Assessing moisture in porous building materials

Despite the plethora of techniques that are available for assessing moisture in traditional porous building materials, none is completely effective, and all have their limitations.

|

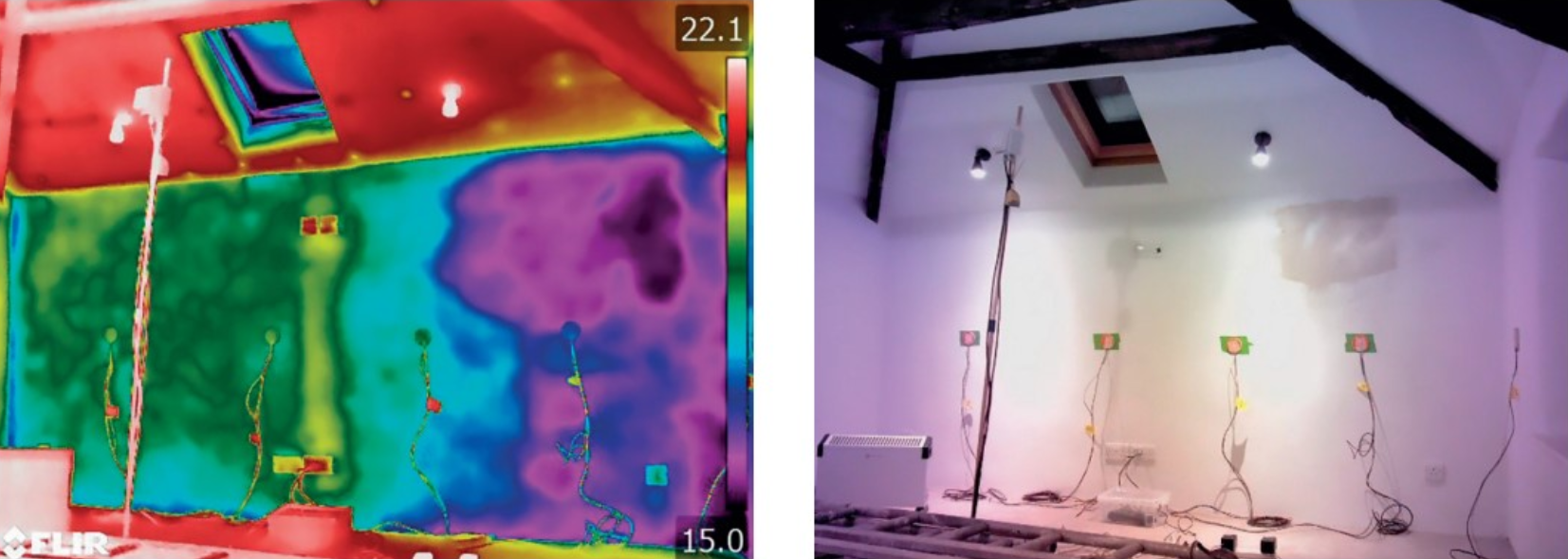

| The passive thermal image of a wall has detected moisture ingress from the chimney on the right hand half of the rear east elevation of a house in Cumbria. The purple indicates damp areas. |

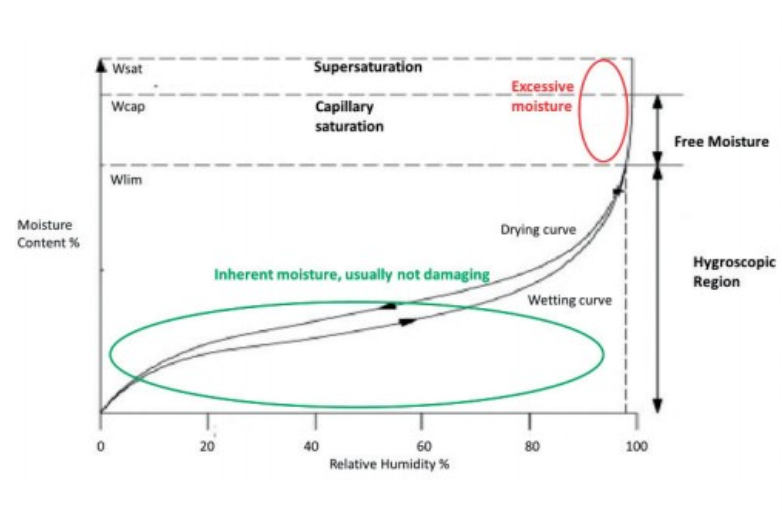

All traditional building materials are semi-porous and contain some inherent moisture. It is important to differentiate between a building in its ‘natural’ state, that is in equilibrium with the surrounding air, and a building that is suffering from damp. Inherent moisture is usually not problematic unless it accumulates over long periods. Damage occurs when there is an excessive amount of moisture, known as free moisture, which is caused by liquid water.[1] Different ranges of measuring moisture are suitable for differing ranges of moisture conditions. Some methods are appropriate in the hygroscopic range at relative humidities below 95-98 per cent, while others are more applicable in the capillary range at relative humidities above 98 per cent.

