Wind cowl

Contents |

[edit] Early history

Fixed cowls were originally placed at the top of a chimney, like a hat, with slots to allow smoke to be released but preventing water or rain from entering, however, these cowls could not prevent driving wind which sometimes caused a down draft potentially blowing some dust into rooms. It is said that Charles I granted a patent to the inventor of a rotating ‘smoke cure’ during his reign, between 1625 and 1646 AD, this became known as a wind cowl, which was fitted as an add-on to prevent wind causing a down draught in the chimney.

[edit] Thriving industry

It was in 19th century that smoke cowls became established as an industry in the south of England. They were embraced by the Victorians for their practical value and decorative potential, with an array of different designs being crafted, sold, and installed.

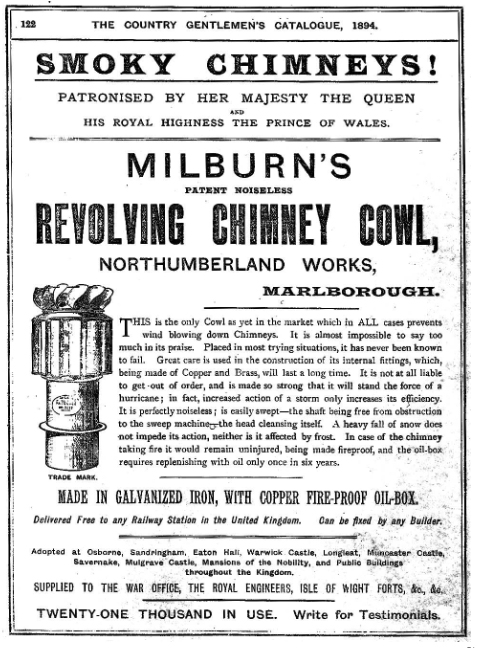

In 1829, George Ewart produced ‘The Empress’ which was exported across the British Empire although, it was sometimes less for reasons of smoke alleviation than for general ventilation. This design continued until the 1930s when its successor, ‘The Emperor’ took its place until 1956, when the firm making them finally ceased production. During that time G.A. Harvey of Greenwich and F. Braby of Fitzroy Square, London produced a selection of wind cowls, amongst which ‘The Brighton’ was the most popular.

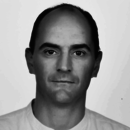

The greatest success in the field came in 1873 in Marlborough, when Joseph Milburn patented an elegant cowl with carefully specified bearings. This was a slightly complex situation, as two other people also laid claims to the design. Milburn, however, was able to influence the powerful and wealthy by encouraging the Marquis of Ailesbury to use a number of his cowls on his mansion 'Tottenham House' in the Savernake Forest. Recommendations to the nobility and gentry soon followed, resulting in the cowls being installed on nearly every large house in the country. The situation was simplified commercially when Queen Victoria granted Milburn a royal charter and Lord Bath wrote personally praising ‘The Milburns’ efficiency.

