Teeside Collective - carbon capture and storage

[edit] Introduction

Carbon capture and storage (CCS) is an important technology for the future of UK industry as there are limited viable alternatives for industry to decarbonise. This article details plans to clean up Teesside including the financial model for industrial CCS and the funding role government needs to play.

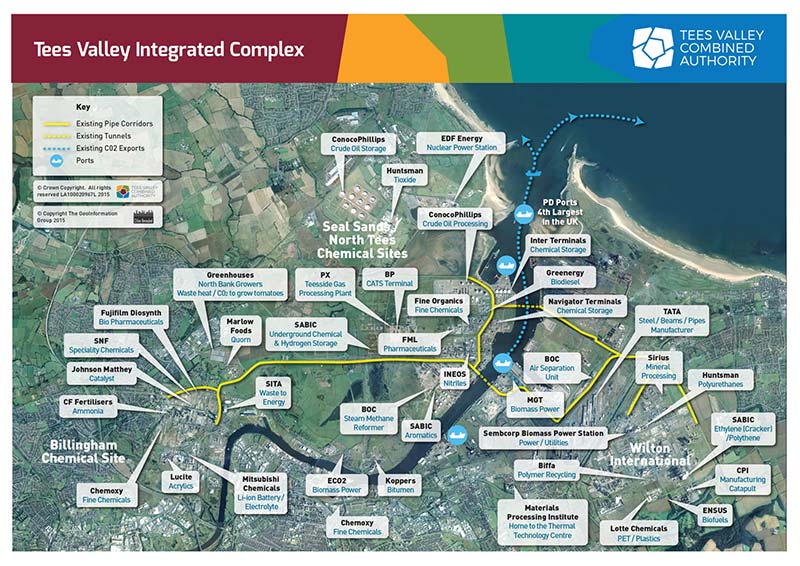

Teesside has one of the highest concentrations of industry in the UK. Located close to North Sea carbon storage sites, a carbon capture and storage (CCS) network has the potential there to be as significant as offshore wind and new nuclear power and accelerate the UK's journey towards a competitive, low carbon economy.

The UK needs projects like Teesside Collective to generate new options to meet its carbon targets cost-effectively and industry needs the project to provide a solution for their carbon emissions while making these UK sites an attractive investment option.

[edit] UK's first commercial scale CCS project

CCS is no longer primarily a technical challenge, it is now a commercial challenge. Implementing a CCS network in Tees Valley – which Teesside Collective's work has shown is technically viable – would represent the UK's first commercial scale CCS project and establish Tees Valley as a pioneer of industrial development.

The project is now ready for government to work with the development team on phase one.

[edit] What is Teesside Collective?

Teesside Collective is a ready-made, cost-effective opportunity for the UK to start removing carbon dioxide emissions from its vital process and chemical industries.

Teesside Collective is a cluster of leading energy-intensive companies working together to build one of Europe's first CCS equipped industrial zones and has the potential to help to retain the UK's industrial base, attract new investment and jobs and meet the UK's climate change targets.

The group is made up of 5 large industrial companies in the region:

- BOC – UK's largest hydrogen plant.

- CF Fertilisers – UK's largest ammonia plant producing fertiliser.

- Lotte Chemical UK – produces PET for 15bn recyclable plastic bottles every year.

- Sembcorp – provides industrial utilities for the UK's largest integrated industrial site and planning for large scale CCGT.

- SABIC – the UK's largest cracker which is upgrading to run on US shale gas.

Teesside Collective is coordinated by Tees Valley Combined Authority and backed by the North East of England Process Industry Cluster. More industrial companies in the region are in the pipeline to join the project should UK government provide confidence around a long-term policy framework for CCS.

Many industrial plants produce CO2 through their process, which is separate to emissions from sources of energy. CO2 is produced from the chemical reactions needed to make the product and the quantity is therefore unaffected by energy efficiency measures.

Taking carbon dioxide from the flue gas before it is released into the atmosphere is the only option to decarbonise as there are no viable alternative chemical reactions for these production processes.

[edit] Leading deployment of CCS with industrial clusters

Industry is facing growing pressure to reduce carbon emissions. CCS is the only technology available to significantly reduce industrial carbon emissions, with no change needed to the production plant.

