MEP Systems for Scan-to-BIM Projects

[edit] Building Information Modelling and Scan-to-BIM

Building Information Modelling has transformed the architecture, engineering, and construction (AEC) industry by creating detailed digital representations of buildings. BIM goes beyond basic 3D modelling by integrating comprehensive data about a building's structure and systems. It enhances the design and construction process by offering a unified model that reflects both the geometry and the functional aspects of a building.

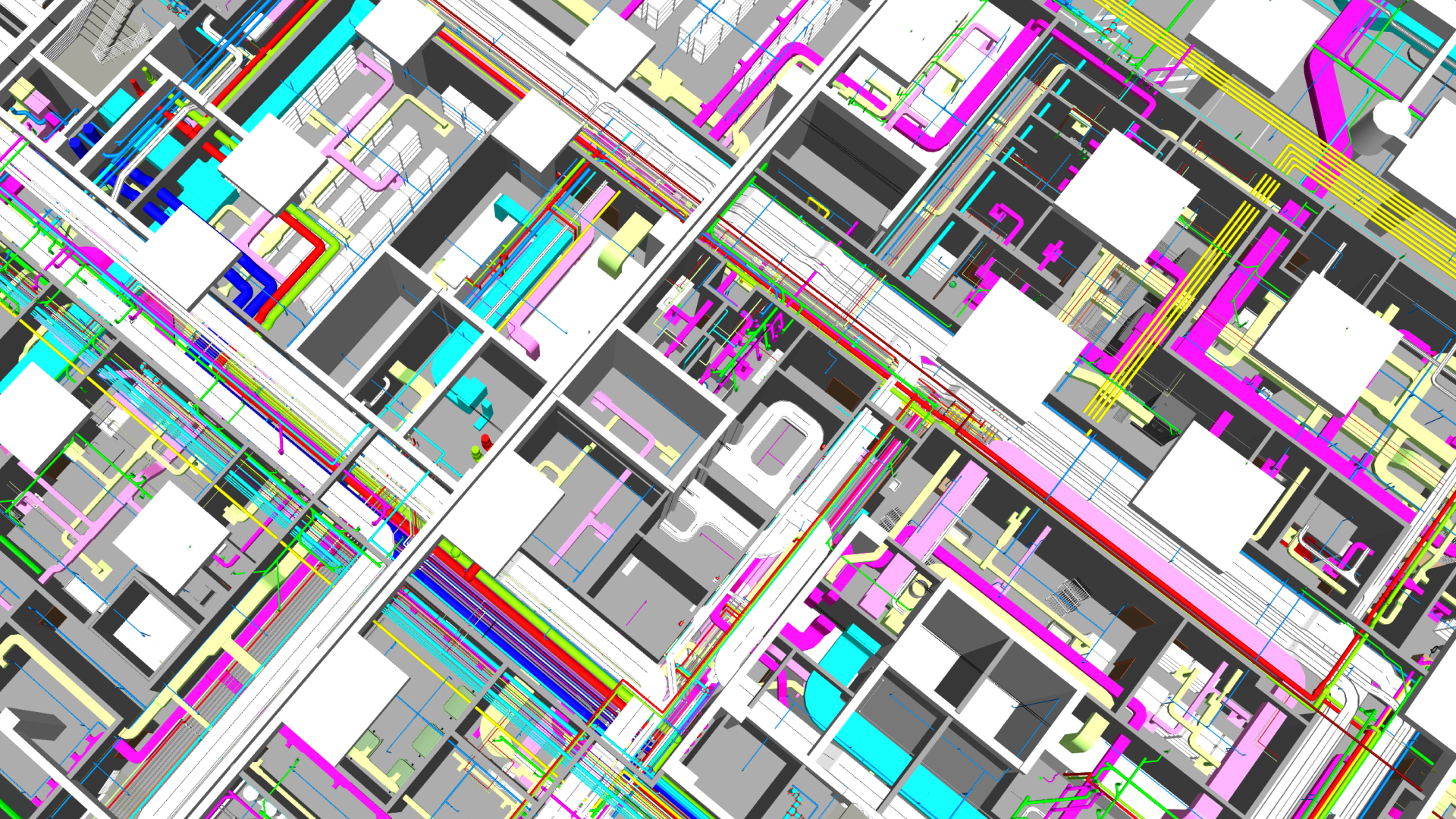

However, Scan to BIM Services use laser scanning to capture detailed spatial data of existing MEP (Mechanical, Electrical, and Plumbing) systems and convert it into accurate 3D models. This process creates a comprehensive Building Information Model (BIM), which integrates all MEP components for precise planning and coordination. The model helps visualise system placement within the building’s infrastructure, identify potential conflicts, and streamline the design and installation process.

[edit] Key features of BIM

- Parametric Modelling: BIM updates all related elements automatically when changes are made to a single component. This keeps the entire model consistent.

- Improved Collaboration: BIM provides a shared model that integrates input from various disciplines, including architecture, structural engineering, and MEP (Mechanical, Electrical, and Plumbing).

- Lifecycle Management: BIM supports the entire building lifecycle, from initial design through construction to ongoing maintenance and operations. It acts as a central repository for crucial information.

Scan-to-BIM uses 3D laser scanning to capture precise details of existing buildings. This technology produces detailed point clouds that are converted into BIM models. The main aspects of Scan-to-BIM include:

- High-Resolution Scanning: This technology captures fine details of a building's structure.

- Data Conversion: Point clouds are processed into formats compatible with BIM, ensuring accurate digital models of the existing conditions.

- Accuracy: The precision of the scanning equipment and data processing is crucial for creating reliable models that match the real-world conditions.

[edit] Scan-to-BIM

Scan-to-BIM offers several benefits

- Enhanced Accuracy: It provides detailed data, leading to precise BIM models.

- Efficient Documentation: The technology creates thorough as-built records, which are important for renovation, retrofitting, or maintenance.

- Conflict Detection: It helps identify discrepancies between existing conditions and new designs, reducing errors and rework.

- Better Planning: By offering detailed views of current conditions, Scan-to-BIM supports improved decision-making throughout a project.

Scan-to-BIM is useful in various contexts:

- Renovation and Retrofits: It helps plan and execute changes by accurately representing existing conditions.

- Historical Preservation: It creates detailed models of historic buildings for future reference and conservation efforts.

- Facility Management: It provides current models that assist in managing and maintaining existing facilities, including MEP systems.

