Groundwater control in urban areas

Contents |

[edit] Introduction

Excavation works for underground infrastructure such as deep basements or tunnels often encounter groundwater. Working below groundwater level can be difficult, as the excavation is at risk of instability and inundation. However, modern geotechnical techniques can allow groundwater to be safely managed.

[edit] Underground infrastructure in cities

In cities, space is at a premium. Increasingly, new infrastructure requires work below ground for deep basements, tunnels and other underground spaces. In London, Crossrail is a prime example of how new infrastructure is using below-ground engineering skills to fit new infrastructure beneath and around all the existing paraphernalia of a bustling city.

Civil engineering underground often hits a poorly understood but very real problem – groundwater. This is an especial problem when excavating in water-bearing soil (such as sands and gravels) or fissured rock (such as chalk or sandstone). Without suitable control measures, inflows of groundwater can flood excavations or tunnels, and can also lead to instability when the soils or rock around the excavation weaken and collapse – either locally or on a large scale.

Over the last few decades there have been several high-profile projects around the world that have been seriously delayed by groundwater problems. On the other hand, a much greater number of projects have successfully dealt with groundwater with no obvious problems. In the south of England, projects like High Speed 1 (known as the Channel Tunnel Rail Link during its construction in the early 2000s) and Crossrail have routes which successfully passed through multiple water-bearing strata, including crossing beneath the River Thames.

The secret is – not that it is a secret to geotechnical engineers – that there are several construction techniques that can be used to control groundwater.

[edit] How do civil engineers deal with groundwater?

The first thing that needs to be done to ensure that groundwater can be effectively dealt with is to gather information to understand the problem. This involves a site investigation, which might involve drilling and testing of boreholes, measurement of groundwater levels and tests to measure the permeability of the ground. Permeability is a measure of how easily water flows through soils or rocks. High permeability soils and rocks tend to be water-bearing and are typical of the conditions where groundwater can cause problems for construction projects.

The techniques used to control groundwater include:

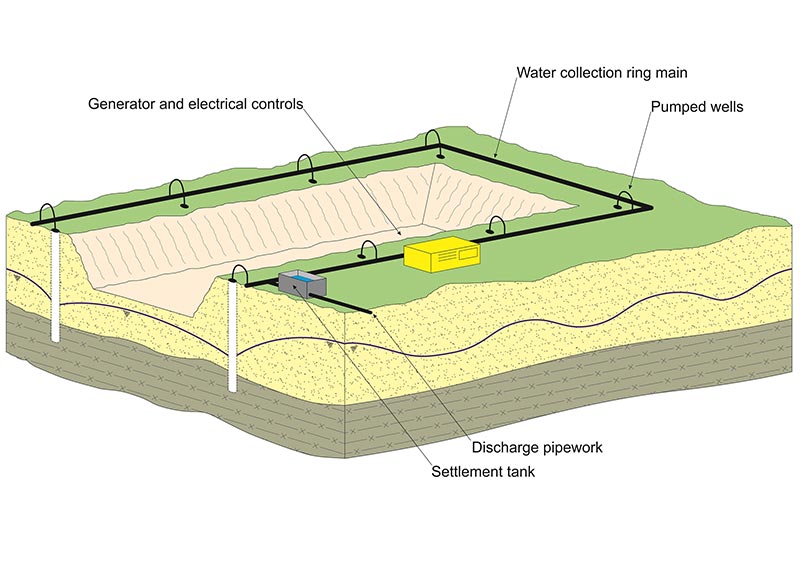

[edit] Groundwater pumping

Also known as ‘dewatering’, this approach involves pumping groundwater from an array of wells or sumps around the excavation. The objective is to lower groundwater levels to below working level in the excavation. Examples of this group of techniques include sump pumping, wellpoints, deepwells and ejector wells.

