Mortar analysis for specifiers

Used correctly, mortar analysis can provide a useful tool in the development of a specification. At worst, it may lead to inappropriate specifications being accepted.

|

|

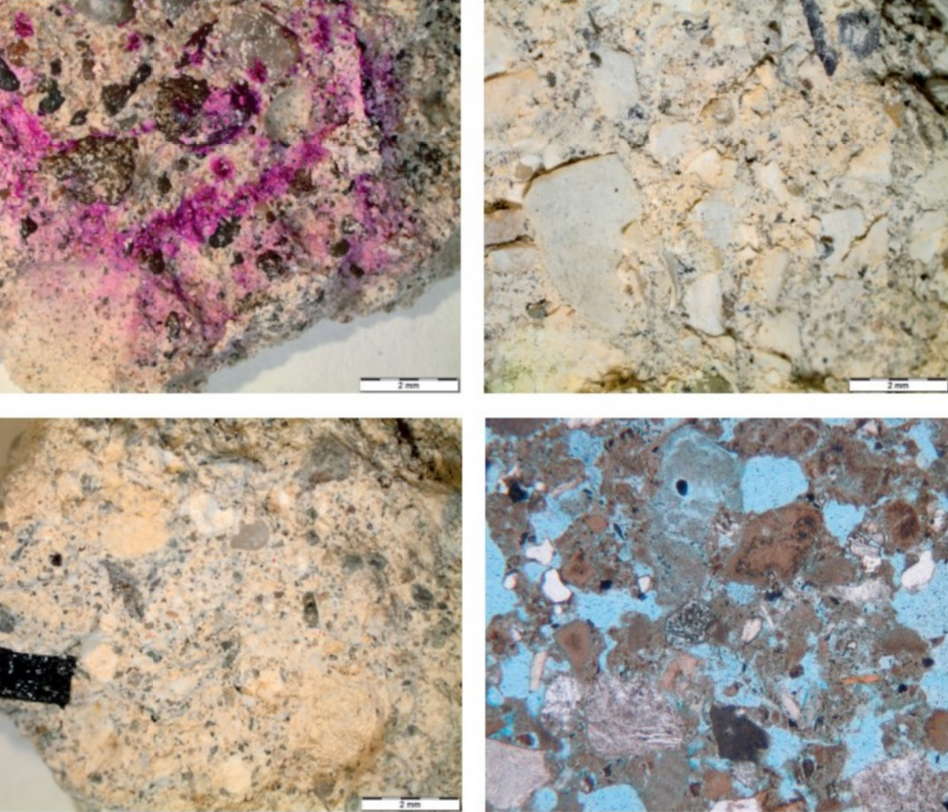

A mortar sample with coal and lime inclusions, from Doune Castle (Photo: Callum Graham, Historic Environment Scotland). |

Contents |

Introduction

Mortar analysis is well established as a method for determining the composition of original mortar mixes found on traditional and historic buildings, and is often seen as the starting point for a repair specification. But how often is scientific analysis really required, and what value can it add for clients and specifiers?

Minimal intervention and like-for-like repair is widely accepted and generally considered best practice for conservation work. When repairing or replacing mortar or plaster finishes a like-for-like approach ensures a good match from an aesthetic and technical perspective, while keeping repairs to the minimum can ensure that earlier finishes are not needlessly removed and replaced for the sake of uniformity. Technically, being able to match the characteristics of earlier mortars and plasters reduces the risk of cracking due to differential movement or weathering due to incompatible materials. Retaining breathability by matching repair mortars can help maintain the equilibrium between mortar and masonry which helps keep buildings dry. Used correctly, analysis can form part of a holistic approach to understanding the construction of a building and for developing an appropriate repair strategy.

Mortar analysis can range from a basic visual and physical assessment to highly-sophisticated scientific testing to determine various properties, as outlined below, so it is useful to know from the outset what kind of information is required and how it might inform future decisions. The more information required, the more expensive it is (a visual analysis and acid digestion test alone costs around £300), so the level of analysis needs to be justifiable from a client’s perspective. [1]

Visual analysis

Inspection in normal conditions and under a microscope of the fresh broken face of the sample, allows an assessment of colour, matched against standardised colour charts, identification of types and sizes of aggregate, the presence of unburned lime, shell or coal inclusions, and additives such as hair. A visual inspection will normally include a basic description of physical qualities, including whether it is soft/hard or friable, and can allow some assumptions to be made about the strength of the mortar. A test for carbonation using a drop of phenolphthalein will indicate whether the mortar has cured properly, and a water-droplet test will provide information about the pore network properties and whether a water repellent had been used.

