JW Evans silverware factory

A conserve-as-found approach, even for the service installations, has retained the atmosphere of one of the most complete surviving historic factories in Birmingham’s Jewellery Quarter.

|

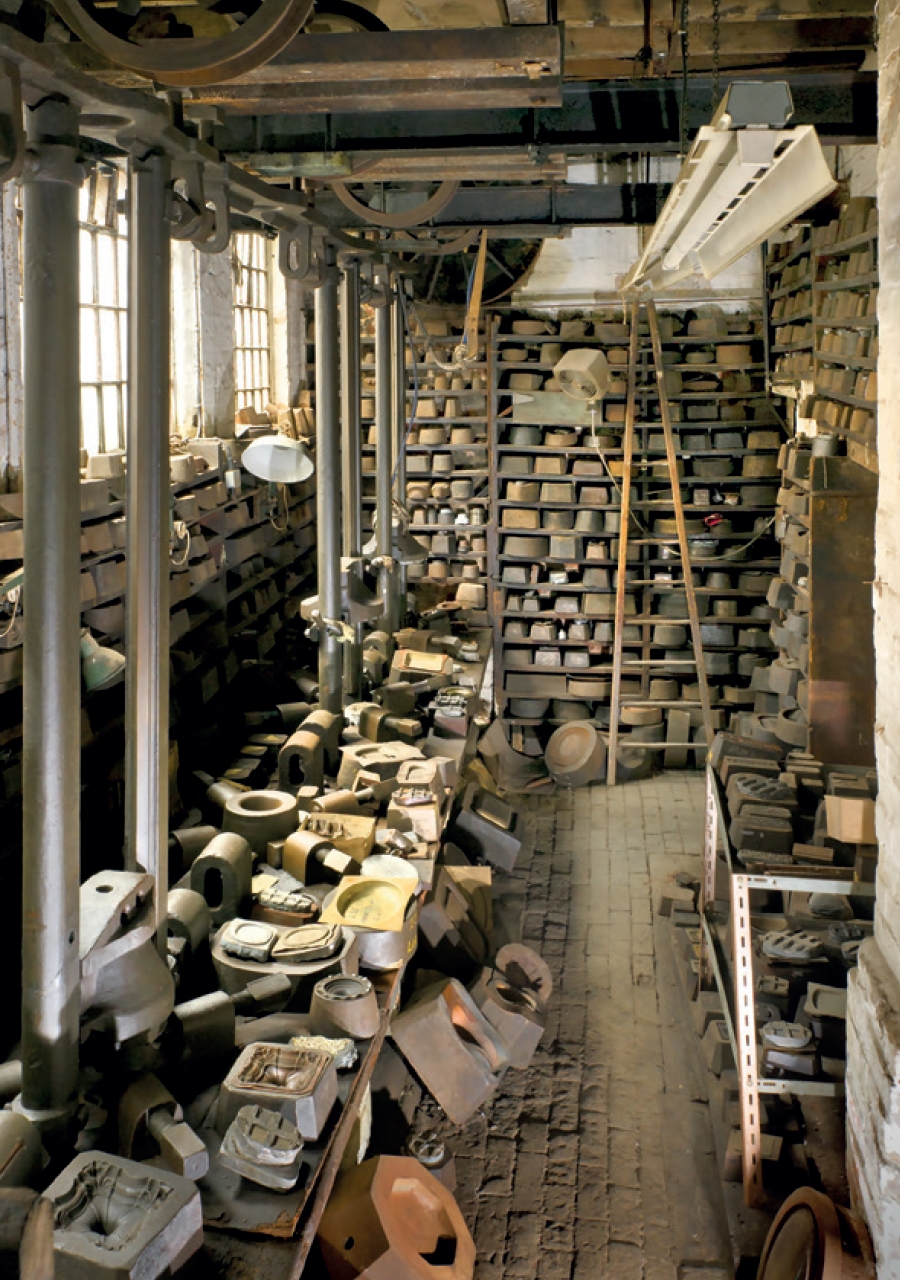

| A fly-press shop on the first floor, after completion. The roof and the failed plaster ceiling were renewed, but all the room contents were retained in situ throughout the works. (Photo: Historic England). |

Contents |

Introduction

The JW Evans silverware factory in Birmingham’s Jewellery Quarter, managed by a single family from its foundation in 1881 to its closure in 2008, represents a unique and remarkably complete survival. The factory was the subject of a major rescue project carried out by English Heritage in 2008–11, and is now an English Heritage property open to the public.

