Tensile structures

[edit] What is a tensile structure ?

A tensile structure is a structure that is stabilised by tension rather than compression. The tension can be in one linear direction via cables or rods, such as with a suspension bridge or in a number of linear directions via the same such is found in tensegrity structural systems. Today possible the most common known form of tensile structures are fabric such as canopies where a piece of fabric is pulled in one or many opposite directions.

Conventional structures tend to be stabilised by the action of gravity on their mass holding them in compression whilst tensile structures are stabilised by tension rather than compression as shown below.

|

|

| Compression structure | Tensile structure |

In practice, structures tend to carry both tension and compression, and it is the degree to which a structure is intentionally tensioned to stabilise it that determines whether it is considered a tensile structure.

Tensioning, is usually achieved with wire or cable, opposed by compression elements such as masts, and held in place by foundations, ring beams, ground anchors and so on. Tensioning can also be achieved through inflation and some gridshell structures, might be considered to act in tension (but not all), even timber structures using more flexble green oak have been erected and fixed in tension.

Structures with tension elements generally include:

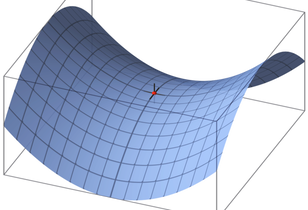

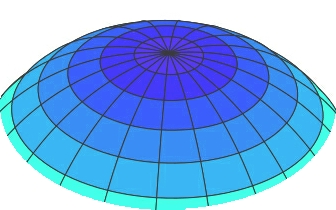

Three-dimensional tensile structures typically form doubly-curved shapes that are either anticlastic or synclastic.

|

|

| Anticlastic (saddle-shaped). | Synclastic (dome-shaped) |

Doubly-curved surfaces can be tensioned without distorting their form, as the opposing curvatures balance each other at every point on the surface. Tensioning the fabric reduces its elasticity so that it will distort less when subsequently loaded, such as under wind load or snow load. In addition, the geometry of the curvature itself means that any extension of the fabric under load results in a relatively smaller deflection than would be apparent in a flatter, or less curved fabric.

So the greater the curvature and the greater the pre-tensioning of the fabric, the less it will distort under load.

For more on the structural behaviour, see The structural behaviour of architectural fabric structures.

Typically, tensile structures use less material than conventional compression structures and, as a result, are lighter and can span larger distances.

[edit] Architectural examples of tensile structures

Frei Otto is possibly most associated with tensile structures, in particular the German Pavilion built for the Montreal Expo in Canada of 1967 (the same exhibition included the Buckminster Fuller Biosphere geodesic dome), in 1972 the architect built the huge plexi glass clad cable net structure of the Munich Olympic Stadium. This was a significantly scaled and permenant construction containing 271 miles of steel cabling, attached to fifty-eight cast steel pylons, which supported a curving roof canopy that covered almost 75,000 square meters. Other projects that may be considered as tensile gridhshells come from his collaboration with Shigeru Ban on the Japanese Pavilion at Expo building in 2000.

Millennium Dome (known as 'the Dome') is a fabric clad, cable net structure in Greenwich, London that was opened in 2000 as the centrepiece of the UK’s millennium celebrations, which ran from 31 December 1999 to 31 December 2000. It was designed by the Architect’s Richard Rogers (now Rogers Stirk Harbour + Partners) with engineers Buro Happold as simple proposed the idea of covering the site with a large fabric dome, to create the shelter for a year long celebration that would open and close in the winter. The Dome is neither a true dome, nor a conventional fabric structure, but a cable net structure, clad with flat PTFE coated glass fibre fabric panels with two layers to provide insulative qualities.

[edit] Related articles on Designing Buildings

- Air-supported structure.

- Anticlastic.

- Cable.

- Catenary.

- Concept structural design of buildings.

- Conoid shell.

- ETFE.

- Fabric structures.

- Hyperbolic paraboloid.

- Inflatable building.

- Long span roof.

- Megastructure.

- PTFE.

- Shell roof.

- Stretched-skin ceiling.

- Structural membrane.

- Synclastic.

- Tensegrity.

- Tensegrity bamboo pavilion.

- Tensile strength.

- The development of structural membranes.

- The structural behaviour of architectural fabric structures.

- Thermal behaviour of architectural fabric structures.

- Types of dome.

Featured articles and news

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this.

Comments