CCS is technologically proven at a commercial scale on industrial plants and there are 22 CCS plants operating across the world, including industrial sites in the US, Canada and United Arab Emirates.

[edit] Why Teesside for CCS?

Home to nearly 60% of the UK's energy-intensive industry, Teesside in Tees Valley is the ideal location to develop the first CCS network in the UK. Being the most integrated industrial cluster in the UK creates economies of scale that will minimise the cost of CCS.

In two instances in Tees Valley chemical plants produce pure CO2 as a by-product, some of this is already captured and transported for use in industries such as food and drink. The area is located on the coastline, with close proximity to storage sites in the North Sea.

Supportive infrastructure and skills are already in place in Teesside and government-funded work has proved Teesside Collective is technically viable and cost effective. Last but not least, local industry is already on board.

[edit] Tees Valley's chemical industry

[edit] Environmental drivers

- Tees Valley produces 13.5m tonnes of CO2 – over 11m tonnes from industrial sources (pre-SSI closure figures).

- Carbon emissions per person are 3x national average.

- Industrial emissions of CO2 have fallen by less than 19% over the past 10 years.

[edit] Economic drivers

- High GVA – £2.5bn GVA per year.

- High productivity – £116,000 GVA per head – over twice national average and 16% more productive than chemical industry elsewhere in UK.

- High wages - £38,900 average – 30% higher than UK average.

- £3.8bn exports.

- Consistent trade surplus – £2bn surplus in 2016.

- £3bn capital investment over the past 5 years.

All industrial clusters across Europe face the same challenges and all are assessing the possibilities of CCS within the context of other decarbonisation opportunities.

[edit] What has Teesside Collective done so far?

To date, Teesside Collective has developed:

- Engineering costs for 3 industrial plants as a starting point including transport and storage of the CO2.

- A business case for an initial CCS hub in Teesside.

- A proposed funding mechanism for industrial CCS across the UK.

- An economic impact assessment of industrial CCS in Teesside. It would create 1,200 jobs during the construction phase and help create and retain 5,900 jobs while in operation.

The Teesside Collective can act as the template for similar networks in other UK regions. There are also good expansion options within the region as it is an ideal location for power plants and hydrogen production technologies.

For example, Tees Valley already produces half of the UK's hydrogen which can be used for heating and transport fuel, planning permission is in process for an 850 MW gas-fired power plant in Teesside, and carbon can be captured from industry and sold to companies to use in commercial products.

[edit] The challenge: commercialising CCS in the UK

CCS is technologically proven at a commercial scale on industrial plants around the world. Its main challenge is financing.

Government needs decarbonisation from the UK's industrial base. In order for CCS to progress to a commercial scale it needs financial support from government.

There is an established precedent for government to support the technological progression and cost reduction of low carbon technologies through deployment, as the example of the UK offshore wind industry shows.

There are many hurdles that would prevent industries in the region from financing industrial CCS entirely on their own at this stage. Commodity industries are lean companies with low margins. There is no financial driver for private investment in CCS and more significantly there is an economic risk of increasing their UK cost base.

[edit] North Sea can store 50+ years of carbon

Transport and storage operation and liabilities are also outside the industrial remit and government's support is needed to ensure access to a suitable store secured in the North Sea.

The Energy Technologies Institute (ETI), a public-private partnership between government and major industry, completed an assessment of UK offshore CO2 storage and concluded that there was enough CO2 storage for over 50 years even from the limited stores that have been appraised.

[edit] Importance of CCS hitting 2050 carbon target

Creating additional pressure is the timing of CCS. The UK needs to start deployment now to realise the full benefits of industrial CCS. The Committee on Climate Change (CCC) believes Industrial CCS will be needed from the mid-2020s onward if the UK is to stay on track for its 2050 emission reduction goals, a message which was reiterated in its June 2017 report to Parliament on meeting carbon budgets.

For this to be achieved, the CCC recommended that contracts be awarded by 2020. Further to this domestic pressure there are international considerations, including the possibility that the UK will lose inward investment to other EU countries.

Norway is pushing ahead with CCS front end engineering and design (FEED) studies on three industrial plants and its government is taking the CO2 leakage liabilities. Rotterdam and Antwerp are also moving forward with CCS projects.

[edit] Demonstrating CCS cost effectiveness

Teesside Collective worked with Pöyry Management Consulting in 2016 to develop a finance model for industrial CCS, intended to kick-start investment in shared infrastructure.

