Polyurethane spray foam in structurally insulated panels and composite structures

[edit] History

First produced by the German-born industrial chemist Otto Bayer in 1937, versions of polyurethane today are ubiquitous and go largely unnoticed in many products throughout the world. While early compounds focused on the production of fibres and flexible foams (polyurethanes were used on a small scale as an aircraft coating during World War 2), since polyurethane became commercially available in 1954 ever more applications have been found.

For more information, see Polyurethane (PUR).

[edit] Benefits

Polyurethane foam is one of the most efficient insulating materials available, offering thermal conductivity of around 0.020 W/m2K. To put this into perspective, a brick wall would have to be 860 mm thick to achieve a comparative level of insulation to 25 mm of polyurethane foam (or 45 mm of mineral wool insulation, 140 mm of softwood, or 380 mm of concrete block).

In addition, as a closed-cell foam applied to facing materials it adds strength to a structure. For example, the ability of polyurethane foam to flow-through and adhere to the inside surfaces of a cavity, provides a continuous bond between the faces that can be considered a structural element. With its application to the underside of a roof, it can help secure tiles and offer a similar level of protection to a breather membrane; whilst also adding an insulting layer.

The adhesive bond strengths of polyurethane foams can be in the order of, or better than, 60 Kn/m2.

[edit] Producing polyurethane

Polyurethanes are in the class of compounds called 'reaction polymers', and are produced by mixing two or more isocyanates groups in the presence of a catalyst.

The properties of polyurethane can be influenced by the types of isocyanates and the polyols used to make them. These can range from tough or rigid versions, through to long, flexible segments; with different characteristics being controlled by the polyol using cross-links - the term given to a bond that links one polymer chain to another - with long chains and intermediate cross-linking making a polymer useful for foam.

[edit] Types of polyurethane spray foam

Polyurethane spray foams are categorised as either ‘open-cell’ or ‘closed-cell’; with several major differences between the two types, with advantages and disadvantages for both depending on the desired application or requirements.

[edit] Closed-cell polyurethane spray foam

- The principle advantages of closed-cell polyurethane spray foam are:

- Low thermal conductivity of down to 0.020 W/m2K.

- Low vapour permeability.

- Highly effective as an air barrier.

- Increases wall strength when used as part of a composite structure.

- Ablility to resist water.

- Ability to absorb sound - Especially bass tones.

- Medium density – typically around 32 g/m3.

[edit] Open-cell polyurethane spray foam

Open-cell polyurethane spray foam is usually found in densities ranging from 6.4 kg/m3 to 19 kg/m3. One of the advantages that these low densities provide is that they offer a more economical yield; since foam density is directly related to yield - lower density = higher yield.

Although the R-value of open-cell foams are only slightly more than half that of closed-cell foams, these products can still provide excellent thermal insulating and air barrier properties.

Open-cell polyurethane spray foam is more permeable to moisture, with perm ratings of approximately 10.0 per 100 mm thickness. However, the foam allows for a very controlled diffusion of moisture vapour whose consistency can be managed by correct specification.

Open-cell polyurethane foams are effective as a sound barrier; having about twice the acoustic resistance in normal frequency ranges as closed-cell polyurethane foams. Other characteristics of open-cell polyurethane foam include a softer, ‘spongier’ appearance, as well as lower strength and rigidity than closed-cell foam. These foams should not be relied upon to provide a structural element in the build environment, however, their other characteristics make them ideal for use in the manufacture of be-spoke insulated panels.

Principle advantages of open-cell polyurethane spray foam:

- Low thermal conductivity values of down to 0.020 W/m2K.

- Higher vapour permeability.

- Economical yield .

- Effective air barrier properties.

- Excellent sound absorption in normal noise frequency ranges.

- Low density.

[edit] Slow-rise and quick-cure polyurethane spray foams

Polyurethane spray foams are further categorised by their expansion rate and curing times once they are mixed and injected into a mould. These are known as either slow-rise or quick-cure.

