Recycled waste plastic in construction

Contents |

[edit] Waste plastic hierarchy

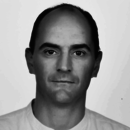

When talking about any recycling, especially recycled plastic, Lansink's ladder, better known as the waste hierarchy or waste management hierarchy, should be taken as a first principle. Firstly to talk of waste, because still on a global scale the majority of plastic becomes waste, it may slowly be talked of as a resource, but currently it is waste first and with correct management as a resource second.

The hierarchy, initially shown as a triangle (perhaps based on Lansink's initial ladder approach), is often also seen inverted, with the widest element, prevention at the top, to reiterate the greater impacts of waste management being through minimising the amount of products or plastics used. This is then followed by investigating the possibilities for re-use or re-purposing, then the now expanding approaches to and methods for recycling, which this article focusses on, followed only then by routes to recovery, most likely energy recovery (with associated emissions and particulates) then finally followed by disposal as the final resort and under an ideal circular economy almost non existent.

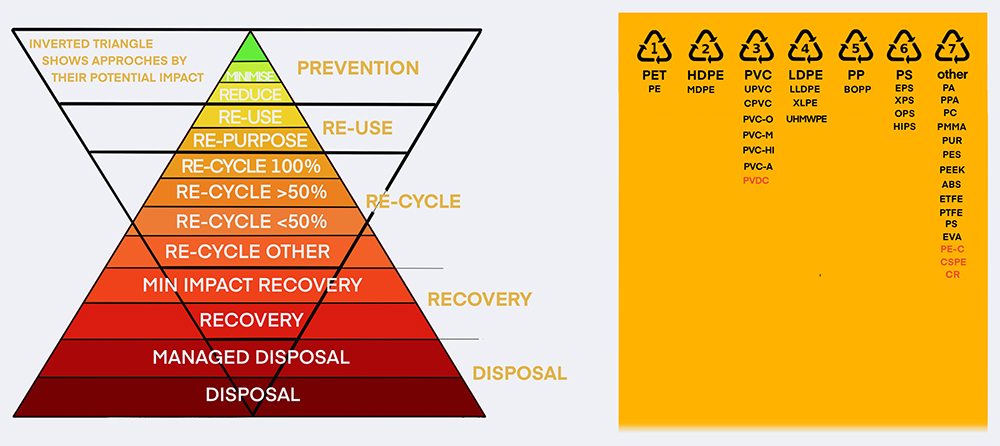

A second hierarchy which is often misinterpreted was developed in the late 1980's by the Society of the Plastics Industry. The Resin Identification Code (RIC) divides plastics into 7 different categories;

- Polyethylene Terephthalate (PET or PETE),

- High-Density Polyethylene

- Polyvinyl Chloride (PVC),

- Low-Density Polyethylene (LDPE),

- Polypropylene / Polypropene (PP),

- Polystyrene (PS) and

- Other.

Under most categories there are a number of different variations, whilst under the number 7 other there are a wide range of products, which in construction increasingly includes composite materials.

As one of the largest producers of plastic globally, China (32%) and the standardisation administration of the People's Republic of China (SAC) has defined a long list of material codes for many different types of plastics in their document GB 16288-2008, this includes numbers 1-6 as per the Resin Identification Code but continues on beyond number 6 up to 140 different types and names of plastics. There is much debate and reporting on health as well as environmental issues surrounding plastic, this includes not only the base plastic product but also the many and varied chemicals used as additives, some of which can impact possibilities for and methods of recycling. Some items list in the graphic are highlighted in red, these plastics have previously been listed as damaging on the International Living Building Institute materials red list, along with other chemicals some of which are used in the plastic production.

This article highlights further why the waste management hierarchy is key when considering recycled plastic in construction. Plastic being a extremely complex but versatile material, is used extensively in the construction industry and over long cycles, as opposed to perhaps more significantly problematic short cycle single use plastics. As an industry there are an increasing number of opportunities for recycled plastic, often only picked up through particular attention to specifications and product selection. Its use nonetheless should be considered in the context of increasing climate and environmental issues, and material understanding.

