Process Redesign: A Comprehensive Guide for Quality Professionals in Business and Engineering

[edit] Introduction

The engineering of a process is the design of the steps to realise a product/service and the release of the relevant procedures and instructions. The construction industry is featured by its complex projects, the fragmentation of stakeholders, and the pressure to respect clients' requirements while delivering on time and within budget. Hence, upon implementation or over time, the designed processes may prove to be inefficient. Process redesign can be a valid path to transform the work processes to achieve the initial goals.

This article aims to provide a comprehensive understanding of process redesign, tailored for quality professionals in the construction industry. It presents the fundamental principles, methodologies, and practical applications of process redesign, supported by academic research and real-world examples. The role quality professionals will be proven crucial in driving successful transformation.

For the scope for this article, we present the process redesign in its main configuration, giving our best advice how to take the most and proposing solutions that can be implemented in the construction industry.

[edit] Understanding Process Redesign:

The process redesign is mainly intended as Business Process Redesign (BPR), developed for industries other than the construction sector. However, conscious of the peculiarity of the construction market (customer focused, project based, process oriented, performance improved and value generated), researchers developed a more specific Construction Process Redesign (CPR) (Cham, Fan, Yu, 1999). The focus remains on the BPR, as supported by wider research and because the CPR advises for a flexible approach, which is underpinned by this article.

BPR was defined by Davenport and Short in 1990 as the “analysis and design of workflows and processes within and between organisations” (Earl, 1994). The origins are dated to the activities of companies like Xerox, Ford, IBM, Cigna, Texas Instruments, who were transforming their way of organising their business in the 1980s. The changes were mainly around three areas:

- Redesign or reengineering their key business activities.

- Applying the concept of “process”, so inputs-outputs; something common nowadays, but not so at the time.

- Exploiting information technology to redesign the processes.

Process redesign was described by Hammer and Champy (1993) not only as incremental improvement but as a fundamental rethinking and radical redesign of business processes to achieve substantial positive impact in cost, quality, service, and speed. In the context of construction, this mandates to examine workflows to spot all the inefficiencies and implement appropriate change. Specifically:

- Redefining procurement strategies.

- Optimising material flow and logistics.

- Implementing advanced technologies for project management and collaboration.

- Standardising quality control procedures.

- Enhancing safety protocols.

As mentioned by Reijers&Mansar (2005), a “BPR initiative is commonly seen as a twofold challenge:

- a technical challenge, which is due to the difficulty of developing a process design that is a radical improvement of the current design,

- a socio-cultural challenge, resulting from the severe organisational effects on the involved people, which may lead them to react against those changes.”

Furthermore, the project management of a BPR is a challenge per se (Reijers&Mansar, 2005).

Finally, “the fundamental challenge is to come up with a new process design that is one or more ways superior to the existing plan” (Mansar&Reijers, 2005).

[edit] Why is Process Redesign Crucial in Construction?

The nature of the construction industry poses various challenges:

- Fragmented Processes: there are numerous stakeholders, each with their own processes and systems. This fragmentation can lead to communication breakdowns, delays, and errors.

- Waste and Inefficiency: Traditional construction practices often involve significant waste of materials, time, and resources. Typical topics are:

- Overproduction: Producing materials or components before they are needed.

- Waiting: Delays caused by lack of materials, equipment, or information.

- Transportation: Unnecessary movement of materials or equipment.

- Inventory: Excess materials stored on site.

- Motion: Unnecessary movement of workers.

- Defects: Rework and repairs caused by errors or omissions.

- Overprocessing: Performing unnecessary tasks.

- Non-utilised talent: Not using the full skill set of the workers. Process redesign can help identify and eliminate these forms of waste, leading to significant cost savings and improved productivity.

- The change out of personnel during process execution with a potential for a lack of training on how the process works in operation.

- Quality Issues: Defects and rework are common in construction, leading to increased costs and delays.

- Safety Concerns: As any other industry, also Construction environment requires continuous focus on safety.

- Technological Integration: The adoption of new technologies, such as Building Information Modelling (BIM) and digital project management tools, necessitates process redesign to maximise their benefits.

- Sustainability: Increasing emphasis on sustainable construction practices requires rethinking traditional processes to minimise environmental impact.

Process redesign can help for all above-mentioned challenges. As examples:

- Enhancing resilience of the organisation and anticipating impactful events, for which mitigation plan must be prepared in advance.

