Reaching new heights in the design of fire-safe tall buildings

Contents |

[edit] Introduction

The need to create resilient buildings using non-combustible materials has seen traditional products in the form of brickwork increasingly replace rain screen cladding in buildings more than 18m-high. It remains essential, however, that these materials meet industry safety regulations. This article looks at a brick on soffit system that has been designed to create deep reveals and brick soffits on tall masonry structures, and which meets the need for non-combustible materials thus enabling designers to realise their designs without compromise.

[edit] Brick usage

Although the origins of brickwork date back thousands of years – including the UK’s much loved red brick – brickwork as we know it today became popular around the time of the Industrial Revolution, where the mechanised production of brick increased availability and demand for this building material.

Brick has been used and specified by designers across many generations, mainly because of its consistent shape, compressive strength and ability to absorb water. Houses or residential buildings made from brick can cost less in the long-run, as lower amounts of energy are required for heating. It is no surprise that some of the world’s greatest structures are made from brick; in fact, the Empire State Building in New York is reported to have been made from around 10 million of these small but mighty building materials.

Architecturally, the intricate detailing that brickwork enables is like no other. Depending on the type of project, different bond patterns can be used. Brick detail in the form of brick soffits, deep reveals and flying beams continually make for stunning exteriors, enabling designers to create truly unique façades.

Brick has been around for centuries, and whilst trends towards other materials come and go, our love affair with it continues. Over the past decade, brick has been competing with other solutions including rain screen cladding. However, it is seeing something of a resurgence, partly due to the realisation that bricks offer a more robust and fire-resistant solution than some other forms of façade material. With this comes the need to adapt to changes in regulations, to ensure that brick is still the choice for buildings of all shapes, sizes and heights.

[edit] A change of direction

Changes to Building Regulations Approved Document B restricted the usage of non-combustible materials in buildings over 18m-high, and this has led to the exclusion of certain products. This was largely driven by the need to ensure rain screen cladding façades on tall buildings are resistant to fire so there will not be a repeat of the tragic Grenfell fire.

The questions and concerns over a number of rain screen cladding façades therefore, have seen designers move back to more traditional, tried-and-tested materials such as brick. Designers are experiencing for themselves waves of clients wanting to emulate modern interpretations of classic architecture. Brick has long been the go-to material in the UK, but the modern cladding system became a quick and cost-effective way to create bright and modern looking buildings. However, it came at a cost, with many buildings now seeing cladding systems replaced due to non-conformity to regulations and issues around fire performance.

This cost is further compounded by the ailing appearance of various modern cladding systems; they can look tired and dated over time. There can be no denying however, that many brick façades look equally as impressive today as they did when they were created decades ago.

[edit] New innovations

There has been much debate within the construction sector as to how the industry could respond to regulatory changes and have an A1-fire rated (non-combustible) or an A2-fire rated (limited combustibility) solution to provide to the market.

IG Masonry Support was challenged to develop a solution for their brick on soffit system. To fulfil this challenge, the company developed its own A1 fire-rated adhesive to meet its specific requirements. It was then independently tested. This non-combustible adhesive could be used both as a bedding compound as well as a bonding agent.

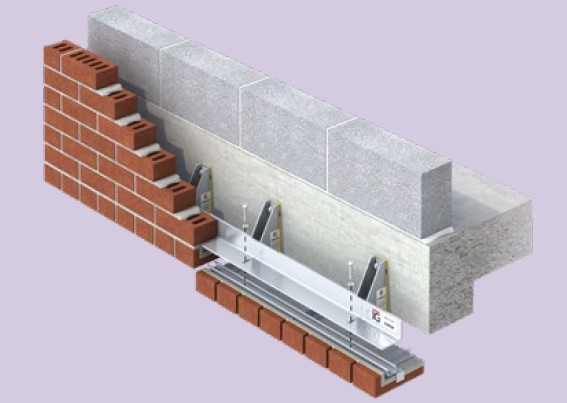

This development enabled IG Masonry Support to engineer B.O.S.S.+, an A2 fire-rated system suitable for use on projects that require Building Regulations Document B compliance. The second generation of IG Masonry Support’s B.O.S.S. system, B.O.S.S.+ comprises a stainless-steel framework with a cement particle board backing element to which the brick slips are adhesively bonded and mechanically fixed. In short, the solution ticked the boxes in all the required areas and was available to the market in 2019.

The next step was to create a fully non-combustible and carbon neutral product. The BBA Certified B.O.S.S. A1 system is A1 fire rated and has been subjected to hygrothermal testing, the product passed the rigorous examination with ease. As well as meeting current fire regulations regardless of the building’s height or purpose, the manufacturing process and environmental impacts will be significantly reduced.

|

Like the rest of the B.O.S.S. range, it is factory produced to ensure quality; once onsite, it is fixed to IG’s Welded Masonry Support (WMS). Thanks to its ingenious design, it can be adjusted onsite to ensure a perfect fit, providing brickwork contractors with a safe and efficient way of creating detailing. Installation can be reduced by up to 90% and as it is on average 70% lighter than concrete, it negates the need for mechanical lifting in many instances.

Its impressive credentials, all of which are BBA certified, offer a technically advanced solution that meets even the boldest aesthetics, by hiding structural steelwork to give the illusion of unsupported brickwork. To further ensure a quality installation, the brick slips are created using a consignment of bricks from the site to guarantee a perfect match. The unit is pointed onsite to provide a seamless integration with the surrounding brickwork.

B.O.S.S. is an established and successful product with a proven track record of success. The A1 solution is the third generation of its type within the range. Its latest incarnation provides further evidence of IG Masonry Support’s commitment to enhance and offer solutions which are tested above what is expected in the industry, whilst taking a responsible approach to climate change.

As designers know all too well some trends come and go, yet brickwork design has always been a constant. It goes without saying that brickwork gives designers great possibility in terms of design and visual aesthetics. The legislative changes that the industry witnessed last year has inspired construction supply chains to be better, and perhaps serves as a reminder of the quality and assurance traditional materials offer.

This article originally appeared in the Architectural Technology Journal (at) issue 137 published by CIAT in spring 2021. It was written by Scott Denham, Sales Director, IG Masonry Support.

--CIAT

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”