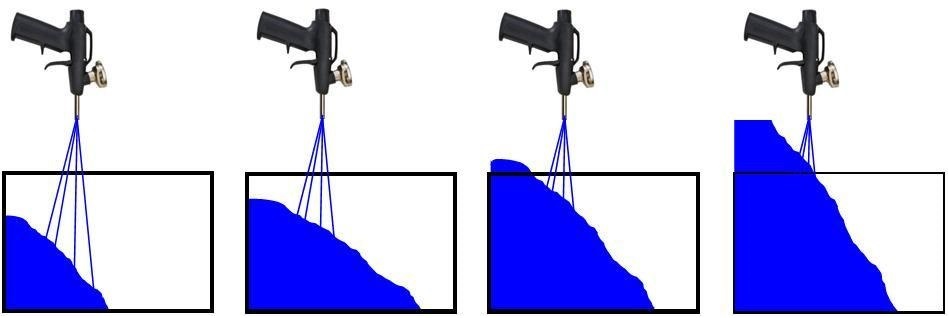

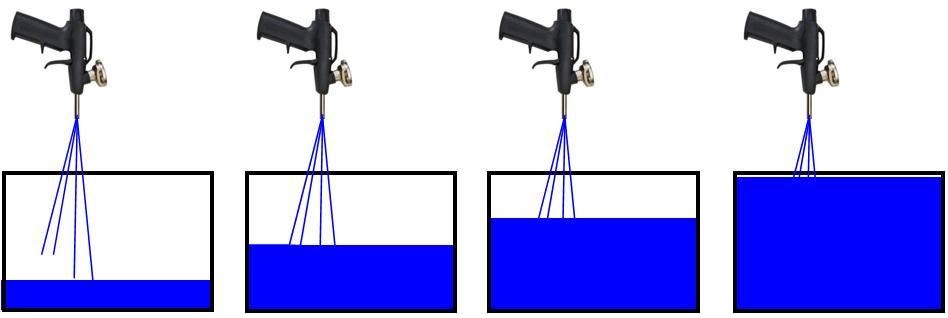

For the production of bespoke panels, slow-rise polyurethane foams should be used. This allows the foam to flow throughout the mould, filling the entire void prior to the foam curing. Quick-cure polyurethane foams, on the other hand, are primarily intended for open surface applications, being able to bond to virtually any surface and cure in seconds, due, in part, to their limited flow time.

Injecting slow-rise polyurethane spray foam into a pre-assembled panel is less time consuming and much cleaner than applying the quick-cure alternative onto an open surface. Slow-rise polyurethane foam also cuts down on wastage by reducing both the need for trimming and the mess from overspray commonly associated with quick-cure foams.

Fig. 1: The action of quick-cure polyurethane foam in a mould.

Fig. 2: The action of slow-rise polyurethane foam in a mould.

[edit] In-place density and yield

In-place density refers to the apparent cured density of the foam as it exists in its final form. This will generally be higher than the free-rise density of the foam, and will vary depending on the actual amount of foam that is dispensed into a cavity of fixed volume. In-place density is important because the final strength and physical properties of the foam will be improved and optimised by increasing the in-place density of the foam.

In-place density may be increased by dispensing a larger amount of foam into the mould than is theoretically needed to fill it, based on free-rise density calculations. This process is referred to as "packing" the foam. Proper mould venting can reduce mould pressure and help keep densities lower.

Slow-rise foam is recommended to be dispensed at an in-place density of 32 kg/m3 in order to achieve the optimum physical properties. It is possible to fill to slightly higher or lower in-place densities depending on the specific application requirements, mould strength and orientation.

Product yield is affected by in-place density, in that a higher apparent density will yield less volume of foam.

Desired in-place density X Volume of cavity = Amount of chemical required

For example: 32 kg/m3 X .057 m3 = 1.8 kg.

[edit] Mould pressure

Mould pressure is difficult to predict, however, there will be pressure exerted by any pour-in-place foam in nearly all applications and so all moulds need to be designed with stays or braced in some way. The amount of clamping required is dependent on the application and the desired in-place density. The higher the density; the higher the pressure. Pre-testing of a sample panel will give an indication of the number of stays or bracing required for a particular mould design. In general, the more foam that is put into the mould, the higher the mould pressure and subsequently, the stronger the fixturing that is required.

Three major considerations which will affect mould pressure and determine how efficiently a mould is filled are:

- Mould size.

- Orientation.

- Mould venting.

[edit] Application shot time

The term ‘shot time’ refers to the length of time necessary to dispense the desired amount of foam into the cavity or mould. Shot time can be estimated from the volume of the mould and the desired In-place density of the foam.

(Cavity size x In-place density) / Weight dispensed in one minute = Shot time in minutes.

The actual shot time will also depend on several other factors such as:

- Chemical temperature.

- Application temperature.

- Amount of chemical remaining in the system.

Accurate shot times are best determined by controlled trials and test samples.

[edit] Mould orientation and size

Mould orientation refers to the position of the mould and the direction that the foam will be poured into and rise within the mould.