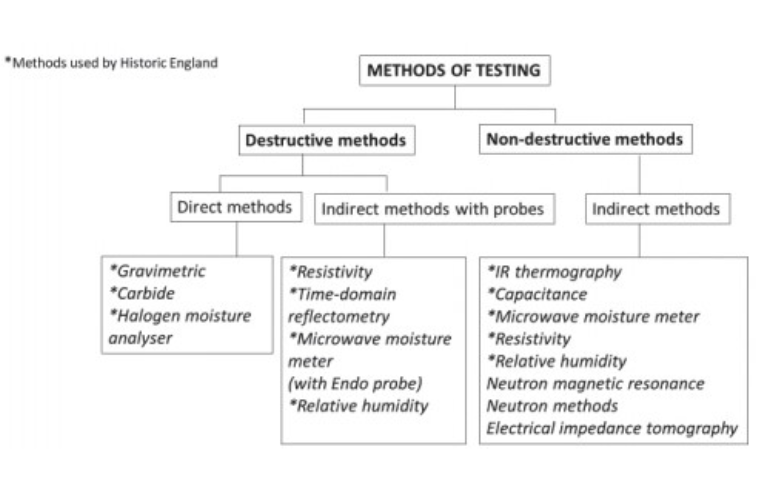

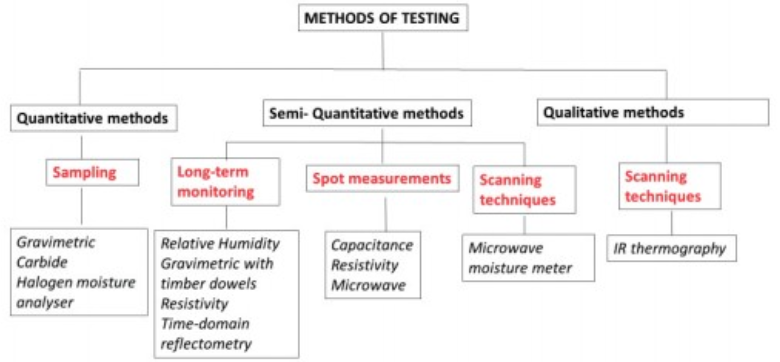

There are many ways to measure moisture, some destructive and others not. Moisture content can be measured either directly or indirectly, based on a variety of physical phenomena. Some are quantitative, measuring absolute moisture content. The majority are semi-quantitative, meaning that they can relate readings to the relative moisture content of materials. If calibration of these techniques is possible, readings can represent actual moisture content. Both semi-quantitative and qualitative methods are reliable only when used comparatively. Differing strategies are available, depending on what is required.

Despite the plethora of techniques available, none is completely effective, and all have their limitations. Comparative information on performance and how they should be used in situ is lacking. There is a lack of confidence in their accuracy and their comparability. There are difficulties in interpretation as techniques are based on different scientific principles. To address this knowledge gap, Historic England commissioned Heather Viles of Oxford University to compare the performance of different methods of assessing moisture in porous building materials.[2] The research tested 12 non-invasive and five invasive moisture measurement methods on sample blocks of masonry in the laboratory under controlled conditions. They examined how the techniques performed under drying and wetting conditions by plotting gravimetrically determined moisture contents against individual meter readings.

The gravimetric test method is the most accurate as it determines the absolute moisture content by comparing the wet weight of a sample to its oven-to-dry weight. It is often used as a benchmark for comparing all other methods or for calibration.[3] However, it can still give a wide range of moisture contents across one wall because of natural material variability, contaminants and the non-homogeneity of traditional building materials.[4] In most instances, gravimetry is unnecessary, unfeasible and sometimes not permitted as it requires a sample of the material to be taken. It cannot be used to compare moisture contents of dissimilar masonry materials because of their differing moisture storage functions.