[edit] Waste plastic agreements

In 2022, on March 2, at the 5th meeting of the UN Environmental Assembly (UNEA) 175 nations agreed on a draft resolution to create an international, legally binding agreement to end plastic pollution by 2024. The draft resolution K2200647 was entitled "End plastic pollution: Towards an international legally binding instrument".

The first session of the Intergovernmental Negotiating Committee (INC), known as INC-1, was held nine months after representatives from 175 countries endorsed the landmark resolution on plastic pollution at the United Nations Environment Assembly. The UN Environment Programme began the process of consulting with stakeholders from November 28 to December 2, with representatives from governments, the private sector and civil society to develop the international legally binding instrument to end plastic pollution, including in the marine environment

The resolution states the treaty can include binding and voluntary approaches to end plastic pollution that address the full lifecycle of plastics. Coalitions of member countries initially put forward three different proposals with varying scopes for the treaty. In the end, the resolution has been set to address the full lifecycle of plastic including production and disposal. It was reported that the resolution would include a reference to concern about chemicals present in plastics, but some delegations including the United States objected to this, resulting in its removal. Instead, the resolution mentions the need to consider the risk posed by plastic pollution to human and environmental health.

In 2021 draft legislation, the Plastic Packaging Tax, was published by the UK Government. On 1 April 2022 the tax came into force, with charges of £200 per tonne for any packaging with less than 30% recycled content. Plastic packaging components containing 30% or more recycled plastic are not chargeable for the tax. However, they still count towards the 10-tonne threshold for packaging manufactured or imported in a 12-month period, and records must still be kept.

For the purposes of the tax, all plastic is assumed to be made using non-recycled (virgin) material, unless there is evidence that recycled material has been used. For the purposes of the tax, plastic means a polymer material to which additives or substances may have been added. Cellulose-based polymers that have not been chemically modified, such as viscose, will not be treated as plastic. Other cellulose-based materials which are chemically modified, such as cellulose acetate, will be considered plastic. Additives include materials such as calcium or dyes. When you assess the amount of plastic in a packaging component, the additives are classed as part of the plastic.

Plastics include polymers which are:

If a plastic packaging component is made from multiple materials but contains more plastic by weight (including additives which form part of the plastic) than any other substance, it will be classed as a plastic packaging component.

In April 2018 WRAP (Waste and Resources Action Programme), together with the Ellen MacArthur Foundation, launched The UK Plastics Pact, which is supported by DEFRA (Department for Food and Rural Affairs) and led by WRAP.

The aims of the UK Plastics Pact are by 2025 to:

- Eliminate problematic or unnecessary single-use packaging through redesign, innovation, or alternative (reuse) delivery models

- Ensure 100% of plastic packaging is reusable, recyclable or compostable

- Effectively recycle or compost 70% of plastic packaging effective

- Maintain a 30% average of recycled content across all plastic packaging

[edit] Waste plastic streams

In simple terms there are in effectively two primary sources or streams of recycled (as well as re-used) plastic that might most commonly be used in the construction industry, their use is normally measured by their recycled content.

- Construction and demolition (C&D). plastic waste from construction is usually made up of off-cuts, over orders and packaging, whilst plastic waste from demolition includes a wide range of building elements including pipes, gutters, window and door frames,

- Household plastic waste from household products unsuitable for re-use in the same sector, bottles, packaging etc

Around one third of waste from construction sites is packaging waste such as timber, cardboard and plastic.

Whilst no plastic tax has as yet been applied specifically to the construction industry, one route to improving domestic waste recycling rates has been that the construction sector acts as ‘sink’ for waste plastics, utilising recycled plastics as raw materials for construction products.

Over a longer term basis if plastic is used in construction projects through necessity, then specifying plastics with ideally 100% recycled content (RC) must be the aim to close loops. Where such products don't exist, the specification of products with decreasing levels of recycled content has to be followed, however (as explained later) there is a point of diminishing impact where recycled content is so low, it might be considered to support the continued manufacture of virgin material, making up the majority of the content.