Pöyry has deep commercial experience in CCS as well as regulation and policy making and as part of the UK CCS cost reduction task force has promoted the aim of reducing the cost of the technology and help the UK meet its climate targets.

The finance model is not a direct follow-on from Lord Oxburgh's benchmark report on CCS. However, it does assume a separate State-backed transport and storage company which takes CO2 liability.

This work found that the total cost of industrial CCS in Teesside is £58/tCO2 in total, including access to a transportation and storage network.

[edit] How can the Teesside project kick-start industrial CCS in the UK?

Teesside proposes to start CCS in the UK cost-effectively with the first phase capturing and storing 11 million tCO2 over 15 years. Once the network is proven, this would expand to capture and store 10m tCO2 per year as power stations and more industrial companies join the network.

The first phase would cost £110m to construct and £29m per year to operate, including a transport and storage fee.

The pilot could repay up to £31m per year to government in carbon saving income.

Allow even further cost reduction during FEED stage by choosing one of the two well-characterised UK competition stores, using best available technology and maximising sharing infrastructure.

The pilot could be capturing and storing CO2 in six years.

[edit] What the Teesside project needs from government

- Allocate £15m in FEED funding for the pilot.

- Support investment in a suitable store for Teesside.

[edit] Benefits of industrial CCS: decarbonisation and stimulating investment

Implementing industrial CCS within the next couple of years brings enormous benefits to UK infrastructure. All the modelled scenarios to achieve the UK's legally binding carbon targets require this technology. CCS has the unique ability to reduce carbon emissions by 90% at selected plants.

In addition to allowing the UK to meet its carbon targets at lowest cost, industrial CCS would be a strategic asset for UK – stimulating inward investment in low carbon products, electricity, fuels and heat. Being able to offer clean industrial zones to manufacturers and investors, and low carbon products to their consumers, the UK would be seen as a leader in driving clean growth.

- "CCS on industrial plants is going to be a critical part of the global effort to prevent serious climate change. Teesside is in the right place, at the right time, to get ahead of the curve." – Sir David King, UK's special representative for climate change

- "CCS in industry represents some of the cheapest available carbon abatement in the UK economy…CCS hubs [are] a national infrastructure priority." – Lord Oxburgh's report on CCS

- "The sustainability of the PET we buy is of paramount importance to us. Suppliers who account for their emissions in a credible way will present a fundamentally more attractive proposition in relation to their rivals." – Alison Rothnie, Britvic Plc

This article was originally published here on 18th Oct 2017 by ICE. It was written by Sarah Tennison, Tees Valley Combined Authority.

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Do you take the lead in a circular construction economy?

Help us develop and expand this wiki as a resource for academia and industry alike.

Warm Homes Plan Workforce Taskforce

Risks of undermining UK’s energy transition due to lack of electrotechnical industry representation, says ECA.

Cost Optimal Domestic Electrification CODE

Modelling retrofits only on costs that directly impact the consumer: upfront cost of equipment, energy costs and maintenance costs.

The Warm Homes Plan details released

What's new and what is not, with industry reactions.

Could AI and VR cause an increase the value of heritage?

The Orange book: 2026 Amendment 4 to BS 7671:2018

ECA welcomes IET and BSI content sign off.

How neural technologies could transform the design future

Enhancing legacy parametric engines, offering novel ways to explore solutions and generate geometry.

Key AI related terms to be aware of

With explanations from the UK government and other bodies.

From QS to further education teacher

Applying real world skills with the next generation.

A guide on how children can use LEGO to mirror real engineering processes.

Data infrastructure for next-generation materials science

Research Data Express to automate data processing and create AI-ready datasets for materials research.

Wired for the Future with ECA; powering skills and progress

ECA South Wales Business Day 2025, a day to remember.

AI for the conservation professional

A level of sophistication previously reserved for science fiction.

Biomass harvested in cycles of less than ten years.

An interview with the new CIAT President

Usman Yaqub BSc (Hons) PCIAT MFPWS.

Cost benefit model report of building safety regime in Wales

Proposed policy option costs for design and construction stage of the new building safety regime in Wales.

Do you receive our free biweekly newsletter?

If not you can sign up to receive it in your mailbox here.