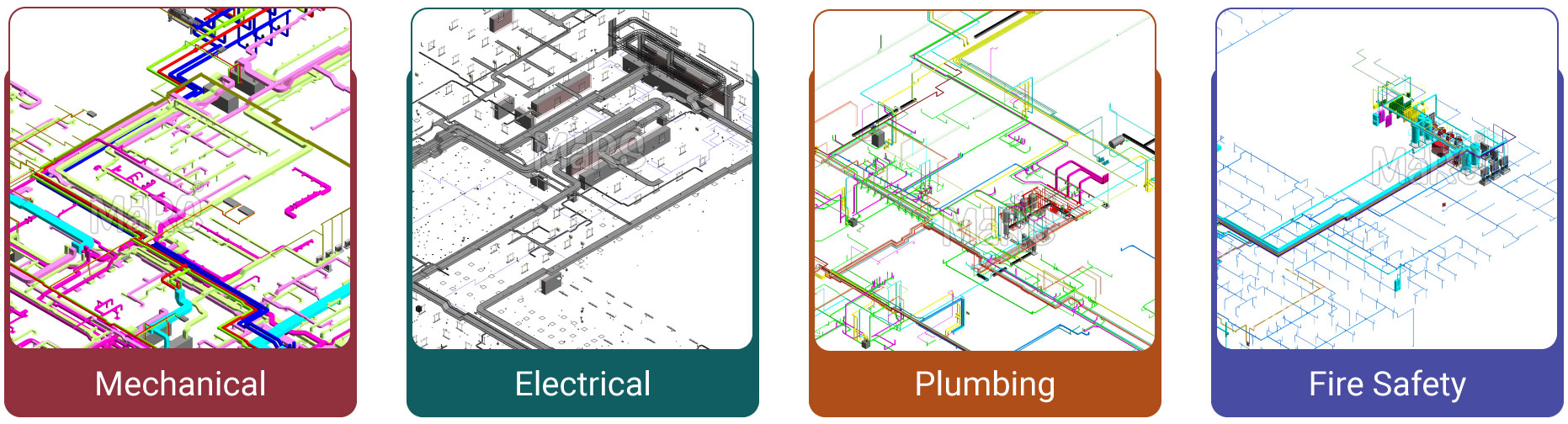

[edit] Mechanical, Electrical, and Plumbing (MEP) Systems in Scan-to-BIM

Mechanical, Electrical, and Plumbing (MEP) systems are fundamental to the operation and efficiency of buildings. In Scan-to-BIM projects, accurately representing these systems is essential for effective design, installation, and maintenance. MEP systems encompass heating, ventilation, and air conditioning (HVAC),and fire safety systems, which ensure indoor comfort; electrical systems that handle lighting and power distribution; and plumbing systems responsible for water supply and waste management. Each system plays a crucial role in building performance and must be meticulously modelled to guarantee proper integration and functionality.

[edit] MEP Systems

- Mechanical Systems

- Heating, Ventilation, and Air Conditioning (HVAC)

- Electrical Systems

- Plumbing Systems

- Fire Safety

In MEP BIM Services, Integrating MEP systems into BIM using scan technology presents several challenges. The complexity of MEP systems, often densely arranged within building spaces, requires high-resolution scanning and precise data processing to accurately capture their layout and interactions. Ensuring data accuracy is critical. Any errors or omissions in the scan data can lead to inaccuracies in the BIM model, impacting subsequent design and installation processes. Additionally, MEP systems must be coordinated with architectural and structural elements. Identifying and resolving conflicts early in the design process is essential to prevent costly rework and ensure smooth project execution.

[edit] Scan-to-BIM Integration

These challenges, Scan-to-BIM offers substantial benefits for MEP systems. High-resolution scans provide detailed and accurate representations of existing systems, resulting in precise BIM models. This integration improves coordination between MEP systems and other building components, reducing conflicts and enhancing overall design efficiency. Accurate modelling also supports effective space management and streamlines maintenance processes. Facility managers benefit from comprehensive BIM models that offer clear views of system layouts and components, aiding in operational efficiency and troubleshooting.

[edit] Challenges

- Complexity

- High-Resolution Scanning

- Detailed Data Processing

- Accuracy

- Architectural

- Structural Elements

- Conflicts

Scan-to-BIM technology is particularly valuable in retrofit projects, where accurate as-built models of existing MEP systems are crucial for planning renovations without disrupting ongoing operations. In new construction, integrating scan data ensures that MEP systems are installed according to design specifications and helps identify any discrepancies early in the process. For facilities management, precise BIM models facilitate ongoing maintenance and operational efficiency by providing reliable information about system components and their locations.

[edit] Data Accuracy and Integration

MEP systems into BIM projects begins with capturing detailed scan data of the existing MEP infrastructure. This initial step is essential for creating an accurate digital representation of mechanical, electrical, and plumbing components within a building.

Capturing Detailed Scan Data: Advanced scanning technologies, such as laser scanners or photogrammetry, are employed to collect high-resolution data on MEP systems. These tools provide precise measurements, spatial relationships, and conditions of various components. Ensuring accuracy at this stage is critical as this scan data forms the foundation of the digital model.

Data Processing and Conversion: After acquiring the raw scan data, it must be processed and converted into a format suitable for the BIM model. Specialised software is used to transform point cloud data into 3D models that accurately reflect the physical attributes and layout of MEP systems. This conversion step involves translating real-world observations into a functional digital environment.

Ensuring Data Accuracy: Maintaining the integrity of the digital model requires thorough verification to ensure it aligns with the physical MEP components. This involves cross-checking scan data with physical measurements and existing documentation to identify and rectify any discrepancies. Accurate representation is crucial for ensuring that the BIM model remains reliable and effective.