If the specification of virgin plastic in unavoidable then selecting types of plastic that occur higher rather than lower in the Resin Identification Code (RIC) system, is important, thus facilitating greater possibilities for recycling in the future. The RIC, designed in many ways for householders and now some 40 years old, has significant gaps in helping to better understand plastics and recycling, furthermore the issues between household products and construction products differ significantly as does the range in the type of plastics used in the industry.

[edit] Waste plastic cycles

Of the two types of plastic, thermoplastic and thermosets, it is accepted that the former has greater recycling or re-use potential. Whilst up to 75% of all global plastic that is produced is thermoplastic, and thus recyclable, the reality in 2022 as highlighted by OECD was that "only 9% of plastic waste is recycled (15% is collected for recycling but 40% of that is disposed of as residues). Another 19% is incinerated, 50% ends up in landfill and 22% evades waste management systems and goes into uncontrolled dumpsites, is burned in open pits or ends up in terrestrial or aquatic environments, especially in poorer countries." The impact of these plastics falling out of human-managed cycles and into natural biological cycles in the form of micro-plastics is well documented.

Whilst different sources often give different figures, it is agreed in general that plastic production has continued to increase over the past 30 years, whilst recycling rates have only increased marginally. Again the OECD suggest it has quadrupled over the past 30 years, whilst it doubled from 2000 to 2019 to reach 460 million tonnes, accounting for 3.4% of global greenhouse gas emissions. In turn global plastic waste generation more than doubled from 2000 to 2019 to 353 million tonnes, highlighting that nearly two-thirds of plastic waste comes from plastics with lifetimes of under five years, with 40% coming from packaging, 12% from consumer goods and 11% from clothing and textiles.

[edit] Waste plastic value

In the Forbes article Three Reasons Recycling Is Failing, from May 2022 the author Jeff McMahon talks of underinvestment, under-participation and unchanging laws underpinning the way in particular recycling in the US is failing.The climate and environmental benefits of recycling are not reflected in the economics, or the climate benefits are not being translated to financial cost reductions over longer terms and thus lack the correct levels of investment. The mismatch in the societal benefits, such as reduction of emissions from oil related virgin material, pollution reduction and health costs are not economically linked to the one sector that could change many of the issues, the producers.

The producers are not involved, linked or responsible for the plastic waste that they effectively produce, it is not considered part of their product. He also discusses confusion around how, when, where and what can be recycled and into what with laws and guidance some 30-40 years out of date.

There are many, many different types of plastic in circulation and many other chemical issues associated with the industry such as forever chemical and Bisphenol A (BPA), the field is one of contamination mines. As well as this whilst access to recycling systems globally is very low, in countries where management systems are in place often only plastics that are uncontaminated are likely to be used at the recycling centres. The contamination issue can be both on the consumer side in terms of the preparation or washing of plastic before recycling but also on the producer side in terms of mixes and material expectations. For example clear plastics used for drinks bottles rather than cloudy or lower quality plastics likely to come from recycled plastics, this means that in competition with virgin plastics, waste or recycled plastics often lose based on quality issues.

[edit] Waste plastic content

Where higher end products, such as particular types of packaging do contain recycled content it is often far lower than the marketing impressions might give. For example polyethylene terephthalate or PET, which is number 1 on the RIC scale, is the form of plastic that is globally the most recycled plastic. However, whilst statistic are changing, most new PET bottles produced, generally contain less than 15% of the recycled material, so for each bottle 85% of it is in-fact supporting continuation of the virgin plastic producing industries. The price of virgin plastic is inherently linked to the price of oil and so can vary dramatically, and the circular economy starts to look at recycling more holistically creating greater value in closed loop material streams as opposed to linear streams that include the production of virgin materials.