The method should not be confused with gravimetric methods using proxy materials. One well-established example of this is to insert timber dowels into predrilled holes and leave them there until their moisture content stabilises. This proxy material can then be removed for gravimetric analysis, minimising the destruction of original fabric. Using timber dowels in this way is inexpensive and can be a good indicator of moisture content, provided that conditions are not saturated. The method is used to monitor relative changes in a wall, and can be repeated at intervals. The underlying principle is that equilibrium is achieved between the moisture content in the masonry and the timber dowel. However, there are limitations: the dowel and the surrounding fabric require good contact but often, to enable the dowel’s easy retrieval, there is a small air gap that can affect the readings. Second, the dowel requires time to equilibrate to the environment, which may cause a considerable lag in the values obtained, and once saturated can give ‘wet’ readings for a long time.[5]

Nonetheless, in laboratory tests the timber dowel gave a good range of readings, and experience in the field suggests that this method can be a reliable indicator of moisture content, provided that conditions are not saturated. The underlying principle is that to 30 cm, with the Endo probe inserted into a narrow borehole. Using the non-destructive sensor heads, subsurface information can reportedly be revealed to a depth up to 80 cm using four different sensing heads (3 cm, 11 cm, 30 cm and 80 cm). Depth penetration tests were carried out on the 3 cm and 11 cm heads. The results for the 3 cm sensing head were reliable but the results for the 11cm heads were ambiguous.

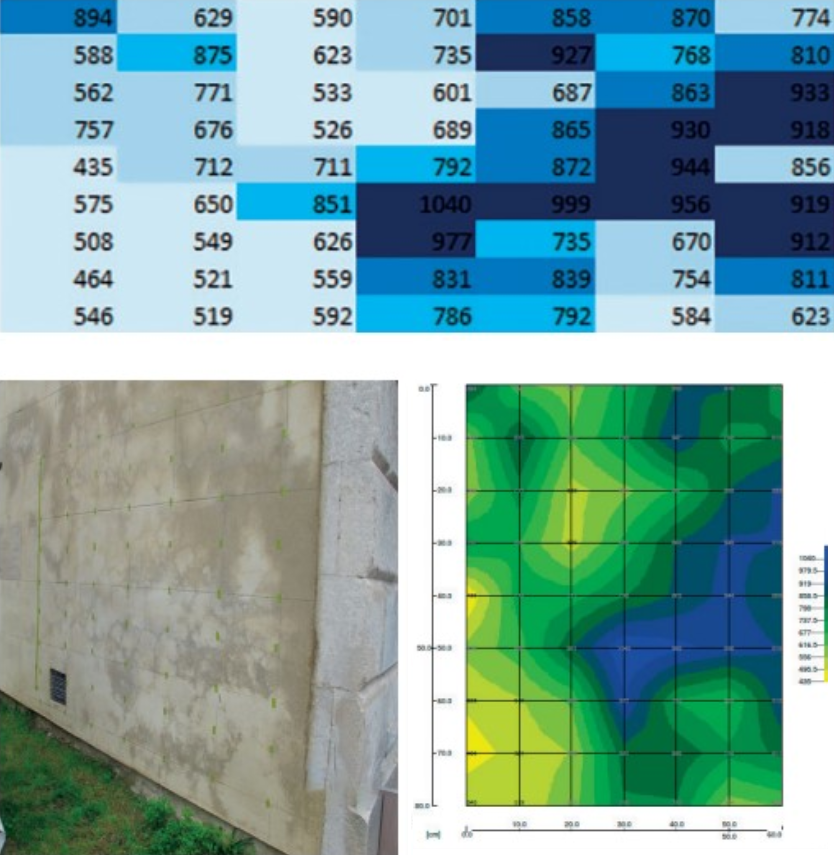

The microwave moisture meter provides a spatial distribution of moisture and is not affected by salts. However, materials such as metals, voids and rough surface textures can interfere with the readings. If calibrated, the meter can give quantitative readings, but it is most reliable as a comparative technique. More work is needed to be able to correlate the values of a range of materials to known moisture scales such as relative humidity. This will help in the interpretation of the readings. So far when used in situ the measurements have been carried out with other techniques for this reason.

Both the microwave moisture meter and infrared thermography, another non-destructive scanning technique, can analyse large areas at a glance and provide moisture maps that can be overlaid with detailed information of condition. However, infrared thermography does not measure moisture, but rather the temperature of a surface.