- Identifying and eliminating inefficiencies.

- Improving quality by standardising processes and implementing robust quality control measures.

- Improving safety by implementing safer work practices, assessments, promoting culture of safety, and reducing risks.

[edit] Principles of Process Redesign:

Effective process redesign is guided by several key principles:

- Customer Focus: Processes should be designed to meet the needs of the end customer, whether it's the building owner, the occupants, or the community. In construction, this means understanding client requirements and delivering projects that meet their expectations.

- Process Thinking: Process redesign requires a shift from a functional view to a process-oriented perspective. This involves understanding how different activities contribute to the overall project objectives.

- Radical Change: Process redesign ensures continuous improvement, but its implementation is not about incremental improvements; it's about making fundamental changes to achieve significant performance gains.

- Information Technology Enablement: Technology plays a crucial role in enabling process redesign. BIM, cloud-based collaboration tools, and mobile applications can streamline workflows and improve communication. Artificial intelligence can support, as well, even though its use is too recent to be supported by scientific studies and offer reliable support.

- Empowerment: Employees should be an active component of the BPR up to be empowered to make decisions that improve performance.

- Continuous Improvement: Process redesign is not a one-time event; it's an ongoing process of monitoring, evaluating, and refining processes. As written before, each change is radical, not a lifetime event.

[edit] Steps in Process Redesign:

A typical process redesign project involves the following steps:

Define the Scope: Clearly define the boundaries of the process to be redesigned. Define the objectives to be satisfied. Identify the key stakeholders and their requirements.

Analyse the Current Process: Document the existing process and decompose it into its parts. A complex process may first be divided into sub-processes; then, each sub-process can be listed as a sequence of individual tasks. Flowcharts, process maps, or BPMN diagrams can be used. Identify bottlenecks, inefficiencies, and areas for improvement.

Design the New Process: Develop a new process that addresses the identified issues and meets the project objectives. Consider the use of technology, automation, and best practices. While designing the new process, it is crucial to assess the potential impact that the change may have upon other processes, which the process being redesigned may interface or interact with.

Implement the New Process: Develop a detailed implementation plan, including training, communication, and change management. The new process should be first tested in a controlled environment before full-scale implementation.

Monitor and Evaluate: The implementation shall be monitored to verify the performance of the new process and the gaps, if any, to be filled. The use of KPIs is strongly advised in this phase.

Continuous Improvement: Once established, the new process shall become part of the continuous improvement efforts, benefiting from a culture of learning that includes lessons learned, regular reviews and feedback mechanisms.

[edit] How to select the best practice for the most common cases: the BPR Framework

After defining the BPR steps and before mentioning which tools and methodologies can be used to support the BPR effort, it is important to identify how to select the most appropriate best practice for our case.

