Temporary demountable structures

Contents |

[edit] Introduction

This article centres on the supply, procurement, design and use of large TV/video screens in outdoor situations. The rapid development of large screen technology has resulted in the common use of these screens. The intent of this article is to examine their use from a structural safety perspective.

[edit] Screen assembly

Screens are assembled from a number of modules. These have advanced over the years, becoming more lightweight (reducing from around 300 kg/m2 to 100-50 kg/m2 over time).

The modules (usually approximately 1.2 x 1.2 m) are assembled into a screen by:

- Inter-module connections.

- A top track beam.

- (Sometimes) a bottom beam.

The modules may be top hung, or stacked from the bottom.

[edit] Modules

Modules are usually pressed steel boxes (although new products are becoming available) some 150-200 mm deep and contain the screen on the front face and the electronics within the depth of the box.

Some module constructions include ‘handles’ on the rear face that can be used to attach restraint members, harness clips, or used as foot/hand holds. Other modules have less facility for this wide range of needs. One company has developed a separate fabricated item which is bolted onto the back of a unit, providing both physical connectivity (vertical surfaces between adjacent units), and the other attributes mentioned.

The adequacy of the inter-module connections (see below) is determined in part by the robustness of the surrounding module framework. Some of these are of relatively light pressed metal construction and may not resist distortion under load. Others are of more robust construction.

[edit] Inter-module connections

The inter-module connections vary in type and apparent adequacy.

Between units (horizontal module surfaces):

- Pinned connections, but of an insubstantial size.

- Over-centre catches.

- Substantial pin/eye connections.

Between units (vertical module surfaces):

- Over-centre catches.

- Coffin catches.

The connections giving vertical connection (via module horizontal surfaces) vary in robustness and in the provision of a visual sign that they are properly ‘locked in place’. Substantial pin/eye connections appear to be the best. Some units using over-centre catches do not have any safety device in addition to the catches.

The connections giving horizontal support (via module vertical surfaces) are perhaps less important from a structural perspective but also vary in their adequacy.

[edit] Support of the screen assembly

The screen is usually completed by a top beam, sometimes supplemented by a number of spreader beams, and transfer tracks, depending upon need. The support itself is via chains passing through motorised hoists; these allow the screen to be raised and lowered.

The manner in which it is connected to the supporting framework elsewhere is relevant to the behaviour of the screen itself under lateral load, and the manner in which it imparts this load to the supporting structure.

A screen supported, restrained and tethered along its top and bottom edges will bend in one (vertical) plane under the action of wind. The connections between vertical surfaces of modules will only be subjected to nominal load. If however, additional substantial tethering is provided on the vertical edges of the screen, then it may act as a ‘dish’ and will bend in two planes, thus introducing greater forces into the connections between vertical surfaces of adjacent modules. However, this is more of a serviceability issue than one of safety, in respect of the screen assembly providing the orthogonal fixings (between horizontal surfaces) are adequate.

[edit] Loadings

The screen assembly is subjected to the following loads:

- Self weight.

- Lateral wind loads (if outdoors).

The self weight is taken by the unit above (via the module connections) and thus into the top beam, or by direct transfer (stacking) to the bottom beam.

Lateral loads from wind introduce a number of issues, viz:

- The need for clear magnitude and definition of the safe design wind force (gust, mean, maximum) and its measurement by those on site.

- The ability of the connections to resist a combination of lateral and vertical loads.

- Lateral movement of the screen which can induce eccentricity (and hence P/Δ effects), and dynamic forces into the support framework.

- The effect upon the screen external support structure.

It is usual practice for the wind sped to be determined via local wind forecasts, requested from the Meteorological Office, or from site based anemometers. It is obviously essential that the data is understood in both cases, and that action/trigger levels are set such that they incorporate sufficient margin against error and time for implementation.

[edit] Screen capacity

It is apparent, from discussions with a number of people, that establishing the safe design loads of the screen (in relation to the connection capacities) is not straightforward as information is often not supplied by the manufacturers, many of whom are from outside the UK (although within the EU). For older modules, the manufacturer may no longer be in business.