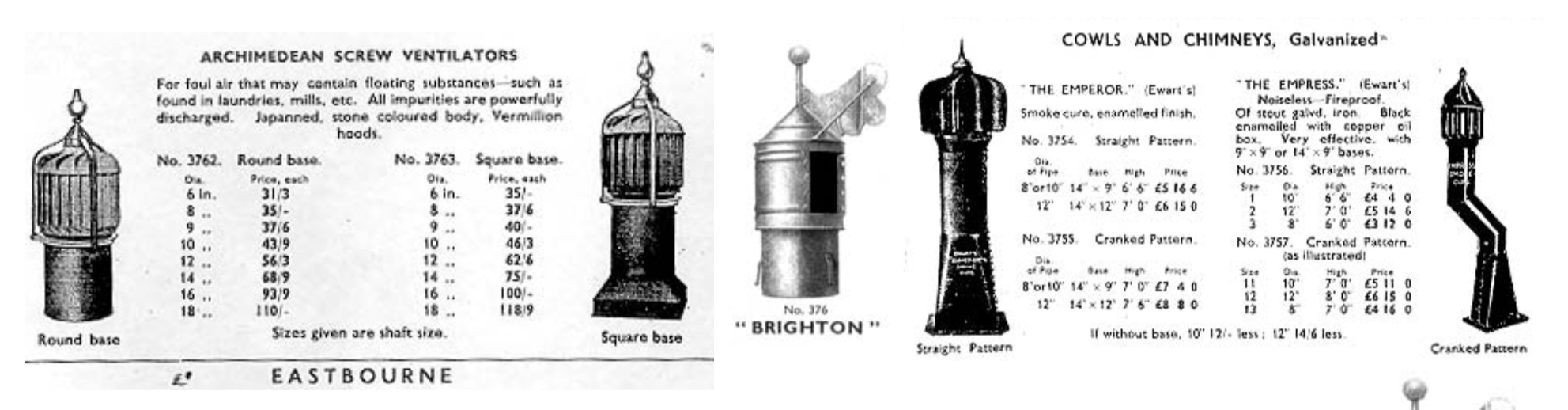

Milburn’s biggest customer was Lord St Levan. Every two years a cartload of cowls would arrive at Marazion, opposite St Michael’s Mount, Cornwall where he lived and where the winds used to remove the lids of other cowls and blow them into the sea. The Milburn was the only cowl that could withstand the harsh weather and remain effective. They were generally 6 feet high and between 8 and 12 inches in diameter and made of galvanized iron or unpainted copper. Each cowl had a brass plate riveted to it, carrying its details and serial number. From 1873 each cowl’s date of dispatch, destination, modifications, and specifications with drawings and details were entered into the company’s ledgers. Over 55,000 entries were made between the firm starting up and the last recorded serial number. Ownership changes in 1960 led to the disposal of many documents - now lost forever.

[edit] Skyline of variety

Three firms in Brighton dominated the cowl industry, developing various styles and designs for transportation and installation around the UK and even abroad. The town itself developed an impressive skyline of ‘tin hats’ (as they were affectionately known) with areas of the town embracing different styles. ‘Lobster Backs’ were popular in Hove and the revolving ‘Hovel’ successful in Kemptown, where tall buildings often blocked intermediate chimneys. ‘The Brighton’ and ‘Vertical Rotary’ appeared almost everywhere. Other types of cowl, including fixed non rotating ones, were installed to satisfy particular needs around the town - the ‘Bent-T’, ‘Drumheads’, ‘Cheeseman’s Cowl’ and ‘Dr Arnaud’s Head’ were all part of the Brighton skyline at that time.

Well into the 1950s, one of the most efficient of all traditional cowls was still being produced in Europe and the Americas. ‘The Archimedean’, with its rotating bladed head-turning an archimedean screw in the shaft, had the ability to quickly and efficiently remove large quantities of air containing floating substances. It was much used in cotton mills and similar large dusty factories and was the last survivor of the original crafted cowls of the Victorian age.

The ‘Colt cowl’, based on a 19th century original, then displaced many of these traditional cowls, and today commercial internet sites advertise it at around £70 but it is a poor relation to the crafted cowls of the Victorian age. Other cowls, such as the cheap and simple ‘Rain Top’ advertised at £20, are still being bought and installed on homes. The more successful ‘Aspiromatic’ is a 20-bladed rotating steel globe, that spins on many chimneys in the UK and Europe and is similar to the original Archimedean. Products called Aspiromatics are still sold, but how they compare to those originals still seen on houses in Brighton is unclear. The original Aspiromatics were magnificent works of craftsmanship and engineering, having one of the highest rates of smoke extraction of any cowl.

[edit] Smoke to ventilation

The increasing severity of air quality issues in many major cities and the great smog of 1952, induced by both weather and pollution, where an anticyclone settled over London, a high-pressure weather system that caused an inversion whereby cold air was trapped below warm air higher up and emissions of factories and domestic fires could not be released into the atmosphere and remained trapped near ground level. It was one of the worst pollution-based fogs causing thousands of deaths and by the middle of the century parliamentary legislation (the Clean Air Acts of 1956 and 1968) outlawed the burning of coal, and even offered grants to switch to different heating sources, such as oil, natural gas, and electricity. As a result, the sale of wind cowls reduced dramatically.

Today many large towns and cities, still have smoke bans and so the demand for cowls is nothing like that of Victorian times. In most cases, cowls are fixed and used at wall penetrations and boiler flues to allow gases and heat to exit. Rotating cowls may in some cases still be used in situations where air or fumes need to be gradually extracted from an internal space, however, increasingly this might be mechanically driven rather than naturally driven.

In some cases, natural ventilation strategies for buildings may also have high-level vents near glazed areas to raise temperatures higher up and make increased use of the stack effect. As the air gets warmer it becomes less dense and so more buoyant with a tendency to rise. This effect can be used to naturally ventilate buildings. Cooler outside air is drawn into buildings at a lower level, it is warmed by sources of heat within the building (such as people, equipment, heating and solar gain), then rises through the building to vent out at a higher level.