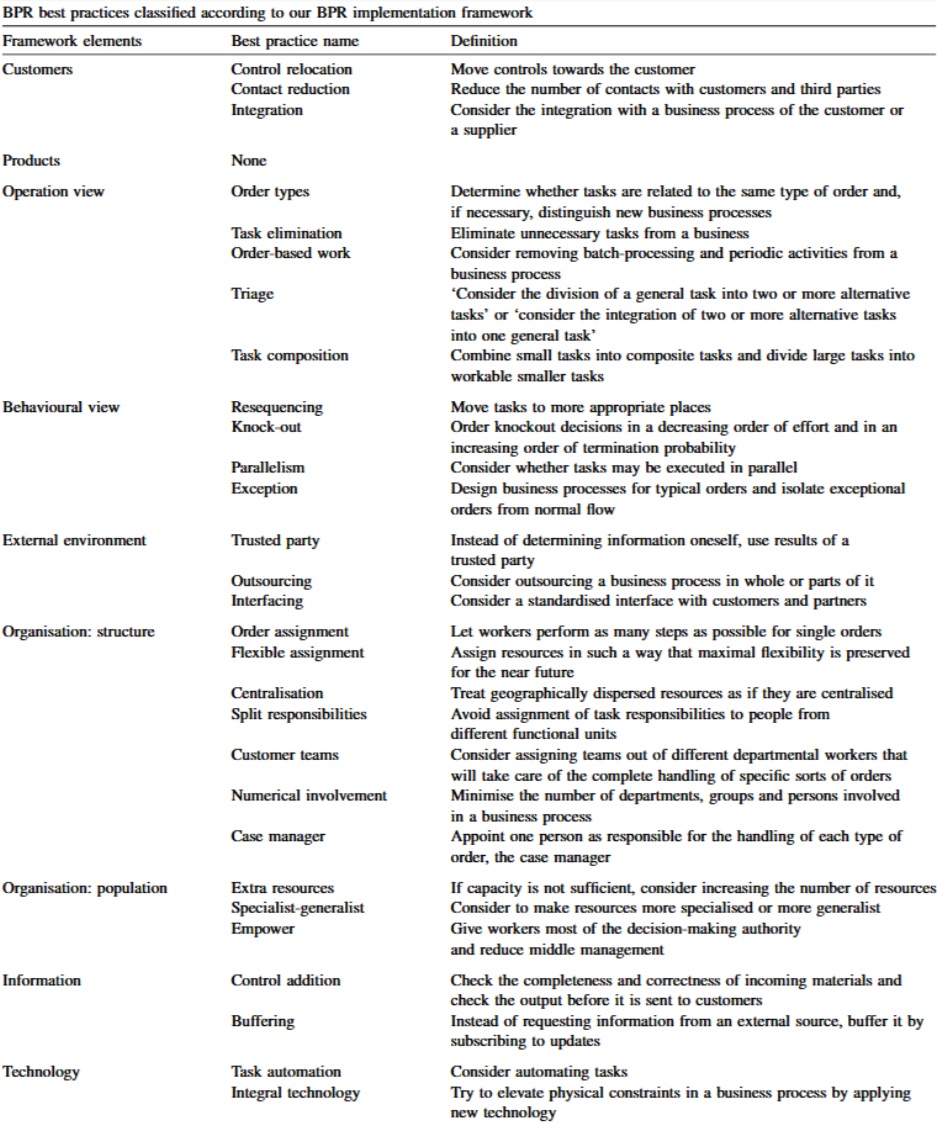

Reijers&Mansar (2005) proposed a framework to lead the process redesign. Specifically, the scope is “to help the designer in selecting the proper best practices” for the BPR, collected over 20 years application in various areas (business planning, healthcare, manufacturing, and software development). The best practices are listed in the table below.

The choice is facilitated by six elements, integral part of the framework:

- the internal or external customers of the business process;

- the products (or services) generated by the business process;

- the business process with two views:

- the operation view: how is a business process implemented? (number of tasks in a job, relative size of tasks, nature of tasks, degree of customisation), and

- the behaviour view: when is a business process executed? (sequencing of tasks, task consolidation, scheduling of jobs, etc.);

- the participants in the business process considering:

- the organisation structure (elements: roles, users, groups, departments, etc.), and

- the organisation population (individuals: agents which can have tasks assigned for execution and relationships between them);

- the information the business process uses or creates;

- the technology the business process uses, and finally;

- the external environment other than the customers.

The framework was not developed for the construction industry and is presented in this article for completeness. However, some of the practices listed above can be applied even in the construction world.

[edit] Methodologies for Process Redesign:

Once it is defined what we want to achieve, the target may be reached by several methodologies:

Lean Construction: Lean principles, derived from the Toyota Production System, focus on eliminating waste and maximising value. Lean construction tools, such as value stream mapping and 5S (refer to other articles from the ConSIG in DesignBuildingWiki), can be used to identify and eliminate inefficiencies in construction processes.

Example: Implementing a "Last Planner System" to improve workflow reliability and reduce schedule variability.

Six Sigma: Six Sigma is a data-driven methodology that aims to reduce variation and defects in processes. DMAIC (Define, Measure, Analyse, Improve, Control) is a key tool used in Six Sigma projects.

Example: Using statistical process control to monitor concrete strength and reduce the number of defective pours.

Business Process Modelling and Notation (BPMN): BPMN is a standardised graphical notation for representing business processes. It allows for clear communication and analysis of process flows.

Example: Using BPMN to model the procurement process and identify bottlenecks.

Building Information Modelling (BIM): BIM is a digital representation of physical and functional characteristics of a facility. It enables collaboration, coordination, and clash detection, leading to improved project outcomes.

Example: Using BIM to coordinate mechanical, electrical, and plumbing installations, reducing rework and delays.

Agile Project Management: Agile methodologies, such as Scrum and Kanban, emphasise iterative development, flexibility, and collaboration. They can be applied to construction projects to improve responsiveness to changing requirements.

