King post

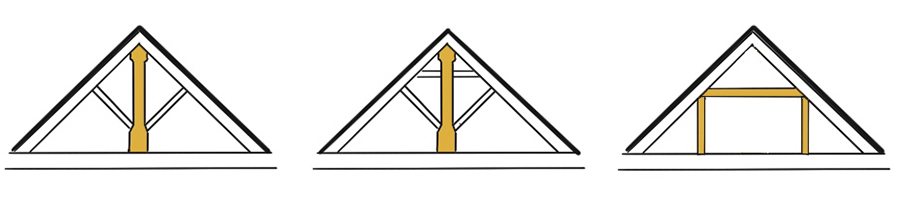

King post is a term used to describe structural elements that rely on a single or key structural member, particularly in traditional timber framing. The term is commonly used in timber and steel structural design to describe a king post truss (other variations of a king strut truss and queen post truss are shown above).

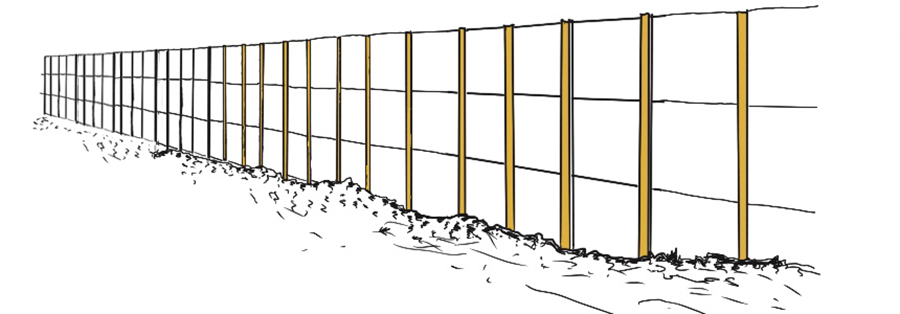

It is also used to describe a type of wall construction. King post walls are often used in below ground foundation or retaining wall design, also referred to as king piles or soldier piles, with a series of posts with infill between, see image below.

The term king closer (or closure) is a type of cant brick used in a bricklaying technique to finish internal corners. A queen closer similarly is a cut brick or brick bat. The term king, may also be used to describe oversized building elements such king size bricks, blocks or beams as well as other items such as beds. It is also used in the phrase king pin, which is most commonly associated with automobile engineering but also a specific connection of a bicycle frame.

[edit] King post truss

A king post truss comprises a single horizontal tie beam, a pair of principal rafters and the central vertical king post into which the principal rafters are jointed at the apex (see above). The top of the king post acts like a key stone in a masonry arch, with the bottom of the post supporting the middle of the tie beam, rather than bearing on it. This helps achieve greater spans with smaller timber sections. Struts lie at angles between the middle of the post and the principal rafters, which in turn are supported at the top by a ridge beam which is also joined to the king post.

A king strut is part of a very similar truss with the only difference being a horizontal cross beam at its top end connecting to the rafters. A queen post truss is similar but has two posts spaced at the centre of the truss with a cross beam creating a square frame above the tie beam and no central post.

[edit] King post wall

King post walls contain main columns (king posts or soldiers) installed in equal spaces at a few metre centres along a construction line. The space between is filled with concrete panels, blocks, brick or stone and acts as a retaining wall (see above). Specification for king post walls can be found in the British standards or Eurocode 7 for temporary or permanent conditions and it is a common construction method.

Generally the king posts are driven into the ground, thus are also referred to as king piles, and connected with a beam, to form H shapes, as such one might refer to the lower half as king piles and the upper half as king posts. The upper part of the H structure is normally then in filled with precast concrete panels and may sit above ground.

One infamous example of this kind of wall design was employed in the earlier construction of the Berlin wall (which is also sometime used to describe this type of construction method). The posts or soldiers being driven into the ground and then the concrete reinforced panels infilling the gaps between creating the above ground wall, which was later supplemented by the free standing concrete panel wall system more readily associated with the Berlin wall.

The same design approach may also be entirely back filled and located underground for the construction of retaining walls, often referred to as king post piles, or pile walls, soldier walls or just retaining walls.

[edit] Related articles on Designing Buildings

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Comments

To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.