roof, aluminium insulated composite panel on metal roof structure.

- Windows: Powder coated aluminium windows, double glazed, aluminium window sill.

- Floor finishes: Rubber flooring, vinyl flooring and carpet tiles.

- Cladding: Siberian larch with one coat of solvent, aluminium profile and flat panel composite cladding.

- Sanitary ware: Ceramic dual flush WC; sink with low flow taps; wet room with ceramic tiling.

- Services: Air handling units.

- Fixtures and fittings: Fitted chipboard kitchen units including cabinets, steel staircase and balustrading, aluminium flashing.

[edit] Project documentation

As a standardised industrial building construction, a step-by-step sequence was followed during construction, and the same principles will have to be applied for deconstruction. Risk assessment records, produced as part of CDM regulations compliance, hold the information for maintenance as well as dismantling the structure.

There was no clear brief or commitment within the project brief to design for deconstruction. Therefore, no active allocation of responsibility for ensuring design for deconstruction was made within the project team.

Handover documentation include ‘as built’ construction details but not the sequence of erecting different elements. The contractor has a visual recording of the construction and installation of each components and sub-components; however, this was not handed over to the client.

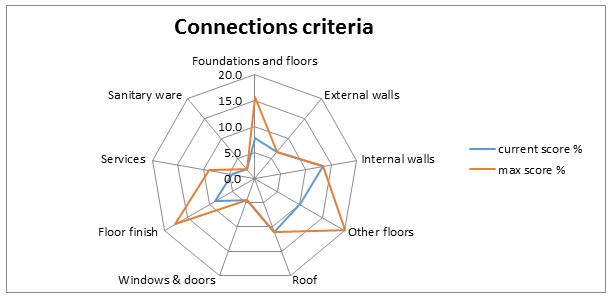

[edit] Connections

Overall score 69%

All of the structural steel framework across the building was delivered in sections and bolted together on site, enabling them to be unbolted for reuse. The timber cladding was nailed to timber battens, which were bolted onto the steel frame. The flat panel metal rain screen cladding was riveted to the base frame. The mechanical fixings will aid in undertaking deconstruction.

All of the structural steel framework across the building was delivered in sections and bolted together on site, enabling them to be unbolted for reuse. The timber cladding was nailed to timber battens, which were bolted onto the steel frame. The flat panel metal rain screen cladding was riveted to the base frame. The mechanical fixings will aid in undertaking deconstruction.

The structural steel frames were bolted into the concrete pillars or the foundations; in some places it was set within the concrete retaining walls. The geometry of the components edges in relation to the connection design will dictate whether or not the components can be disassembled. A lightweight 100 mm green roof on rubber drainage matting was simply laid on top of the metal deck roofing, allowing for easy removal (see figure above).

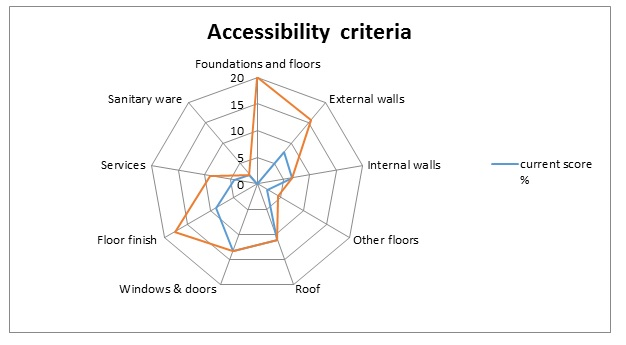

[edit] Accessibility

Overall score 57%

An external roof walkway gives full accessibility for maintenance. As seen in the figure above, all high level lights are accessible from the central service corridor at roof level. Access to the external wall cladding and gutter cleaning can be carried out using scissor lifts. All internal finishes in the amenity block can be soft stripped as and when a refit is required or at end of life.

An external roof walkway gives full accessibility for maintenance. As seen in the figure above, all high level lights are accessible from the central service corridor at roof level. Access to the external wall cladding and gutter cleaning can be carried out using scissor lifts. All internal finishes in the amenity block can be soft stripped as and when a refit is required or at end of life.

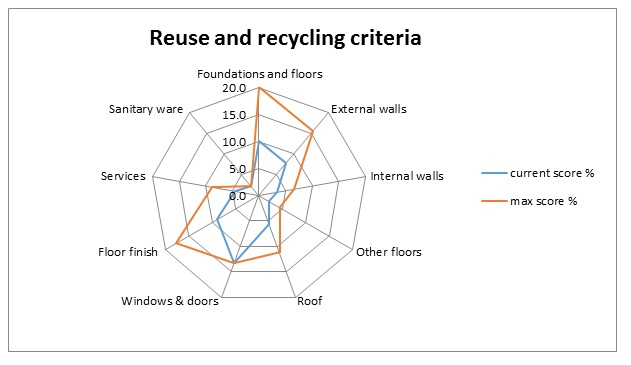

[edit] Reuse and recycling potential

Overall score 58%

The primary material types used in the building were; concrete, steel, metal stud, glass and cladding of timber and aluminium. The steel frames could be reused, for a project of a similar construction. The cladding could also be reused.

The primary material types used in the building were; concrete, steel, metal stud, glass and cladding of timber and aluminium. The steel frames could be reused, for a project of a similar construction. The cladding could also be reused.