The beauty of the rotating wind cowl however is that it harnessed the cause of a problem for its solution. In so far as wind caused the down draught in a chimney, making the interior hazardous, the cowl intervenes between the open chimney, the smoke, and the exterior wind. The design relies on the wind and the heat of the fire to rotate the cowl and dissipate the smoke away while preventing that same wind from entering and causing a down draught. The cowl has the characteristic of adaptability in that, as an ‘add-on’, it can be fitted to any house with a chimney. Though different types and sizes of cowl are selected for different conditions and requirements, it has the qualities of universality, standardisation and decorative interest. In an architectural sense cowls may also be as distinctive design features that help to animate a quite often bland and static roof scape.

[edit] Ventilation wind cowls

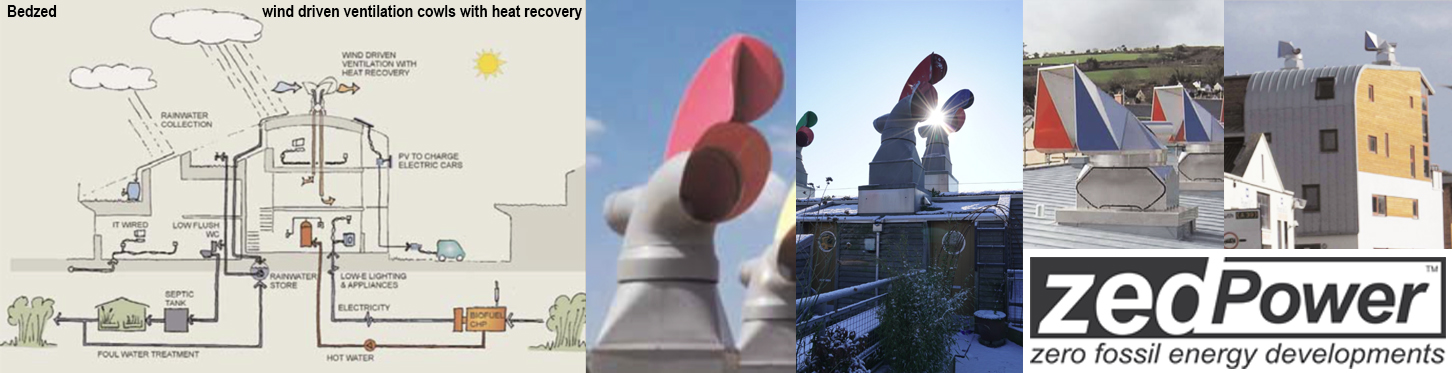

One very modern interpretation and adaptation of the traditional wind cowl was invented by Bill Dunster OBE, the Architect of the UK's first eco-village, located in Wallington, South London. Beddington Zero (fossil) Energy Development (BedZed) is a multi-award-winning development initiated by Bio-Regional, developed by the Peabody Trust in partnership with Bio-Regional Development Group, and designed by Bill Dunster Architects (now Zedfactory) with Arup.

BedZed comprises 82 properties, community facilities, and a visitor centre and was one of the earliest pioneer projects built to address the environmental impacts of construction. It showcases solutions through various sustainability features, in particular, super-insulation, airtightness, heat recovery, and sun-spaces as well as local material sourcing, energy production and wastewater treatment, and re-purposed an area of contaminated land. It was completed in 2002.

One of its key and most recognisable features is the brightly coloured rotating heat exchange ventilation wind cowl.As part of the energy efficiency strategy, it uses a wind-driven natural ventilation system where outgoing stale air preheats incoming fresh air through a heat exchanger located on wind cowls, found on the roofs. The wind cowls can rotate therefore harnessing even very weak breezes. This system allows the air ventilation to be controlled so that a clean internal environment is achieved through associated fabric design of super insulation and high levels of air tightness.

The Dunster cowl has been tested and said to achieve around 70% heat recovery rates, without electrically driven fans. The cowls have been used on a number of buildings designed by the practice, with slight variations in shape, size, style and efficiency.

For more information please visit the companies website by clicking on the images or external link. Images are copyright of Duan Fu from Zedpower and provided here gratefully with permission.

Grateful thanks also to John Redfern for sharing his passion and enthusiasm for wind cowls, may he rest in peace. Thankyou to Bill Dunster and the team at Zedfactory for a solid practical working education into all aspects of environmental design during the short time I was lucky enough to be part if the practice.

[edit] External Links

https://www.zed-power.com/contact

[edit] Related articles on Designing Buildings

- Computational fluid dynamics.

- Cross ventilation.

- Dynamic thermal modelling of closed-loop geothermal heat pump systems.

- Energy targets.

- Face velocity.

- Natural ventilation.

- Passive building design.

- Secondary ventilation stacks in tall buildings.

- Single-sided ventilation.

- Solar chimney.

- Thermal comfort.

- Types of ventilation.

- U-values.

- Natural ventilation.

- Ventilation.

- Warm roof.

- Windcatcher.

Featured articles and news

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.