Wet chemical analysis

Following a visual inspection, acid digestion is the most common method of chemical mortar analysis. A sample of dried mortar is weighed, lightly crushed and placed in dilute acid to dissolve its lime content, leaving behind any insoluble aggregate. This method is used to establish the mix proportions of the sample. It has limitations as the acid will also dissolve aggregate containing calcium carbonate, such as limestone or shell, and any lime inclusions. This method of analysis will not establish the level of hydraulicity in a mix or identify additives such as gypsum or other minerals. A secondary test is a measure of soluble silica – used to give an indication of hydraulic components.

Specialist testing

A range of laboratory testing can be used to establish the properties and characteristics of mortars and plasters. Petrographic analysis involves taking a thin section of the mortar for visual inspection under a microscope to determine the pore structure, aggregate and binder constituents, and method of mortar preparation. Scanning electron microscopy (SEM) will show up further details of the microstructure. Mercury intrusion porosimetry (MIP) tests will give an indication of porosity and pore size distribution, while other methods such as X-ray diffraction (XRD) and gas chromatography can be used to identify crystalline components or organic additives, respectively. Most of these, and other specialist tests, are reserved for more in-depth study of mortars, usually as a wider research programme. They may not be necessary or justifiable for small projects, however fascinating the results may be.

Benefits and limitations

Mortar analysis is an empirical research method which may be commissioned for various reasons. These may be academic, technical or both. For example, it can help to determine the causes of failure or deterioration of a mortar; the materials used in the construction; whether there are different phases of construction; and where repairs have been carried out in the past, and how successful these have been.

Statutory authorities sometimes request mortar analysis as supporting evidence for listed building consent or grant funding applications in order to demonstrate that a repair specification is compatible. This can cause analysis to become a tick-box exercise which does little to inform the repair specification in any meaningful way. Even worse, analysis results can be adopted in lieu of a full specification, creating a risk of inappropriate mortar being used without considering whether it is fit for purpose.

All methods of analysis provide information about the mortar, but there are limitations which specifiers that those commissioning analysis should be aware of. Taking mortar samples is usually a destructive process (unless the mortar is already detached or has failed). Statutory consent may be required if taking samples from a scheduled monument. To avoid any possible misunderstanding, permission should always be gained in advance if a building is listed.

Mortar analysis can sometimes help provide information about the date of the building, particularly if supported by archival evidence, but care has to be taken in the sampling method and interpretation of results for this purpose. Often the estimated date of construction (provided by the sampler) is taken as the date of the mortar. This also creates the potential for error, as the information supplied with the mortar sample may not be representative or accurate.

Off-site mortar analysis (as carried out in a laboratory) will provide information only about the sample provided, not the building as a whole. Therefore, the value of the analysis is dependent on accurate information being provided with the sample. To gain a representative view of the mortar(s) used in the building, several samples may be required from different areas of construction, different phases of the building, and different applications (such as building, harling, pointing mortar or plaster).

Informing specifications

A mortar analysis report is not a specification, although it is often mistaken as such. Typically, it will include a section suggesting how the mortar can be best ‘replicated’, but this is subjective, and comes with qualifications, including availability of materials. Furthermore, there are many other factors to consider, including the nature of the substrate and its condition, and the exposure of the structure. [2] For example, the original mortar used to construct the wall of a now-ruined property is unlikely to be appropriate to consolidate an exposed wallhead devoid of a roof and weathering details to protect it.

If it is specification that is desired, the starting point is what is required for the building to perform and meet the necessary expectations, including authenticity of materials or application method. Analysis may form part of the information used to develop a repair specification, but it should not take the place of appropriate condition assessment and evaluation of the structure.

Clients may be surprised at the basic nature of some of the tests undertaken by laboratories, and the assumptions that follow. It is not uncommon for example for a ‘snap’ test to be undertaken (simply breaking the sample by hand) on which is then based a supposition about the hydraulicity of the mortar. The danger is that this is largely subjective, may vary between analysists or technicians, and depends on the quality and condition of the sample. It is unlikely to provide any meaningful guidance towards a specification where the strength of the mortar is an issue. Equally, acid digestion is routinely used to give an indication of binder-to-aggregate ratios, but it is unreliable as it also dissolves calcium-carbonate based aggregates and inclusions. These tests are therefore indicative and cannot be used to reliably inform a repair specification.

A valuable element of a mortar analysis is the aggregate identification. The importance of specific aggregates to the appearance and performance of a mortar can be overlooked and may even be missed out of repair specifications. Having original aggregate graded, identified and matched as part of a mortar analysis is of use in identifying a suitable aggregate for the repair mortar. Basic mortar analysis will not normally identify additives used in the original mix, although common additions such as hair or shell will generally be picked up by visual inspection.