Example: Using daily stand-up meetings to improve communication and coordination on site.

[edit] Practical Applications in Construction:

Here are some additional examples of how process redesign can be applied in different areas of construction:

Procurement: Streamlining the procurement process by implementing e-procurement systems, standardising contracts, and improving supplier relationships.

Material Management: Reducing material waste by implementing just-in-time delivery, using modular construction, and improving inventory control.

Site Logistics: Optimising site layout and material flow to improve efficiency and safety.

Quality Control: Implementing automated quality control systems, using BIM for clash detection, and improving communication between stakeholders.

Safety Management: Implementing safety training programs, conducting risk assessments, and using technology to monitor safety performance.

Project Management: Implementing agile project management methodologies, using BIM for project coordination, and improving communication between stakeholders.

Handover Process: Implementing a digital handover process to transfer project information efficiently.

Rework Reduction: Using root cause analysis to reduce the amount of rework needed on projects. Using better communication to reduce errors.

[edit] Challenges and Considerations:

Before starting with BPR, it is critical to consider some factors linked to its challenging nature:

- Resistance to Change: Employees may resist changes to familiar processes. Effective communication, training, and change management are essential.

- Complexity: Break down complexity into manageable components.

- Data Availability: Data is essential for process analysis and improvement. It must be accurate and reliable throughout the redesign.

- Stakeholder Engagement: Engage all stakeholders in the process redesign effort, as their input and support are valid contributors to success.

- Technology Implementation: Selecting and implementing the right technology is critical for process redesign. Ensure that the technology is compatible with existing systems and meets the project requirements.

- Training: Workers must be trained on the new processes.

[edit] The Role of Quality Professionals:

Quality professionals play a crucial role in process redesign in construction. They can:

- Lead Process Analysis: Use quality tools and techniques to analyse existing processes and identify areas for improvement.

- Facilitate Process Redesign Workshops: Bring together stakeholders to develop new process designs.

- Implement Quality Control Measures: Ensure that the new processes are implemented effectively and that quality standards are met.

- Monitor Process Performance: Collect data on key performance indicators and use them to track progress.

- Promote Continuous Improvement: Foster a culture of continuous improvement by encouraging feedback and implementing changes based on data.

[edit] Conclusion:

Process redesign is a powerful tool for construction professionals to improve efficiency, quality, and safety. By applying the principles and methodologies discussed in this article, construction companies can achieve significant performance gains and stay competitive in a dynamic market. Quality professionals are instrumental in leading and supporting process redesign initiatives, ensuring that projects are delivered on time, within budget, and to the highest standards. The research on CPR is not as wide as for BPR. However, the flexibility recognised by the CPR and the transverse nature of the CPR offer a robust base for continuous improvement.

[edit] References:

- H.A Reijers, S.Liman Mansar (2005). “Best practices in business process redesign: an overview and qualitative evaluation of successful redesign heuristics”. Omega, Volume 33, Issue 4. https://doi.org/10.1016/j.omega.2004.04.012

- Selma Liman Mansar, Hajo.A. Reijers, (2005). “Best practices in business process redesign: validation of a redesign framework”. Computers in Industry, Volume 56, Issue 5, June 2005, Pages 457-471. https://doi.org/10.1016/j.compind.2005.01.001

- Michael J Earl (1994). The new and the old of business process redesign. Journal of Strategic Information Systems 1994 3 (1) 5 –22. 0963-8687/94/010005-18 Butterworth-Heinemann Ltd

- Albert P.C. Chan, Linda C.N. Fan and Ann T.W. Yu (1998). “Construction process reengineering: a case study”. Logistics Information Management, Volume 12 – Number 6, 467-475. MCB University Press. ISSN 0957-6053

Original article written by Giorgio Mannelli and reviewed by Colin Harley on behalf of the Chartered Quality Institute, Construction Special Interest Group (ConSIG). Article peer reviewed by the ConSIG Thought Leadership Group (former Knowledge Working Group) and accepted for publication by the ConSIG Steering Committee.

--ConSIG CWG 11 Oct 2025 (BST)

[edit] Related articles on Designing Buildings

- Accelerating change: A report by the Strategic Forum for Construction.

- Advanced construction technology.

- Business process reengineering BPR.

- Change management on construction projects.

- Construction manager.

- Information and communications technology in construction.

- Lean construction.

- Reinventing construction: a route to higher productivity.

- Supply chain management in construction.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”