Integration with BIM Models: Once processed, the MEP data is integrated into the BIM model, ensuring that it coordinates properly with the building’s architectural and structural elements. Advanced BIM tools assist in positioning MEP components accurately, ensuring seamless integration and coordination with other building elements.

Benefits of Accurate Data Integration: Accurate representation of MEP systems in BIM models significantly enhances design and construction processes. It helps prevent conflicts between MEP systems and other building elements, improves overall coordination, and supports informed decision-making. An accurate BIM model also leads to greater operational efficiency and reduces errors and rework during construction and facility management.

[edit] Coordination and Clash Detection

Managing spatial conflicts between Mechanical, Electrical, and Plumbing (MEP) systems and other building elements is a major challenge in Scan-to-BIM projects. Advanced clash detection tools are essential for addressing this issue. These tools check the digital model to find potential problems between MEP components and other parts of the building before construction or renovation begins.

Advanced Clash Detection Tools: Software applications designed for clash detection use complex algorithms to compare different parts of the BIM model. These tools can find overlaps and other problems between MEP systems and the building’s structure. For example, conflicts might occur if a duct intersects with a structural beam or if plumbing pipes are placed in hard-to-reach areas.

Resolving Conflicts Early: Effective clash detection allows problems to be fixed during the design phase, before construction starts. By dealing with issues in the digital model, the likelihood of costly and time-consuming problems on-site is greatly reduced. This proactive approach helps make the construction process smoother and cuts down on the need for rework.

Coordination of MEP Systems: Proper coordination ensures that MEP systems do not interfere with each other or with other building elements. This means aligning ductwork, electrical wiring, and plumbing to avoid spatial conflicts and ensure everything works well together. Clash detection tools help with this by providing detailed reports and visualisations of potential issues.

[edit] Workflow Integration and Tools

Adding MEP workflows into Scan-to-BIM processes requires using specialised software and following industry standards. Several tools and methods are used to smoothly add MEP data into the BIM environment.

Specialised Software: Different BIM software solutions offer features specifically for MEP integration. These tools help with detailed modelling, analysis, and simulation of MEP systems within the overall building model. For example, Revit MEP and Navisworks are popular for their abilities in modelling and clash detection.

Standards and Methods: The process involves following industry standards and guidelines to ensure consistency and accuracy. Standards like the National BIM Standard (NBIMS) provide frameworks for how data should be represented, coordinated, and shared.

Detailed Analysis and Simulation: Advanced tools allow for analysing and optimising MEP systems. Simulation features help evaluate system performance under various conditions, which helps find possible improvements and ensures efficiency. For example, energy modelling tools can show how different HVAC setups affect building performance.

Workflow Coordination: Managing MEP workflows efficiently means coordinating between different disciplines and aligning processes to keep data consistent. This involves ensuring that MEP modelling fits well with architectural and structural elements so that all components are accurately represented and coordinated within the BIM environment.

[edit] Significance and Benefits

[edit] Enhanced Design Accuracy

- Clear Visualisation: Integrating MEP systems into a Scan-to-BIM model provides a clear and detailed 3D view of how mechanical, electrical, and plumbing systems fit within a building. This clarity helps designers spot potential problems before construction begins.

- Precise Measurements: Scanning technology captures exact dimensions of MEP systems, making sure they match up with the building's design. This accuracy helps avoid mistakes and ensures everything fits together as planned.

[edit] Improved Coordination

- Better Communication: A unified BIM model allows architects, engineers, and contractors to work from the same plan, making communication smoother and reducing misunderstandings.

- Conflict Resolution: Using clash detection tools in the digital model helps identify and fix problems where MEP systems might interfere with other building elements. This proactive approach saves time and avoids expensive fixes later on.

[edit] Increased Operational Efficiency

- Optimised Performance: The BIM model lets designers run simulations to make sure MEP systems work efficiently. For example, HVAC systems can be adjusted to improve energy use and comfort.

- Easier Maintenance: A detailed digital model provides valuable information for managing and maintaining the building. It helps locate components quickly and plan for repairs or upgrades.