The expressed view is that transfer of relevant data to new owners of (second hand) screens rarely occurs.

There appears to be a strong belief that although the vertical load connections may have been tested for dead load, no allowance was made for the effect of lateral load effects which could cause prying forces.

[edit] Design

In so far as the screen is designed, the organisation responsible is usually different from the designer of the support framework.

[edit] Screen support framework

In order for the screen support framework to be designed safely, the designer of the framework must be provided with clear data in respect of the screen including the weight, the assumed (and permitted) means of attachment for resisting both vertical and lateral load, and the design wind speed (making it clear whether this is gust or mean, and over what period).

If the screen is able to swing, or ‘dish’ under the action of wind, thus introducing eccentricity of load in the vertical plane of the support framework, then this must be allowed for.

There will be other considerations, for example whether banners or advertising hoarding will be placed around the framework or added to its wind area, thus increasing the lateral force on the structure.

It is common practice for the screen to be lowered to the ground if the wind speed exceeds a pre-determined value, thus avoiding the need to design for all eventualities. In this situation:

- The stability of the support structure may be adversely affected as the resultant dead weight will be significantly reduced once the screen ‘sits on the ground’, whereas the exposed wind area may still be largely present. A horizontal load effect may also be introduced if the screen swings out of the vertical, introducing a horizontal component of load.

- The practicalities of releasing safety lines, in terms of time and safe working at height in windy conditions, must be considered.

- The trigger level must be sufficiently lower than the critical level, in order that site variances do not absorb any margins of safety.

The behaviour of the support structure can also be adversely affected if the screen is attached in order to reduce swinging movement, when the forces arising from this arrangement are not anticipated.

Support structures need to be checked for stability during erection and dismantling, when, in the absence of the stabilising weight of the screen they may be vulnerable to lateral loads, as noted above. The purpose of any ballasting needs to be fully understood and documented.

Support structures created from proprietary sections (often lattice frames) should be carefully assessed to ensure that they are appropriate for the particular circumstances proposed, and that the joints are properly designed for all loading combinations.

[edit] Truck mounted screens

Some screens are mounted on purpose made artic-trucks. These require out-riggers for stability. It has been reported that some of these are of dubious sufficiency with the suppliers unable to substantiate the resistance to overturning.

[edit] Overall responsibility

It is important that one (competent) person has responsibility for the structural integrity of the structure as a whole, i.e. screen and support framework. Our subjective conclusion is that this does not always occur.

[edit] Procurement issues

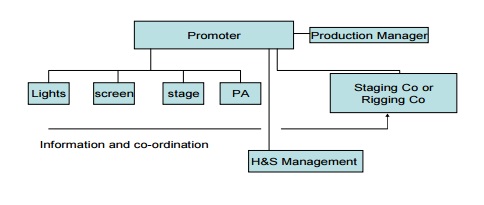

The most common form of procurement appears to be as illustrated below:

This procurement model relies upon close liaison and information transfer between the various contractors, driven by the ‘client’ and contractual obligation.

Staging companies generally have wider experience of erecting and organising than rigging companies which tend to have their experience in this single activity.

The reality appears to be that formal contracts between the promoter and contractor contain little in the way of requirements for information transfer, liaison, and inter-face responsibilities. The ‘client’ takes a back seat in this respect in the knowledge that others know what to do, i.e. in most cases ‘custom and practice’ produce the required result. There is a strong ‘show-biz’ tradition of achieving a result and meeting deadlines.

Responsibility for hanging the screen may be given to the Staging/Rigging Co. or may be left with the screen supplier.

[edit] Legal obligations

The law requires competent organisations to be utilised. The form of procurement illustrated places significant (legal) responsibility on the promoter in this respect and hence this organisation also needs to be competent and have access to competent advice. It is apparent that not all organisations meet this criteria, and selection of contractors is sometimes based on ‘lowest cost’ or ‘quickest response time’ alone.

Most events involve significant financial outlay, and there is as a result considerable pressure ‘for the show to go on’. The adverse publicity arising from a postponement would be detrimental. Hence it can be a difficult balance between satisfying the desire to deliver the event, and the need for adequate safeguard against a potentially unsafe structure.

