Timber roof

Contents |

[edit] Introduction

Timber has been the traditional material for building roofs as far back as early Saxon times and beyond. It is still the roof material of choice for housebuilders and self-builders, irrespective of whether they are building in traditional or contemporary styles, or whether they are creating pitched or flat roofs.

The popularity of timber as a roofing material is because it has been hitherto widely available, is generally light and easy to work with, has an excellent strength-to-weight ratio, can be an economic choice, usually has pleasing looks and can be an environmentally-friendly option when sustainably sourced. It is also bio-degradable.

Historically, timber was the most abundant and suitable material from which to build the roof structure. The roof covering was the dominant factor in determining the form of the roof. This would be almost invariably pitched, ie sloping, usually from a central ridge. The degree of pitch was determined by the roof covering (small elements necessitate a steeper pitch than say lead sheeting due to the greater chance of rain ingress through the many gaps) and the level of exposure. Typically, thatch required a pitch of around 50° degrees, plain clay tiles 45°, and thick slates and stone flags a minimum 35° pitch; lead, copper and zinc sheet can be laid at very shallow, almost flat, slopes.

The roof covering (carried on laths usually) not only dictated the roof pitch, but also the size of the timbers: stone slates (used for wealthier houses) were extremely heavy compared to clay roof tiles or thatch, and required very sturdy posts and strong rafters.

[edit] Structure

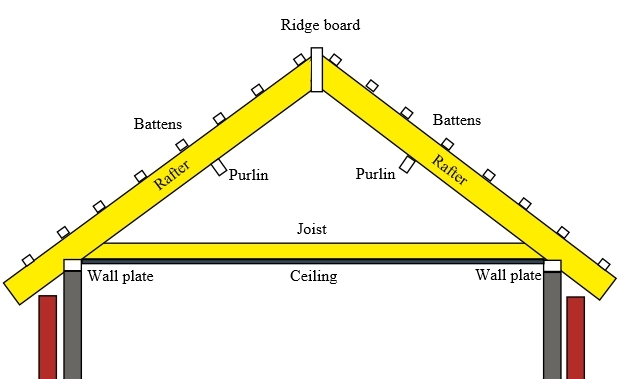

There are two basic components of a timber roof: the supporting structure and the covering.

For homebuilders, a timber frame for a flat roof is usually the cheapest option and the easiest to build. But this type of roof is seldom as attractive as the pitched form as it can result in a blocky, stunted appearance. Finishes for flat roofs are also more limited. Furthermore, there is no loft space in a flat roof for water tanks and storage and, unlike the pitched roof, water is not ‘shed’ off. Leaks are also harder to find.

In a simple pitched timber roof, the horizontal timber members (beams) called purlins support the sloping secondary timber members (rafters); purlins run parallel to the roof ridge. To prevent a roof being blown off by the wind, the rafters are usually notched with a ‘birdsmouth’ to fit over the purlins. With masonry wall supports, the rafters are usually notched over a timber wall plate that is fixed to the top of the brickwork or blockwork. They are usually tied down with galvanised mild steel straps. In timber frame construction, rafters are typically notched at the eaves over a purlin that is bolted to timber posts.

It should be noted that although principles governing the structural members forming the roof may be broadly similar, there can be considerable differences in terms of size, arrangement and jointing methods.

[edit] Roof trusses

To span large distances (that is the distance between the supports to the roof construction), rafters can be formed into triangular structures called trusses. This is achieved by connecting the lower ends of rafters at the eaves with a timber beam, thereby forming a triangle. The timber beam ties together the rafters and prevents them splaying.

Rather than creating this arrangement on-site from individual timber lengths (which is the traditional method and is easily done although more time consuming and may result in oversized timbers), modern construction offers the prefabricated timber truss.

For simple spans without internal supporting walls, timber trussed rafters can be an economical choice. They are the result of many years’ accumulated knowledge into triangulated roof structures.

Modern trussed rafters built in a factory environment offer the following benefits:

- Made from stress-graded timbers;

- Joined accurately under factory conditions using mild-steel truss plates;

- Can span large distances;

- Light;

- Economical;

- Can be delivered to site at the right time in the project programme, and

- Minimal handling as they are hoisted in position.

Trussed rafters are typically spaced at 600mm centres and provide support for the roof covering material and the ceiling below. Despite the structural efficiency of the timber roof truss, diagonal wind bracing is still required, usually running from a bottom corner to a top corner.

Any design for a timber roof, whether traditionally built or using roof trusses or modern methods of construction, should be verified that it is fit for purpose by a qualified structural engineer.

[edit] Related articles on Designing Buildings Wiki

- Closed couple roof

- Cold roof

- Collar roof

- Couple roof

- Crow-stepped gable

- Domestic roof

- Domestic roofing

- Flat roof.

- Long span roof.

- Mansard roof.

- Mono pitch roof.

- Pitched roof.

- Purlin roof.

- Rafter.

- Thatch roofing.

- Truss.

- Carpentry.

- Cross-laminated timber.

- Glulam.

- Hardwood.

- In-situ reinforcement of timber beams.

- Laminated veneer lumber LVL.

- Modified wood.

- Nails - a brief history.

- Physical Properties of Wood.

- Plywood.

- Softwood.

- Sustainable timber.

- Timber frame.

- Timber preservation.

- Types of timber.

Featured articles and news

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

Comments