Ground energy options

Contents |

[edit] Introduction

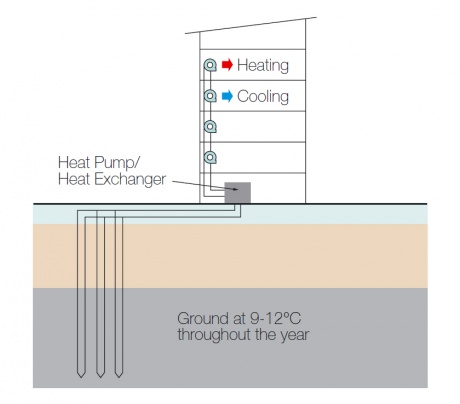

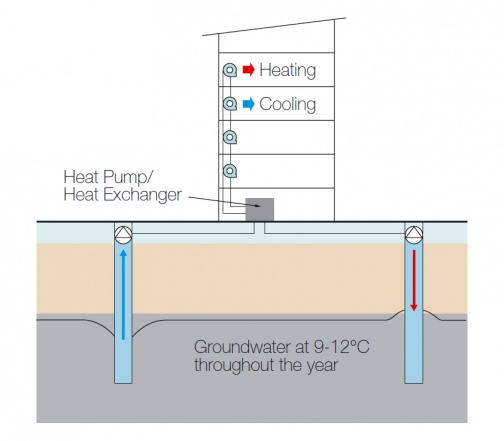

Below a depth of approximately 6m, the temperature of undisturbed ground remains fairly constant at the mean annual air temperature throughout the year. Depending on the location and depth this temperature is typically between 9 and 12ºC in the UK. This means that the ground can be used to as a heat source in the winter and as a source of coolth in the summer.

In general, the use of ground energy to provide heating and cooling in buildings requires equipment (heat pumps). The energy can be transferred to this equipment using a ground heat exchanger (closed loop system). This usually comprises a number of pipe loops, vertical or horizontal, with a primary process medium of water, or more normally a glycol solution which eliminates the possibility of freezing at the lower end of the application’s seasonal temperature range. An alternative system is to abstract and discharge ground water (open loop systems) from an aquifer beneath the building.

In the case of the closed loop system, the energy in the ground is (if the ground loop is sized appropriately) replenished by solar irradiation, rain and, sometimes, for deeper vertical collector systems, underground water flow. With open loop systems it is necessary to consider the sustainable yield available from the wells.

[edit] Variations of ground energy

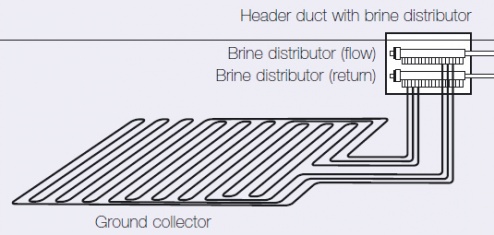

[edit] Horizontal – closed loop

With this variation, the energy or heat is transferred to the building using a series of ground collectors, laid horizontally at a depth of 1.5-2m. Each pipe run should be limited to 100m to avoid the need for more powerful circulation pumps. Pipe runs would normally be the same length to guarantee similar flow conditions, pressure drops and to ensure an even heat extraction from the ground.

The useable amount of heat or energy is dependent on the following:

- Solar irradiation for the specific area.

- Moisture content.

- Soil type.

- Size of pores.

Extraction rates are generally in the order of 10 W/m2 for dry sandy soil, to over 30 W/m2 for wetter loamy soils. Relatively inexpensive earth moving equipment is required for installation, although costs increase with greater depths. This type of collector is generally used for applications with lower power outputs where there is a large undeveloped area that is easy to excavate.

[edit] Vertical (probe) – closed loop

A vertical closed-loop system utilises vertical ground heat exchangers or probes that are inserted into specially drilled boreholes up to depths of 150m.

Extraction rates generally vary between 20 W/m for loose dry substrate to ~80W/m for damper sandstones, granites and basalts.

The useable heat or energy is dependent on similar factors to the horizontal system although more specialist geological analysis is generally needed. Deeper test-bores can ascertain the type and depth of each soil/rock layer, the heat transfer potential for the different layers over the length of the borehole, the presence and height of water table and underground water flow.

Due to the requirement for a test bore, this type of system lends itself to larger applications where the initial testing costs can be justified. The data gathered helps to reduce risk during the design stage as non-optimum sizing has serious cost implications.

[edit] Vertical – open loop

In this variation, ground water is extracted direct from the underground water aquifer, eliminating the need for a closed loop ground heat exchanger. The used cooled or heated water can then be returned to the ground via a return well.

Prior to the consideration of such a configuration, it is necessary to contact the Environmental Agency, initially to gain consent for a pumping test, then for a final abstraction licence for a pumping test, and finally for discharge consent. There is an additional requirement to consider the water quality of the water source, as this can have an adverse effect on the materials used within the heat exchanger.

[edit] Feasibility and Evaluation

[edit] Generic guidelines for ground energy systems

[edit] Start considering the technology at an early stage in the project.

- Complete a ground energy desktop survey to establish the suitability of the geology and hydrogeology underneath the site to different types of ground energy systems. Suitable sources include the British Geological Survey and site specific Geotechnical Investigation reports.

- Establish the spatial limitations around the building.

- What is the indicative foundation design and is it suitable to act as part of the ground energy heat exchanger?

[edit] Optimise the heating and cooling building circuits.

- Use high temperature cooling where possible (eg chilled beams and air based systems with over sized heat exchangers).

- Use low temperature heat emitters (large radiators, underfloor heating and air based systems with oversized heat exchangers).

- Simultaneous heating and cooling can be provided from the same heat pump unit.

[edit] Closed loop do’s

- For larger commercial systems, ie greater than ~100kW, a thermal conductivity test is advisable to confirm the insitu thermal properties.

- Carry out a desktop simulation using recognised software to ensure long-term performance can be guaranteed.

- Ensure boreholes are spaced adequately to reduce thermal interference.

- Try to balance heat abstraction and rejection to the ground.

- Consider using less expensive conventional plant for infrequent heating and cooling loads and/or higher relative seasonal heating and cooling loads.

[edit] Open loop do’s

- For almost all open loop systems, Environment Agency (EA) approval is needed for both abstraction and discharge of ground or surface water.

- A pumping test will be needed to confirm the yield and to get permission from the EA to abstract and discharge a specified volume of water per hour/day/year.

- Start the process to obtain an abstraction licence and discharge consent as early as possible, as this process can take eight to nine months in the UK.

This article was created by --Buro Happold, 17 March 2013, based on a 2008 article in 'Patterns'.

[edit] Related articles on Designing Buildings Wiki

- Dynamic thermal modelling of closed loop geothermal heat pump systems.

- Earth-to-air heat exchangers.

- Environmental performance.

- Geothermal energy.

- Geothermal pile foundations.

- Ground preconditioning of supply air.

- Ground source heat pumps.

- Heat gain.

- Heat pumps.

- Ring circuit.

- Thermal labyrinths.

- Water source heat map.

- Water source heat pump.

[edit] External references

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.