Compressed Earth Blocks as a route to meeting greenhouse gas reduction targets

There is an opportunity to significantly reduce the embodied carbon created by the building industry and help the UK meet its net zero target by 2050. As mentioned previously in the articles The Seventh Carbon Budget: what it means for the built environment and The UK Net Zero Carbon Buildings Standard: creating a true pathway to the future, the UK built environment is responsible for approximately 25% of total UK greenhouse gas emissions, and at COP29 the UK Government committed to an at least 81% reduction in greenhouse gas emissions by 2035, relative to 1990 levels.

The production of cement, the firing of bricks and the substantial amounts of transportation of these materials contributes to much of the building industries CO2 emissions, so any reduction in the use of these materials will reduce the UK’s contribution to greenhouse gases.

A method of build that could make a significant contribution to these targets is using compressed earth blocks (CEBs, with or without the addition of chopped straw) to replace much of the use of concrete blocks in low level builds such as housing and small industrial units. CEBs use waste soil (which is normally transported to landfill, at ever-increasing costs and emissions) from civil engineering projects, perhaps even from the construction site itself, and only require a small amount of CO2 emissions to mix and form before they are ready for use. Any water in the process can easily be harvested from run-off and the product is usable 2 to 4 weeks after forming.

Compared to conventional concrete block walls with common forms of insulation, CEBs are a very low carbon alternative. But CEBs are perceived as a risk because there is little data for architectural practices and construction firms to specify this alternative. There is some data and guidance for monolithic cob structures, but these do not fit with conventional construction methods and involve more time and specialist skills to construct.

For the building industry and architectural practices to take up the use of CEBs, there needs to be solid data to make it clear that it is a low-risk method of building. If conventional blocks are substituted with CEBs, only a small modification of skills and logistic timings would be required. This is because they are very similar to traditional concrete blocks and can be manufactured to the same sizes.

The current use of CEBs in builds include those made of H.G. Mathews and listed on the NBS source as ‘Strocks’: “A structural block of clay-rich earth and chopped straw. Strocks can be used as the inner skin of an external wall and for internal load-bearing walls typically up to three storeys” and have BRE and Warrington fire certification. Their strength is 2.96 N/mm² and they have listed uses, including internal load-bearing walls, high mass internal walls and new build homes.

Similar products are also produced by Heritage Cob and Lime, Mike Wye, Cornish Lime, Cob Block Sales, Lime Stuff, Westcott Sand & Aggregates, Earth Blocks UK, and others. Earth Blocks UK has also been developing machinery for the onsite production of blocks and a hybrid system to fit into the current construction industry, as shown with detail and hybridisation test build.

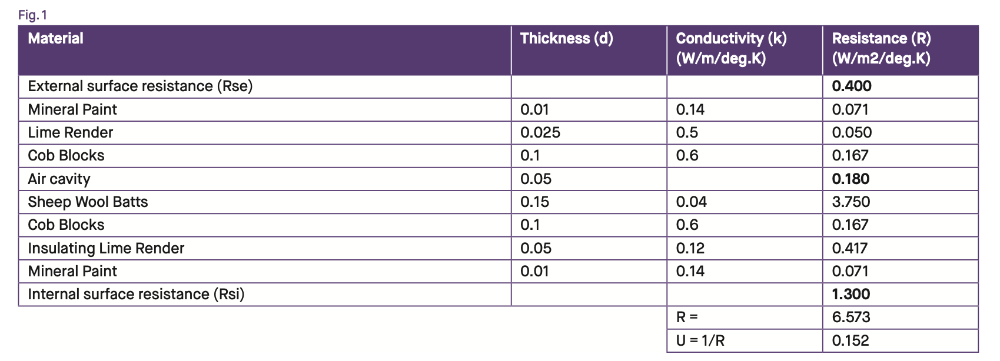

To ensure such a design meets with the requirements of Part L of the Building Regulations, U-Value calculations need to be carried out for the specific design used. An example to meet the regulations for a domestic new build could look like the table below (Fig 1).

There are currently many monolithic earthen/cob buildings in Leicestershire, Northamptonshire, Devon and Cornwall that are up to hundreds of years old, so durability of the material is not a problem. There has been research into the future of monolithic cob in the UK, mainly centred around Plymouth University. For instance, on improvement to the thermal performance of earthen walls to satisfy current build regulations and their international CobBauge project and builds, such as the CobBauge House in Fakenham, Norfolk. My own research project at Nottingham Trent University aims to study the use of CEBs in place of traditional block construction. It will also address that there is the need to understand the current attitude of the industry, the users and other stakeholders in the sector as to why CEBs are currently not more widely used. Information for increased usage include:

- Useability. Does the construction industry need to change the way its workers work to use the new materials? (Building Regulation Approved Document 7).

- Strength and durability of the materials (Build Regulations Approved Document A).

- Fire resistance (Build Regulations Approved Document B).

- Sound insulation of bricks and complementary insulation materials (Build Regulations Approved Document E).

- Storage of the materials on site.

- Thermal properties and heating and ventilation systems (Build Regulations Approved Document L).

- Cavity wall insulation, used to keep embodied carbon down and reduce VOC emissions (Build Regulations Approved Document D).

There also needs to be detail information with regards to:

- Structure and make up of walls and fixing of roofs (i.e. robust details).

- BIM information.

- Drawing/modelling (e.g. Revit families).

- Soil sampling, type of clay (for example, Illites, China clay, or Kaolinite), ranges of aggregate particle size and type adjustments, and brick pre use tests with new soils.

- Brick and block drying times to ensure they are structurally ready for building.

- It will be interesting to see whether, over the next few years, the use of CEBs increases and that the greenhouse emissions related to the construction industry fall.

This article appears in the AT Journal issue 154, summer 2025 as "Can the construction industry help the UK meet its greenhouse gas reduction targets? written by Richard Clark ACIAT BSc (Hons) BA (Hons) BTEC HND Mech Eng".

--CIAT

[edit] Related articles on Designing Buildings

- Adobe.

- Clay.

- Cob building.

- Compressed Earth Blocks CEBs.

- Construction materials.

- Daub.

- Do green buildings pay?

- Earthen construction.

- Earth building.

- Green building.

- Shelter.

- Straw bale construction.

- Sustainable materials.

- Unfired clay masonry: An introduction to low-impact building materials.

- Vernacular earthen architecture.

- Wattle and daub.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.