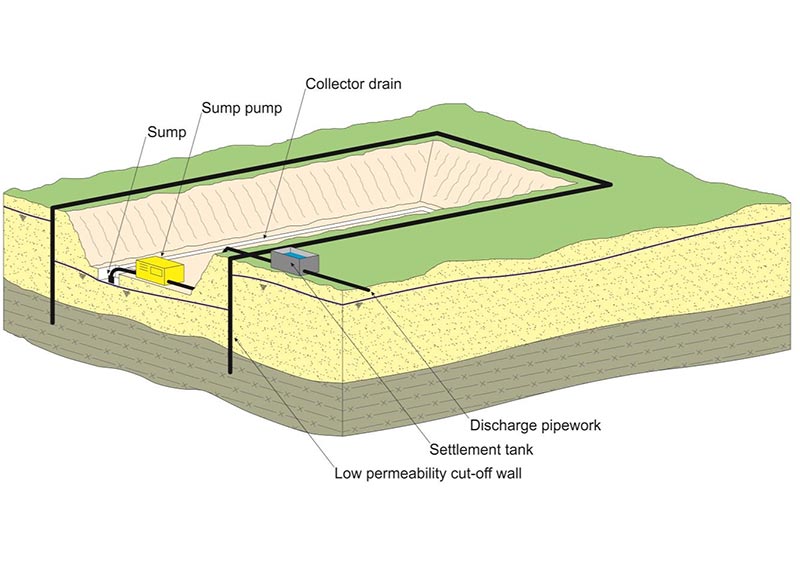

[edit] Low permeability cut-off walls

In this approach, low permeability barriers (known as 'cut-off walls') are installed into the ground around the perimeter of the excavation. These walls act as barriers to groundwater flow, and effectively exclude groundwater from the excavation. The requirement to pump groundwater is limited to pumping out of the water trapped within the area enclosed by the cut-off walls. Examples of the techniques used to form cut-off walls include steel sheet-piling, concrete diaphragm walls, concrete bored piles and bentonite slurry walls.

[edit] Grout barriers

This involves the injection into the ground of fluid grouts that set or solidify in the soil pores and rock fissures. The grout blocks the pathways for groundwater flow and can produce a continuous zone of treated soil or rock around the excavation that is of lower permeability than the native material. This reduces groundwater inflow in a similar way to cut-off walls. The most commonly used grouts are based on suspensions of cement in water.

[edit] Artificial ground freezing

In this technique, a very low temperature refrigerant (either calcium chloride brine or liquid nitrogen) is circulated through a series of closely-spaced boreholes drilled into the ground. The ground around the boreholes is chilled and ultimately frozen. Frozen soil or rock has a very low permeability, and will significantly reduce groundwater inflow into any excavation.

For more information, see Freezing method.

Each of these approaches to groundwater control has different advantages and disadvantages, and is applicable only to certain soil or rock types. Selection of suitable groundwater control measures is one of the key aspects of the design of underground works.

This article originally appeared as ‘Groundwater control in urban areas’, published by the Institution of Civil Engineers on 3 February 2016. It was written by Dr. Martin Preene of the British Geotechnical Association.

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings

- Articles by ICE on Designing Buildings Wiki.

- BREEAM Surface water run-off.

- Biological fouling.

- Bund.

- Caisson.

- Chalk aquifer.

- Cofferdam.

- Culvert.

- Dam construction.

- Detention pond.

- Dewatering.

- Drainage.

- Drainage and sewerage management plans DSMPs.

- Eutrophication.

- Fertilizer groundwater pollution.

- Flood.

- Groundwater.

- Groundwater control.

- Gully.

- Highway drainage.

- Hydrogeology.

- Inflow.

- Pumps and dewatering equipment.

- Reservoir construction.

- River engineering.

- Sinkholes.

- Soakaway.

- Sump pump.

- Surface drainage.

- Sustainable water.

- Sustainable urban drainage systems SUDS.

- Swales.

- Types of water.

- Water engineering.

- Water management.

- Water table.

- Water transfers and interconnections.

Featured articles and news

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.