Mortar analysis can give an indication of the method of manufacture (whether it was hot-mixed, putty or dry hydrate) but, again, while the clues may be evident within the basic visual inspection, they are elucidated only by advanced methods of analysis, such as SEM microscopy or pore-structure analysis. With all these assumptions and qualifications, when should specifiers or conservation officers request a mortar analysis, and how should they interpret the results?

When is mortar analysis required?

On some level, an analytical approach to observing and understanding lime mortar should be a skill that all conservation professionals and particularly specifiers should develop. The ability to recognise features of lime mortars, and describe the colour, texture, presence of lime and other inclusions, shell and aggregate size and appearance is something that can be developed over time simply by routine observation. This is not to undermine the value of specialist analysis, but the question should not be ‘should I get a mortar analysis?’ but ‘what do we want to learn from analysing the mortar and how will we use the information?’ A competent conservation-accredited building surveyor, architect or other professional tasked with specifying mortars should be able to make observations about the mortars found in buildings, and to understand when further information from a specialist analysis is necessary.

Mortar analysis is required whenever there is insufficient information available about the existing mortar to enable a repair specification to be developed, or where there is a need to understand the particular characteristics of a mortar which cannot be identified from a site inspection (such as reasons for failure). In this respect it would normally form part of any significant mortar-repair proposal. Clients and statutory bodies should request a mortar analysis if there is uncertainty about the appropriate repair specification for a traditional or historic building, and particularly if large-scale works are proposed using lime-based or other materials.

Mortar analysis results should always be considered in the light of the condition of the building, its proposed and existing uses, the overall repair approach being implemented and the maintenance plan. If used to help with matching new mortar to existing or original materials, the mortar analysis should be accompanied by a comprehensive explanation of the findings, and should be read with an awareness of the limitations of the data.

Used correctly, mortar analysis can provide a useful tool in the development of a specification. At worst, it may lead to inappropriate specifications being accepted simply by virtue of having an analysis attached.

References

- [1] For more information on analysis methods, see Historic England (2012) Practical Building Conservation: mortars, renders and plasters and Peter Ellis (2002) The Analysis of Mortar: the past 20 years, Historic Churches.

- [2] For further guidance on mortar specification, see Historic Environment Scotland, Short Guide: lime mortars in traditional buildings, and Roz Artis (2018) Specifying Hot-Mixed Mortars, HES Technical Paper 28.

- [3] See HES Refurbishment Case Study 25, Haa of Sand, Shetland ( 2016).

This articles originally appeared in IHBC’s Context 154, published in May 2018. It was written by Jessica Hunnisett, a conservation-accredited chartered building surveyor and senior technical officer at Historic Environment Scotland. The author acknowledges the contributions of Dr Callum Graham and Dr William Napier in the preparation of this article.

--Institute of Historic Building Conservation

Related articles on Designing Buildings Wiki

- Conservation officer.

- Conservation.

- Conserving Burns Monument.

- Defects in stonework.

- Finding stone to conserve historic buildings.

- Hemp lime construction: A guide to building with hemp lime composites.

- Hot-mixed mortars: the new lime revival.

- IHBC articles.

- Lime mortar.

- Mortar.

- Portland cement.

- Sourcing stone to repair Exeter Cathedral.

- The Institute of Historic Building Conservation.

- The use of lime mortar in building conservation.

- Technical Paper 32 – A Data Driven Approach to Understanding Historic Mortars in Scotland.

- Types of mortar.

- Types of stone.

IHBC NewsBlog

RICHeS Research Infrastructure offers ‘Full Access Fund Call’

RICHesS offers a ‘Help’ webinar on 11 March

Latest IHBC Issue of Context features Roofing

Articles range from slate to pitched roofs, and carbon impact to solar generation to roofscapes.

Three reasons not to demolish Edinburgh’s Argyle House

Should 'Edinburgh's ugliest building' be saved?

IHBC’s 2025 Parliamentary Briefing...from Crafts in Crisis to Rubbish Retrofit

IHBC launches research-led ‘5 Commitments to Help Heritage Skills in Conservation’

How RDSAP 10.2 impacts EPC assessments in traditional buildings

Energy performance certificates (EPCs) tell us how energy efficient our buildings are, but the way these certificates are generated has changed.

700-year-old church tower suspended 45ft

The London church is part of a 'never seen before feat of engineering'.

The historic Old War Office (OWO) has undergone a remarkable transformation

The Grade II* listed neo-Baroque landmark in central London is an example of adaptive reuse in architecture, where heritage meets modern sophistication.

West Midlands Heritage Careers Fair 2025

Join the West Midlands Historic Buildings Trust on 13 October 2025, from 10.00am.

Former carpark and shopping centre to be transformed into new homes

Transformation to be a UK first.

Canada is losing its churches…

Can communities afford to let that happen?

Comments

This is the best I have ever read about the subject! Thank you!

Erik