Roof tiles

Contents |

[edit] Introduction

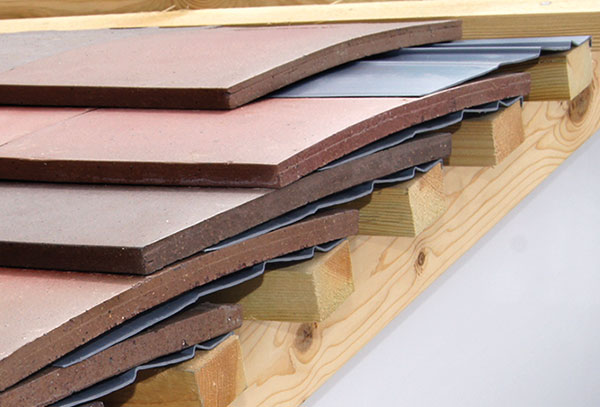

The two main kinds of roof tile used in the UK are plain tiles and interlocking tiles.

Roof slates are often mistakenly referred to as 'tiles' and vice versa. Roof slates, as the name suggests are made from slate.

BS5534 is the code of practice for slating and tiling, including shingles, for pitched roofs and vertical tiling.

[edit] Plain tiles

Plain tiles have been used for hundreds of years with the earliest examples being hand-made. Traditionally, they were made from clay, although concrete has also been used since the 1950s.

They are a simple rectangular shape and fairly small in size, commonly 265 x 165 mm. Plain tiles have to be laid double lapped, which means there have to be two layers of tile throughout the roof and at the end laps of the tiles the top tile must overlap the tile two below it. Due to the double lapping and the small size of these tiles, they can be relatively expensive, slow to lay and roofs can be heavy.

[edit] Interlocking tiles

Interlocking tiles overlap and interlock at their sides and so can be laid single lap. Traditional examples include clay pantiles and roman tiles, although since the 1970's the majority have been manufactured from concrete. They are commonly around 420 x 300 mm and can be laid to angles as low as 15°. Due to their large size and single lap, they are relatively inexpensive, quick to lay and weigh around 50-60% that of a plain tile covering.

[edit] Double lap tiling

Double lap tiling is the traditional covering for pitched roofs, mainly using plain tiles. Each tile has at least two nibs on the underside of its head so it can be hung on support battons that are nailed over the rafters. Generally, unless the roof exposure is high, only every fourth course of tiles is nailed. Double lap tiles are laid to a bond so that the edge joints between the tiles are in the centre of the tiles immediately below and above.

Typical double lap tiles include:

- Standard plain tile: 265 x 165 mm

- Eaves or top course tile: 190 x 165 mm

- Tile-and-a-half tile: 265 x 248 mm

- Half-round ridge tile: 300 or 450 x 200 mm

- Curved valley tile.

- Bonnet hip tile.

[edit] Single lap tiling

A single lap of one tile over another is sufficient to provide the weather tightness required. Most single lap tiles have a tongue-and-groove joint along the side edges to form a series of interlocking joints. There is a reduction in weight of the overall roof covering compared to double lap tiling, but the batton size will be larger. Single lap tiles should be mechanically fixed with either a clip or nail.

Typical single lap tiles include:

Roll type tile

- Minimum pitch: 30-degrees.

- Head lap: 75 mm.

- Side lap: 30 mm.

- Gauge: 343 mm.

- Linear coverage: 300 mm.

Trough type tile

- Minimum pitch: 15-degrees.

- Head lap: 75 mm.

- Side lap: 38 mm.

- Gauge: 338 mm.

- Linear coverage: 292 mm.

[edit] Repair and replacement

To minimise the risk of damage during the inspection of roof tiles a number of precautionary techniques may be employed:

- Crawling boards for roof access.

- Roof ladders suitably packed to prevent damage to the roof covering.

- Use of access platforms.

Individual tiles that are damaged during or after installation should be replaced as soon as possible. In some cases, this may require stripping back a large area of tiling, and sometimes the most practical option may be the complete re-tiling of the roof. Superficial coatings, adhesives or other mechanical repairs are generally not appropriate substitutes for replacing damaged tiles.

[edit] Replacing interlocking tiles

An unfixed tile can be removed using a trowel and timber wedges to ease it up slightly, so that it can slide out without the nibs getting caught on the top of the batton. Using the same procedure, the replacement tile can be inserted.

A fixed tile can be removed by lifting the tiles around it to expose the nail/s. These can be removed using a slate ripper or hacksaw blade. The replacement tile is inserted using the same procedure and re-fixed to the adjacent fixed tiles using an epoxy resin adhesive.

A clipped tile can be removed by prising off the interlock and extracting the nail. A new clip and nail can be fitted, allowing the clip to rest in the clip recess of the adjacent tile. If a number of damaged tiles are clipped, it may be necessary to strip the roof back to the nearest verge or valley/hip in order to re-clip the replacement tiles.

[edit] Replacing plain tiles

The damaged tile can be removed by raising the tiles around it using a timber wedge, and sliding the tile out. A replacement tile is positioned using the same technique in reverse, with nails or a dab of mastic placed on the underside if necessary.

[edit] Related articles on Designing Buildings

- Battens.

- Ceiling tiles.

- Ceramic tiles.

- Domestic roofs.

- Flashing.

- Flat roof defects.

- Metal profile cladding.

- Metal roofing.

- Nails - a brief history.

- Photocatalytic tiles.

- Pitched roof.

- Roof coverings.

- Roof insulation.

- Roof slates.

- Roofing defects.

- Shingle roofing.

- Thatch roofing.

- Tiles.

- Types of nails.

- Types of roof.

- Weatherboarding.

[edit] External resources

- Building Construction Handbook (6th ed.), CHUDLEY, R., GREENO, R., Butterworth-Heinemann (2006)

Featured articles and news

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.