The mineral wool, extruded polystyrene insulation, the insulated panel backing and the composite metal roof are difficult to recycle currently. The rubber and vinyl flooring are unsuitable for reuse. The vinyl flooring can be recycled. The carpet tiles can be reused.

The majority of materials including timber cladding, aluminium components and structural steel can be easily retrieved during maintenance/demolition for reuse.

The concrete floor and foundation could be recycled as aggregate, depending on whether it is possible to separate and sort steel and concrete cost-effectively.

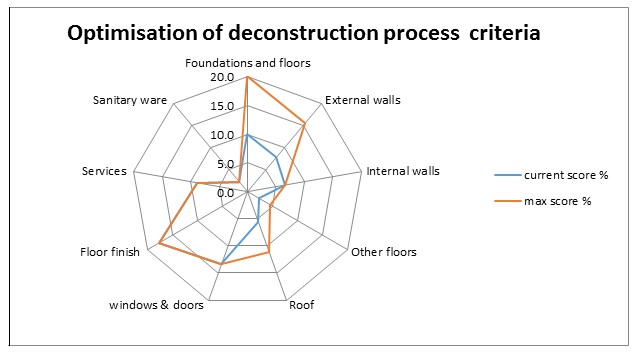

[edit] Optimisation of deconstruction

Overall score 66%

The concrete ski floor should be removed first to give access for scaffolding in order to remove any internal service, fixtures and fittings. Where structural steel frames are cast into retaining walls, they would have to be cut-off at the base in order to recycle or re-use. Cladding panels are all screwed, except the flat panel rain screen cladding which is riveted, and can be dismantled using a standard removal process.

The concrete ski floor should be removed first to give access for scaffolding in order to remove any internal service, fixtures and fittings. Where structural steel frames are cast into retaining walls, they would have to be cut-off at the base in order to recycle or re-use. Cladding panels are all screwed, except the flat panel rain screen cladding which is riveted, and can be dismantled using a standard removal process.

[edit] Fixture and fittings

The building services (air handling units and condensers), were pre-mounted on to steel decking modules (6×7.5m) and bolted together on-site. Individual plant could be lowered down in the same way as it was installed. Internal finishes (carpet tiles, doors and windows) can be removed easily. The main staircase is constructed from steel sections with steel balustrades, which can be unbolted and reused.

[edit] Summary

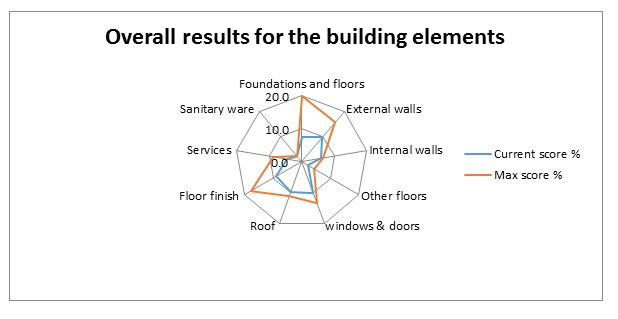

The ski slope case study scored 61% overall for its DfD potential. The third figure shows the overall score by element. Elements which had greater potential for DfD were the steel frames, the cladding, the services and a number of the internal finishes. The connections criteria (69%) and the optimisation of the deconstruction process (66%) scored the highest and access the lowest (57%). A large number of mechanical fixings have been used which will aid the deconstruction process, as well as having accessibility a key requirement for operation maintenance.

The ski slope case study scored 61% overall for its DfD potential. The third figure shows the overall score by element. Elements which had greater potential for DfD were the steel frames, the cladding, the services and a number of the internal finishes. The connections criteria (69%) and the optimisation of the deconstruction process (66%) scored the highest and access the lowest (57%). A large number of mechanical fixings have been used which will aid the deconstruction process, as well as having accessibility a key requirement for operation maintenance.

The key issues are:

- Steel frames lend themselves for reuse. They are usually tested for their strength properties and coatings will be removed; they can then be re-fabricated which may involve cutting to new lengths. For this case study, the frame will have to be cut where it is set in the concrete retaining wall.

- Due to the use of rivets, bolts and nails for the cladding, it should be relatively easy to de-mount these for reuse.

- Whilst the green roof could be reused as it is simply laid onto the metal decking roof, it is currently unknown if this a viable option, as it is a relatively new construction type, with few cases reaching end of life.

- A number of materials are difficult to recycle, currently including the mineral wool, extruded polystyrene insulation, the insulated panel backing, composite metal roof and rubber flooring. More consideration should be given to products which are easier to recycle at end of life.

- The building services can be deconstructed in the same way they were constructed; however these details may be missing when the building reaches its end of life.

--BRE Buzz

See other articles by BRE Buzz here.

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

- Adapting 1965-1980 semi-detached dwellings in the UK to reduce summer overheating and the effect of the 2010 Building Regulations.

- Airtightness of energy efficient buildings.

- Anatomy of low carbon retrofits: evidence from owner-occupied superhomes.

- BRE articles on Designing Buildings Wiki.

- BRE National Solar Centre.

- BRE Üserhuus.

- Building Research Establishment BRE.

- Design for deconstruction.

- Design for deconstruction, BRE modular show house.

- Design for deconstruction, office building.

- Pre-demolition and pre-refurbishment audits.

- Qualitative research and the built environment.

- Structure relocation.

- The Hive.

Featured articles and news

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.