There are two forms of thermography: passive and active. Passive thermography captures the natural thermal patterns of a surface, where blue/purple areas are ‘cold’ and red/yellow areas are ‘warm’. Active thermography requires energy (heating or cooling) to create temperature differentials. This method can sometimes be used to locate sub-surface moisture, to diagnose roof defects after a warm sunny day, for example. It relies on the fact that water has a higher thermal capacity than most building materials and retains heat for longer, so in this instance wet areas will appear warm, and dry areas will appear cold.

In most situations, a qualitative analysis is sufficient. If quantitative measurements are required, the emissivity of the material and the reflected apparent temperature need to be determined. In general it is good practice to input these values whenever this method is employed. Thermal imaging has many limitations: the most critical is to carry out the survey during appropriate weather conditions as otherwise the results can be misleading. Further, background knowledge of the site is necessary as what may appear to be moisture may actually be missing insulation, air leakage or other deficiencies unrelated to moisture.

|

| Regimes of moisture storage in hygroscopic porous building materials. |

|

| Common methods of moisture assessments categorised by destructive (direct and indirect) and non-destructive techniques. |

|

| Techniques categorised by quantitative, semiquantitative and qualitative methods, and different strategies of moisture. |

Overall, the results from the research suggests that most of the techniques tested in the laboratory can give good, semi-quantitative estimates of moisture levels. However, some devices perform better than others. Of all the capacitance and resistivity meters tested, the CEM capacitance and the Resipod resistance devices gave the best estimates of moisture content over a wide range of moisture conditions, from near-dry to near-saturated.

|

| Moisture map of a section of a wall using the microwave moisture meter: (clockwise from top) spreadsheet with measured values; digital image from the meter; visible light image. |

Other proprietary conductivity and capacitance meters gave a variable performance. This was not surprising given that they are calibrated for a particular material. For example, Protimeters are pre-calibrated for timber, so they will be unreliable when used quantitatively for stone, brick or plasters. Furthermore, the majority gave consistent results only over a narrow range of moisture contents and were unreliable at near-saturated conditions. All were affected by salts and metallic elements close to the surface of the measurement location. Consequently, these types of devices are best used for comparative analysis in the low-to-mid range of the hygroscopic region, and where there are no salts or metals near the surface to interfere with the readings. Their main advantage is that they can provide a rapid, non-destructive method of identifying levels of moisture by giving comparative measurements.

Performance also varied depending on the type of building material. Comparing three electrical meters (capacitance CEM and FMW and Protimeter in M-mode), the CEM meter gave more consistent readings than the other devices over a wide range of moisture content for limestone and brick.

The Protimeter and the FMW meter only produced reasonably reliable readings for limestone and brick at moisture contents roughly below three and four per cent respectively. Another disadvantage of these meters is that they are only capable of one-off readings. In most instances for historic buildings monitoring of long-term trends is necessary as conditions are never static.

Evaluation of changes of moisture contents can be used in different contexts, from monitoring the effect of an intervention, to drying after a catastrophic event, to assessing seasonal differences. The readings provide proxy moisture contents which are indicators of condition only. Monitoring will identify whether the material is drying, getting wet or has reached equilibrium.

There are several ways of monitoring in situ, of which resistivity and humidity measurements are the easiest to implement. Both techniques can be resource heavy as they require a power supply, data logging and sensing equipment, but once installed they can be managed remotely.

The sensors can be attached to the surface, embedded or fixed at the interface between the wall and another material. In the field, resistivity (wooden blocks attached to electrodes) and Honeywell humidity sensors placed at the interfaces between fabric and internal wall insulations have proved to be successful. However, initial laboratory testing of an embedded Rotronic humidity sensor only provided wet or dry readings, suggesting that humidity sensors may not recover if kept for prolonged periods at relative humidities greater than 98 per cent. At saturated conditions, the same could apply to the timber resistance sensors. Given that the area of interest is the hygroscopic region, arguably this is an acceptable level of risk, and field experience has shown that both types of sensors do recover as moisture levels fall.

There are many factors that affect the assessment of moisture. Interpretation is challenging as the techniques are based on a variety of different principles. Many only have arbitrary scales that display values from 0-100, 0-200 or into the thousands. These values are simply non-absolute indicators of higher or lower moisture content. Furthermore, the value of the measurements depends on the experience of the user to interpret the results. Practical issues of handling between practitioners also influence the readings: some require good contact, and with others the amount of pressure applied or the degree to which the probes have penetrated a substrate affect the measurements.