The ‘competent person’ who is charged with making a decision in the event of a concern over issues with structural safety implications, (rising wind for example) must be capable of doing so without fear or favour. A competent person in this situation must also have ‘structural engineering competence’ or be able to call on those who have, in order to make the appropriate decision, unless (s)he is following a set of prescriptive rules in the management plan.

It is a high risk strategy to assume that someone who is not qualified and experienced in this field, is capable of appreciating all the structural effects including dynamic loads, induced eccentricity, live/dead load ratios and the like. Such an approach is also likely to be at variance with the law.

[edit] Management styles

[edit] Identification and data

Any piece of equipment which is defined as a ‘lifting device’ including all fixings and attachments, must be supplied, marked and tested in accordance with LOLER. Items which are hired-in must arrive with the appropriate certification. It is understood that not all components are marked as they should be, specifically if they originate from overseas.

For those elements which may not fall within the scope of LOLER, but which are nonetheless critical to a safe design, e.g. the inter-module connections, data is required to allow those using the element to be satisfied that it is safe. The inter-module connections fall within the compass of s6 of HASWA which requires adequate data to be supplied, in order that when used, the screen will be safe; notwithstanding, it appears that this data is often not available.

[edit] Design

It appears that there are often shortfalls in:

- Information flow between designers.

- Checking of designs.

- Establishing a single point of responsibility.

Although there may be different opinions as to whether these works fall within the scope of CDM, designers do need nonetheless to comply with the Management of Health and Safety at Work Regulations which both explicitly (first point above) and implicitly (second and third points above) require adequacy on these points (in addition to general duty of care provisions).

[edit] Conclusions

The IStructE expressed concern at the adequacy of inter-module fixings. Although no-one met had witnessed a failure of these fixings, there is a significant problem in that the design criteria are not generally known, and the modules usually arrive without any explanatory data. This is contrary to statutory requirements regarding the provision of adequate information. Designs cannot be ‘signed-off’ as adequate if this data is unknown.

[edit] Generally

On a wider front, current ‘event’ structures are often of a sophisticated form, with safety-critical aspects (e.g. lightweight with large wind area). They require persons of suitable competency to design, construct, use and dismantle them; and to manage the overall process. It is not certain that this always occurs despite the guidance available.

The procurement process is critical to ensuring adequate safety. Evidence suggests that this is not always appreciated by those involved. In particular:

- Design is often fragmented to the detriment of safety.

- Design data (input and output) sometimes lacks clarity.

- Design sometimes lacks a single point of responsibility.

- Emergency procedures do not always pay sufficient attention to practical implementation and the consequence of error in the measurement of wind speed.

- Procurement is sometimes made (specifically in the public sector) by ‘procurers’ or ‘procurement departments’ which do not have the knowledge and experience of these events to make competent judgements and which are under pressure to obtain the best commercial result, viewed in isolation from other aspects of a bid.

- Contractual arrangements sometimes lack written clarity.

The means of procurement and control have not kept pace with the sophistication and complexity of the structures now being used.

Although the IStructE guide generally covers all the requisite issues, it does not perhaps give as much emphasis as it could to actual procurement scenarios.

[edit] Recommendations

[edit] Inter-module fixings

Screens using these ‘inter-module’ fixings should not be used without sufficient data being provided to designers and contractors on their adequacy in the expected conditions of use.

Ideally, fixings should be designed in such that way that there is a clear visual indicator that they are ‘engaged’. The independent erection check should include a specific check on these fixings.

[edit] Generally

There is a need for the outdoor entertainment industry representative organisations to take an active co-operative role in promoting good practice, in relation to:

- The people involved, i.e. their established competence for the role undertaken, judged against recognised benchmarks.

- The processes utilised, e.g. design, procurement, management.

- The products used, specifically the sufficiency of data.

The definition of ‘competency’ should be defined more clearly, i.e. in terms of corporate competency of the organisation employed and the competency of the individuals involved. The approach utilised in the CDM Regulations 2007 would be a good model to adopt in this respect (Management of health and safety in construction L144 HSE Books. Appendix 4).