[edit] Cost Savings

- Less Rework: By catching design issues early in the digital model, the need for costly changes during construction is reduced. This means fewer unexpected expenses and delays.

- Smarter Resource Use: Accurate data from the BIM model helps in estimating materials and labour more precisely, leading to better resource management and cost savings.

[edit] Better Decision-Making

- Informed Choices: The detailed information in a Scan-to-BIM model helps make better design decisions. It provides a solid foundation for choosing the best solutions and identifying areas for improvement.

- Lifecycle Management: The BIM model supports the building’s entire lifecycle, from construction to ongoing maintenance. It’s a reliable resource for future upgrades or changes.

[edit] Enhanced Building Performance

- Energy Efficiency: The BIM model helps design MEP systems that are more energy-efficient, reducing both operational costs and environmental impact.

- Comfort and Safety: Well-integrated MEP systems contribute to a better indoor environment by ensuring effective heating, cooling, lighting, and ventilation.

[edit] Future Trends and Innovations in Scan-to-BIM and MEP Systems

[edit] Integration with Advanced Technologies

- Artificial Intelligence and Machine Learning: The integration of AI and ML into Scan-to-BIM processes is poised to significantly enhance the efficiency and effectiveness of building modelling. AI algorithms can analyse vast datasets to identify patterns and optimise MEP system designs, while machine learning models can anticipate potential issues based on historical data, allowing for proactive problem-solving and improved decision-making.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies offer immersive and interactive experiences that can greatly enhance the visualisation of MEP systems within their building context. AR provides real-time overlays of digital information on physical spaces, aiding in design reviews and client presentations, whereas VR creates fully immersive simulations that facilitate comprehensive design analysis and stakeholder engagement.

[edit] Development of Smart Building Technologies

- Internet of Things (IoT): IoT technology, when integrated with BIM models, enables continuous monitoring and management of MEP systems. Real-time data from IoT sensors can enhance building performance and operational efficiency by providing insights into system functionality and enabling predictive maintenance.

- Building Automation Systems (BAS): Integrating BAS with BIM allows for the automation and optimisation of MEP system controls. This integration supports improved energy management and occupant comfort by dynamically adjusting system settings based on real-time data, leading to more sustainable and efficient building operations.

[edit] Advances in Scan-to-BIM Technology

- High-Definition Scanning: Advances in scanning technology, such as higher resolution and faster data capture, improve the accuracy and detail of Scan-to-BIM projects. High-definition scans ensure that BIM models precisely reflect the existing conditions of buildings, enhancing the reliability of the digital representations.

- Mobile Scanning Devices: The development of portable scanning devices facilitates data collection in challenging or confined spaces. These mobile tools offer increased flexibility and efficiency in capturing comprehensive data, further refining the accuracy of Scan-to-BIM models.

[edit] Regulatory and Standards Considerations

[edit] Industry Standards for Scan-to-BIM

- ISO Standards: Compliance with ISO standards, such as ISO 19650, ensures that Scan-to-BIM processes adhere to international best practices and quality benchmarks. These standards provide a structured framework for managing and sharing building information throughout the project lifecycle.

- National Guidelines: Adhering to national guidelines is essential for meeting local regulatory requirements and expectations. These guidelines outline standards for accuracy, data interoperability, and information sharing, ensuring that Scan-to-BIM projects align with regional practices and standards.

[edit] Compliance and Legal Issues

- Data Privacy: Ensuring data privacy is crucial in Scan-to-BIM projects, especially when dealing with sensitive or proprietary information. Compliance with data protection regulations helps safeguard stakeholder interests and mitigate legal risks associated with data management.

- Intellectual Property: Proper management of intellectual property rights related to BIM models and scan data is essential to prevent legal disputes and protect project assets. Clear agreements regarding ownership and usage rights ensure fair and legal use of digital resources.

[edit] Case Studies and Applications

Notable Projects

Project Overview: The Corporate Building BIM project by MaRS BIM Solutions exemplifies the effective application of Scan-to-BIM technology in architectural practice. This project involved the development of a detailed BIM model for a corporate building, showcasing the integration of advanced scanning and modelling techniques.