The extraordinary atmosphere of the interior encouraged a radical approach to be taken to the rescue work, never attempted on this scale previously in the UK. Throughout the programme of major repairs, the aim was that the whole of the contents of the building should be preserved in situ and untouched. The ‘conserve as found’ approach was taken here to its logical extreme, and applied even to the service installations.

Established in 1881, JW Evans is one of the most complete surviving historic factories in Birmingham’s Jewellery Quarter. Behind the terraced house frontage, the workshops retain their original drop-stamps and fly-presses, and are packed with thousands of dies for the manufacture of silverware as well as the whole of the working equipment, stock and records of the business. To walk into the factory is to step into a lost industrial world.

The buildings themselves are unexceptional, built of brick and slate, with a typical early 19th -century terrace row at the front, and long ranges of late 19th-century workshops behind. Inside, the reason for the Grade II* listing becomes clear. The workshops preserve the most extensive surviving battery of drop-stamps in the Jewellery Quarter, complemented upstairs by ranges of fly-press shops. All are narrow, constricted spaces, linked by steep stairs, and densely packed with equipment. Machinery of all ages is crammed into every corner, from a unique Keller Pantograph machine bought around 1905 and disused since 1939, to post-war power presses, compressors for gas-and-air torches and a modern electric kiln.

Every inch of wall space in the workshops is lined with shelving, bowed under the weight of 30,000 dies, cutting and piercing tools. The larger and heavier dies are piled up on the floors and benches. Parts of candlesticks, condiment sets, sauceboats, jugs and trays line the shelves. Some areas of the factory have been abandoned for decades and are thick with dust. Others, remarkably, show signs of more recent use, with steel tools still gleaming brightly from their racks.

Conservation philosophy

From the outset, it was clear that the project would involve great challenges. How would it be possible to carry out the major repairs and other necessary interventions without destroying the extraordinary character of the site? A comprehensive programme of repairs was necessary, with full re-roofing and major structural repairs. The whole of the building’s services would need to be replaced and upgraded, the interiors conserved or refurbished, and the future of the densely-packed contents secured.

After much investigation and debate, it was agreed to apply a radical conserve-as-found approach to the historic interiors. ‘Conserve as found’ is a familiar phrase in the conservation world and the approach has been pursued on a number of well-known projects. The National Trust’s Calke Abbey in Derbyshire is presented as it was at the time of the Trust’s acquisition, to preserve this great house’s faded grandeur. At Brodsworth Hall in Yorkshire, English Heritage took a similar, even more thorough-going approach to the time-worn interiors. A much closer comparison to JW Evans is the Museum of the Jewellery Quarter, which includes a former jewellery workshop, presented as an industrial time capsule, with all of its machinery, tools and equipment.

But in each of these cases, and others like them, the buildings and their contents have all been through an intensive conservation process. To carry out the major works, the whole of the contents were carefully recorded, catalogued and removed. With the contents removed, access can be readily obtained to allow full conservation, refurbishment and re-servicing of the building interior. Each object has been through a process of thorough conservation, before being carefully reinstated in its original position.

In assessing the effect of such an approach, it was realised that applying it to JW Evans would destroy much of the very character that gave the place such special significance. No matter how painstakingly executed, the end result would create a sanitised environment, far removed from the authenticity of the site as it had been inherited. The undisturbed Evans interiors present an extraordinary, captivating atmosphere, with an authenticity which has to be experienced to be fully appreciated. But how does one preserve an atmosphere? The answer is obvious: by leaving it alone.

For all of the key rooms of historic significance, the starting point was therefore that everything – the bowed racks full of dies, all the objects piled high on benches and floors, the contents of drawers, the grime, the rust, even the dust – would be left exactly as they were, untouched and in situ. This was indeed an extreme and radical concept, never attempted before on this scale in the UK.

The conservation philosophy and ensuing development of the project concept established another key principle. Evans was to be preserved in all of its utilitarian, workaday and often ramshackle character. In conserving Evans, the question was ‘Will it last if nothing is done?’ not ‘Is it attractive?’. The urge to tidy up, or remove modern accretions and blemishes, had to be strongly resisted. That issue applies with particular force to services installations.