It is considered that all structures of this type should be:

- Designed by a competent structural engineer,

- Checked and reviewed by a competent chartered structural engineer,

and have one competent structural engineer (who may be the designer) who is responsible for the overall structural stability and robustness, regardless of contractual divisions.

The principles of the CDM Regulations 2007 should be embedded in the design, procurement and construction of this type of structure, i.e. competency, co-operation, co-ordination, information flow, adequate time and resource.

The questionnaire should be used by designers and others as an aide mémoire to good procurement.

[edit] Questionnaire

Issued to the National Outdoor Events Association and the National Events Forum in March 2007, and to PLASA and PSA in October 2007.

LARGE TV/VIDEO SCREENS USED AT OUTDOOR PUBLIC EVENTS

The use of these screens at public events, and specifically those that are outdoors, has increased significantly in recent years. They are frequently large and heavy assemblies. They are often positioned over, or close, to performers or the public. The questions posed are intended to help SCOSS understand the control process.

QUESTION LIST

| 1 | Do those who assemble individual modular screen units into overall assemblies provide critical design data to allow those using them to check that they are suited to the specific circumstances of use. |

Typical data would include: 1- assumed support conditions and lifting points during erection and use. 2-safe wind loads (specifying whether gust, peak, average etc) 3- overall weights 4- certification for lifting (in accordance with LOLER) |

| 2 | Does this data (noted under 1) cover the connections between the modular units as well as the overall assembly. Note: if modular units are purchased as individual units, with provision for connection between these units, are the accompanying data sufficient to allow overall design to be achieved. | For some screen assemblies the connections between modular units is crucial to the strength of the whole assembly; they have to resist lateral loads (wind) and vertical loads (self weight). If the units are top hung, the inter-unit connection becomes increasingly loaded as one works towards the top of the assembly. |

| 3 | Do the procurers of these screens have the experience and knowledge (competence) to ensure that screens bought or hired have been adequately designed as noted above. | |

| 4 |

For typical events, are responsibilities clear: 1-contractually |

The responsibilities may be different between the two routes, e.g. Section 3 of HASWA may have a consequence quite different from the intended contractual allocation of responsibility. |

| 5 | Does the key design data follow the product adequately, if it is sold-on. | If these screens become ‘second-hand’ products, it is obviously essential that key safety information is transferred with the change in ownership. |

| 6 |

If design of the screen itself is undertaken by a different party to that designing the support frame, is there: i) Written confirmation of respective responsibilities? ii) Written transfer of relevant information iii) One person with overall responsibility? |

|

| 7 | Do management plans outline practical measures to be taken in the event of excessive wind? |

i.e. measures that can be put in hand, in time and safely. i) is any error in the measurement of wind speed likely to counter any safety factor in the design (a 15% error would result in a 32% increase in wind load)? ii) If security lines have to be released by working at height, would this satisfy the Work at Height Regs?) |

| 8 | Are those companies erecting screens and support frames appointed having due regard to competency, or is the appointment based on lowest cost alone? | Those employing others have a duty to ensure the engaged party is competent to do the job. For advice on corporate competency see Annex 4 of the ACoP to the Construction (Design and Management) Regulations2007. The Annex applies regardless of whether the regulations are applicable. |

| 9 |

Do the persons who decide whether to proceed with an event (say in the presence of adverse weather) have: i) the formal competence to assess structural engineering issues ii) call on those who do iii) proceed under their own judgement |

|

| 10 | Are TV screen structures inspected by a qualified structural engineer prior to use? |

This topic paper was issued by SCOSS in Feb 2008. You can see the original paper here.

[edit] Related articles on Designing Buildings

- Architecture of concert stage designs.

- Bandstand.

- Building regulations exemption for temporary buildings.

- Fixtures in buildings.

- Gazebo.

- Health and safety.

- HORSA hut.

- Kiosk.

- Licensing.

- Lifting Operations and Lifting Equipment Regulations (LOLER).

- Live event production.

- Pavilion.

- Permitted development.

- Structure relocation.

- Temporary.

- Temporary building.

- Temporary use.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.