Calibration is another factor as commercial devices are usually calibrated for one type of material. Manufacturers sometimes provide conversion tables or specific calibration values for generic materials, but evaluating their accuracy is difficult because of the non-homogeneity of historic materials, ageing, salts and weathering. Most historic buildings are composite structures, which adds another level of complexity.

Note

The experiments described in this article on evaluating a range of moisture measurement methods are for specific applications for historic building materials. These applications are not the standard uses for which the instruments were designed. Any comments or results given about their performance are specific to the tests conducted and do not represent any criticism about their application under standard use.

Acknowledgements

Heather Viles, professor of biogeomorphology and heritage conservation, and Hong Zhang, research technician, both at the school of geography and the environment, Oxford University; Scott Orr, lecturer, UCL Institute for Sustainable Heritage; Iain McCaig, senior building conservation advisor, Historic England.

References

- [1] Straube, John (2006) ‘Moisture and Materials’, Building Science Digests 138, October.

- [2] Viles, H, Zhang, H and Orr, S (2019) Unpublished report for Historic England, Damp Monitor: a comparative evaluation of methods to monitor moisture in historic porous masonry materials, School of Geography and the Environment, Oxford University.

- [3] ASTM (2003), Standard Test Methods for Use and Calibration of Handheld Moisture Meters, D4444-92.

- [4] Brian Ridout has gravimetrically measured the moisture content of three courses of brick and found a range of moisture content values from less than one per cent to greater than six per cent. See Ridout, B and McCaig, I (2016), Measuring Moisture Content in Historic Building Materials, Historic England.

- [5] According to Paul Baker, Glasgow Caledonian University, it takes nine days for a wooden dowel to equilibrate to the surrounding masonry. See Baker, P, Galbraith, G, McLean, RC and Nicol, D (2007), Evaluation of the use of wooden dowels as a technique for the measurement of the moisture content in masonry, Engineering Historic Futures Research Report.

This article originally appeared in IHBC's Context 164 (Page 12), published by The Institute of Historic Building Conservation in March 2020. It was written by Soki Rhee-Duverne, a building conservation advisor for the building conservation and geospatial survey team at Historic England, specialising in energy efficiency and the hygrothermal performance of historic buildings.

--Institute of Historic Building Conservation

Related articles on Designing Buildings Wiki

- Carbide meter.

- Conservation.

- Damp in buildings.

- Diagnosing the causes of dampness (GR 5 revised).

- Electrical resistance meters.

- Heritage.

- Humidity.

- IHBC articles.

- Institute of Historic Building Conservation.

- Methodology for moisture investigations in traditional buildings.

- Penetrating damp.

- Retrofit and traditional approaches to comfort.

- Rising damp in walls - diagnosis and treatment (DG 245).

- Rising damp.

- Thermography for traditional buildings.

IHBC NewsBlog

Old Sarum fire in listed (& disputed) WW1 Hangar - Wiltshire Council has sought legal advice after fire engulfed a listed First World War hangar that was embroiled in a lengthy planning dispute.

UK Antarctic Heritage Trust launches ‘Virtual Visit’ website area

The Trust calls on people to 'Immerse yourself in our heritage – Making Antarctica Accessible'

Southend Council pledge to force Kursaal owners to maintain building

The Council has pledged to use ‘every tool in the toolbox’ if urgent repairs are not carried out.

HE’s Research Magazine publishes a major study of the heritage of England’s suburbs

The article traces the long evolution of an internal programme to research 200 years of suburban growth

IHBC Context 183 Wellbeing and Heritage published

The issue explores issues at the intersection of heritage and wellbeing.

SAVE celebrates 50 years of campaigning 1975-2025

SAVE Britain’s Heritage has announced events across the country to celebrate bringing new life to remarkable buildings.

IHBC Annual School 2025 - Shrewsbury 12-14 June

Themed Heritage in Context – Value: Plan: Change, join in-person or online.

200th Anniversary Celebration of the Modern Railway Planned

The Stockton & Darlington Railway opened on September 27, 1825.

Competence Framework Launched for Sustainability in the Built Environment

The Construction Industry Council (CIC) and the Edge have jointly published the framework.

Historic England Launches Wellbeing Strategy for Heritage

Whether through visiting, volunteering, learning or creative practice, engaging with heritage can strengthen confidence, resilience, hope and social connections.