There are similar stories with Polyvinyl chloride (PVC) and some of its derivations such as uPVC or CPVC, particularly when looking at plastic waste in the construction industry. PVC as a thermoplastic is said to be recyclable up to 15 times, and although specific figures for PVC, which is the third most produced plastic globally are difficult to find, as long ago as 2005 (WWF) around 1% of global PVC was recycled, whilst more recently Recovinyl reported in 2020 up to 18% of PVC used in the UK was recycled. Whilst this might tell a similar story to that of PET bottles where recycled content in effect continues to support the production of virgin PVC through low recycled content products, in 2009 the British Plastics Federation published information of PVC windows, gutters and drainpipes that contain 98-100% recycled PVC. This implies that higher content products are possible and because of the nature of construction closed loop circular economies are becoming more viable. In 2021 a similar story can be seen with with opportunities for recycled content (RC) with some vinyl flooring containing up to 60% PVC RC, soil or waste pipes up to 40% PVC RC and cabling 50% PVC RC.

[edit] Waste plastic quality

In 2021 The Alliance for Sustainable Building Products (ASBP) in their article by Katherine Adams "Recycled plastics in construction – Is it a good thing?" highlighted that the construction sector acts as ‘sink’ for waste plastics, utilising recycled plastics as a raw material for construction products and in doing so helping to improve domestic waste recycling rates. Where household waste may not be suitable for recycling within the household products industry, or at least at low levels of recycled content, contaminated or lower quality plastics can be used by the construction industry, but not without watch points, relating to toxic elements of some of those products.

The ASBP article also points out one significant issue with increasing ease of specifying recycled content in construction, or at least focussing on this as a route to environmental credentials is that it becomes a feedstock for those products meaning there is little incentive to reduce the original plastic products from which they come. As such particularly in Europe the aim must be to look for alternatives and if not to ensure any plastic that is specified remains 100% within a closed loop of use and re-use. This is something that even when achieved can have to deal with other issues such as additives, by example PVC, European Parliament in Strasbourg proposed derogation for the continuous use of recycled PVC containing legacy lead substances.

Most plastics diminish in quality as they are recycled, either through processing or more likely through contamination, and so the potential of their use will relate directly to the quality needed for the next product. Whilst the arguments for avoiding long term cycling of plastic products from virgin products to mixed products with recycled content, then down cycling further to broader products have been made, the issue of existing plastic waste remains. The 80 odd % of plastic already produced, past its useful life continues to act as a pollutant and danger to the environment. In these cases there are some very clear and strong arguments for producing construction products to take these out of an un-managed environment and controlling them in suitable products. This solution for recycled plastic in construction is one that deals with waste rather than looking at recycled content as a long tern feedstock.

--editor

[edit] Related articles on Designing Building

- Glass reinforced plastic GRP.

- Glass fibre reinforced plastic.

- Polycarbonate plastic.

- Plastic cladding.

- Plastic and recycling.

- Plastic coating market.

- Plastic in construction.

- Plastic in concrete.

- Recycled plastic bridges.

- Types of plastic in construction.

- Wood plastic composites market for construction.

[edit] External references

- https://asbp.org.uk/asbp-news/think-piece-recycled-plastics

- https://blog.nationalgeographic.org/2018/04/04/7-things-you-didnt-know-about-plastic-and-recycling/

- https://www.unep.org/plastic-pollution

- https://www.greenspec.co.uk/building-design/red-list-of-banned-toxic-construction-materials/

- https://www.refficiency.org/wp-content/uploads/2020/10/ThePWord2.pdf

- https://www.plasticsforchange.org/blog/category/why-are-plastic-recycling-rate-so-low

- https://www.bpf.co.uk/sustainable_manufacturing/recycling/The_Worlds_First_100_percent_Recycled_PVC_Window.aspx

- https://www.gov.uk/government/statistics/uk-waste-data/uk-statistics-on-waste

- https://www.recyclingtoday.com/news/recovinyl-axion-vinyl-pvc-recycling-uk-ireland/

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Comments

[edit] To make a comment about this article, or to suggest changes, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.