Key Highlights:

- High-Resolution Scanning: The use of high-resolution laser scanning provided precise details of the existing building structure and MEP systems, resulting in an accurate digital model.

- Data Conversion and Integration: The conversion of point cloud data into a comprehensive BIM model ensured accurate alignment with architectural and MEP components.

- Clash Detection and Coordination: Advanced clash detection tools identified and resolved conflicts between design elements and existing MEP systems, enhancing coordination and reducing errors.

- Enhanced Design and Planning: The detailed BIM model improved design decisions and planning by providing clear visualisation and precise measurements of MEP systems.

- Operational Efficiency: The BIM model facilitated efficient facility management by offering detailed information on system layouts, supporting effective maintenance and operations.

Lessons Learnt:

- Importance of Accurate Data: High-quality scan data is fundamental to creating reliable BIM models, highlighting the need for precise data capture and processing.

- Effective Coordination: Utilising clash detection tools to address conflicts early in the design phase can significantly reduce rework and ensure successful integration of MEP systems.

- Value of Detailed Models: Comprehensive BIM models enhance design, construction, and facility management processes, demonstrating the benefits of integrating detailed MEP data.

- High-Resolution Scanning: Invest in advanced scanning technology to capture detailed and accurate data, which is crucial for creating precise BIM models.

- Data Processing: Employ specialised software for converting and integrating scan data into BIM models to ensure alignment with physical and design requirements.

- Clash Detection: Use advanced clash detection tools to identify and resolve conflicts proactively, improving coordination and minimising construction errors.

Future Directions:

- Innovation in Scanning Technologies: Explore advancements in scanning technologies, such as increased resolution and mobile devices, to enhance the accuracy and efficiency of Scan-to-BIM projects.

- Integration with Smart Building Technologies: Investigate the integration of BIM models with IoT and BAS to optimise building performance and facility management, leveraging real-time data for improved operational efficiency.

[edit] Conclusion:

In conclusion, the integration of MEP systems into Scan-to-BIM projects represents a significant leap forward in building design and management. By leveraging high-resolution scanning and advanced Building Information Modelling technologies, stakeholders can achieve unparalleled accuracy in the digital representation of a building’s infrastructure. This precision not only enhances design accuracy and improves coordination among various systems but also facilitates more efficient planning and execution. The ability to detect and resolve conflicts early in the design phase helps minimise costly rework and ensures that MEP systems are installed and maintained according to precise specifications.

Looking ahead, the continued evolution of technologies such as artificial intelligence, augmented reality, and smart building systems is expected to further refine the capabilities of Scan-to-BIM methodologies. These innovations promise to enhance building performance, optimise operational efficiency, and support more effective facility management. Embracing these advancements and adhering to industry standards will be crucial for maximising the benefits of Scan-to-BIM projects, ultimately leading to more sustainable, efficient, and well-managed built environment.

--Snehal Dodha 09:53, 30 Aug 2024 (BST)

--MaRS

[edit] Related articles on Designing Buildings

- Artificial intelligence.

- Beyond BIM: Knowledge management for a smarter built environment.

- BIM articles.

- BIM and facilities management.

- BIM for mechanical electrical and plumbing drawings.

- Building information modelling BIM.

- Global BIM market.

- How BIM can cause needless early stage MEP design concerns.

- Mechanical, electrical and plumbing MEP.

- MEP Coordination.

- MEP BIM and the building lifecycle

- Revit.

- Sustainability in building design and construction.

- The sustainability of construction works.

- UsBIM.

- Integrating Scan to BIM for Sustainable Smart City Planning.

- Scan to BIM in Construction

- Scan to BIM: Everything you need to know.

BIM Directory

[edit] Building Information Modelling (BIM)

[edit] Information Requirements

Employer's Information Requirements (EIR)

Organisational Information Requirements (OIR)

Asset Information Requirements (AIR)

[edit] Information Models

Project Information Model (PIM)

[edit] Collaborative Practices

Industry Foundation Classes (IFC)