There are two basic positions used to describe mould orientation:

- Horizontal pour.

- Vertical pour.

Vertical pour describes a panel that is longer in its height - or vertical direction - than its thickness. A horizontal pour is orientated where the longest dimensions are in the horizontal direction.

As a general rule, the foam does not have to work as hard when the mould is oriented horizontally, which makes this the preferred mould position in many applications. This is because the foam will need to rise a shorter distance and the cell structure will then tend to be stronger, since the foam cells are less elongated in the direction of rise.

Mould orientation is the most important consideration when determining the specific requirements for applying foam in a ‘pour-in place’ application. The best results are determined by controlled trials and testing as part of the design process.

Proper mould venting can reduce mould pressure and help keep densities lower by allowing the gasses and products to exhaust and flash. Always provide sufficient air escape holes to allow the rising foam to push out any trapped gasses as the mould is filled.

[edit] Post shrinkage or expansion prevention

All materials exhibit some expansion or contraction according to temperature changes. Polyurethane foam systems are subject to volume changes under extreme conditions due to the cellular structure and the closed cell nature of the product, in addition to the normal expansion / contraction caused by temperature differentials.

Dimensional stability tests should be carried out to insure that the foam will perform as expected. It is important to consider the various factors in the application stage that can affect the product's ultimate strength, namely the ‘in-place’ density, temperature and mould orientation.

The in-place density is a property which will greatly affect strength, since the higher the density, the higher the strength of the foam, or the more resistant the foam is to environmental changes. The in-place density may vary, but is tested at a nominal 32 kg/m3 for comparison and specification purposes. Higher in-place densities may improve physical properties but, at the same time, will reduce the cost-effectiveness of the product, as well as producing higher mould pressures and reduced flow-ability. Correspondingly, lower in-place densities may increase the likelihood of volume changes under extreme conditions.

In addition, mould orientation, which forces the foam to rise a long distance, will tend to elongate and stretch the cells, which can also weaken the ultimate strength of the foam. The appropriate ratio of chemicals is, of course, critical to achieving optimum performance and must be assured for success in any application.

[edit] Effects of temperature

Air temperature plays a critical role in the performance of any two-component polyurethane foam system. Both the liquid chemical temperature and the ambient temperature, (i.e. mould temperature), will affect system performance. The recommended chemical temperature is in the range between 24-29°C. The chemical must be stabilised within this range. If the chemicals are not within this range they may dispense in the incorrect ratio, leading to poor quality foam.

[edit] Moisture vapour transmission - perm ratings

Water in its low energy state (liquid) does not permeate through polyurethane closed cell foam. In its high energy state (vapour), its permeance is retarded significantly.

Because of its very low moisture vapour transmission properties, polyurethane foam may be considered a 'vapour retarder' when applied in sufficient thickness. There is no definition of what constitutes a vapour retarder as opposed to a vapour barrier, but the insulating and air barrier properties of polyurethane foam make it an excellent solution to condensation and humidity build-up in properly designed applications.

[edit] Related articles on Designing Buildings

- Insulation specification.

- Sandwich panel.

- BREEAM Insulation.

- Building fabric.

- Cladding.

- Composites.

- Curtain wall systems.

- Expanding foam.

- Foldcore.

- Glazing.

- Metal composite panels.

- Polyurethane (PUR).

- Rainscreen.

- Structural Insulated Panels.

- Wall types.

- Insulation.

[edit] British Standards Associated with the Insulation of Walls:

- BS 4841-1:2006 - Rigid polyisocyanurate (PIR) and polyurethane (PUR) products for building end-use applications. Specification for laminated insulation boards with auto-adhesively or separately bonded facings.

- BS 4841-2:2006 - Rigid polyisocyanurate (PIR) and polyurethane (PUR) products for building end-use applications. Specification for laminated boards with auto-adhesively bonded facings for use as thermal insulation for internal wall linings and ceilings.

- BS7456 - Stabilisation and thermal insulation of cavity walls.

- BS 7457:1994 - Specification for polyurethane (PUR) foam systems suitable for stabilisation and thermal insulation of cavity walls with masonry or concrete inner and outer leaves.

- BS 8216:1991 - Code of practice for use of sprayed lightweight mineral coatings used for thermal insulation and sound absorption in buildings.

- BS EN 12086:1997 - Thermal insulating products for building applications. Determination of water vapour transmission properties.

- BS EN 13165:2001 - Thermal insulation products for buildings. Factory made rigid polyurethane foam (PUR) products.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”