Services

The first principle of the services installation was therefore that all redundant services, instead of being stripped out, were retained. This applied not only to the older, more robust services, such as gas and water pipes or steel electrical conduits, but also the more recent installations, such as pvc electrical cabling. The existing cables, a tangle of largely surface-fixed wiring of many periods, were retained in situ wherever possible. The gas and water pipes which snaked all around the building were capped off and retained, although all pipework had to be accessed for draining down or purging. All the redundant equipment, such as gas heaters, blow-torches or electric motors, was simply left in place.

A complete new electrical system, with lighting and occasional power sockets, had to be fitted throughout. It was agreed that, wherever possible, existing conduits, switches and light fittings should be re-used. The electrical subcontractor entered into the spirit of the project, threading cables around the building with endless patience to avoid disrupting the contents, even, where possible, drawing new wires down rusty old conduits. The workshops were fitted mainly with utilitarian fluorescent lights, which were re-used, with new innards where necessary. In the front houses, light fittings were generally pendant bulbs, without shades or fittings – so readily matched, at least while tungsten bulbs are still available. Some new metal-clad power sockets or light switches had to be provided in the workshops, but these blended well with the industrial ethos.

No fixed heating was fitted in the core historic areas, which had mainly relied on heat from the work processes or gas fires. As the use of these areas was limited to guided tours, it was agreed that no comfort heating was needed. In terms of protection of the building contents, the improvement in environmental conditions from the building repairs would have to suffice. It was recognised that the processes of deterioration would continue, albeit more slowly. If the attempt to control deterioration would itself bring loss and destruction, such intervention was of no benefit. New fire detection and security systems were also required in all areas, but this was more straightforward, as such systems can be largely radio-based, without wiring.

The end result of the conserve-as-found approach has been remarkably successful in retaining the authentic atmosphere of the building. For the service installations in particular, it was an exceptional project, with very few parallels elsewhere. Towards the end of the re-wiring, the electrician, by now a convert to the peculiar demands of the project, made his own contribution. Instead of fitting new fluorescent tubes everywhere, he saved the best of the old tubes – covered, like the rest of the factory, with a characteristic layer of dust.

|

| One of the stamp shops after completion of the project, with dropstamps and dies (Photo: Historic England). |

For a fuller account of the project, see Transactions of the Association for Studies in the Conservation of Historic Buildings, Volume 34 (2011), Cathedral Communications Limited, 2012.

This article originally appeared as ‘Authenticity? Leave it alone’ in IHBC's Context 159 (Page 17), published in May 2019. It was written by Nick Hill, a chartered building surveyor and national conservation projects manager with Historic England.

--Institute of Historic Building Conservation

Related articles on Designing Buildings Wiki

- Architecture of the industrial revolution.

- Building services.

- Conservation areas and protecting open space.

- Conservation.

- English Heritage.

- How to make conservation areas work.

- IHBC articles.

- Nineteenth century building types.

- Shrewsbury Flaxmill Maltings.

- The Angel Awards.

- The Institute of Historic Building Conservation.

- The Victorian Society's top 10 endangered buildings 2019.

IHBC NewsBlog

Latest IHBC Issue of Context features Roofing

Articles range from slate to pitched roofs, and carbon impact to solar generation to roofscapes.

Three reasons not to demolish Edinburgh’s Argyle House

Should 'Edinburgh's ugliest building' be saved?

IHBC’s 2025 Parliamentary Briefing...from Crafts in Crisis to Rubbish Retrofit

IHBC launches research-led ‘5 Commitments to Help Heritage Skills in Conservation’

How RDSAP 10.2 impacts EPC assessments in traditional buildings

Energy performance certificates (EPCs) tell us how energy efficient our buildings are, but the way these certificates are generated has changed.

700-year-old church tower suspended 45ft

The London church is part of a 'never seen before feat of engineering'.

The historic Old War Office (OWO) has undergone a remarkable transformation

The Grade II* listed neo-Baroque landmark in central London is an example of adaptive reuse in architecture, where heritage meets modern sophistication.

West Midlands Heritage Careers Fair 2025

Join the West Midlands Historic Buildings Trust on 13 October 2025, from 10.00am.

Former carpark and shopping centre to be transformed into new homes

Transformation to be a UK first.

Canada is losing its churches…

Can communities afford to let that happen?

131 derelict buildings recorded in Dublin city

It has increased 80% in the past four years.