Identifying the causes of trends in construction labour productivity

This article originally appeared in BSRIA’s Delta T Magazine, published in January 2016. It was written by Lee Bryer (CITB), James Hastings (Experian), Doug Forbes (WLC Ltd) and Malcolm Horner (WLC Ltd).

Contents |

[edit] Introduction

The Construction Industry Training Board (CITB) use two tools to predict labour demand in the construction industry:

- The Construction Skills Network (CSN)

- The Labour Forecasting Tool (LFT).

The CSN works at the National and Regional level, whilst the LFT can work at a more local level. Both need to consider the impact of changes in productivity on labour demand. In addition, CITB wish to understand the role they might play in improving productivity in the construction industry.

This article describes work undertaken by Whole Life Consultants Ltd (WLC Ltd) to identify the trends in productivity, what their causes might be, and what action needs to be taken if productivity is to be improved.

[edit] Methodological approach

There were three strands to our approach:

- Literature review.

- Analysis of data available (under special licence) from the Office for National Statistics (ONS).

- Review of the results by an expert panel of distinguished practising professionals and academics.

[edit] Trends

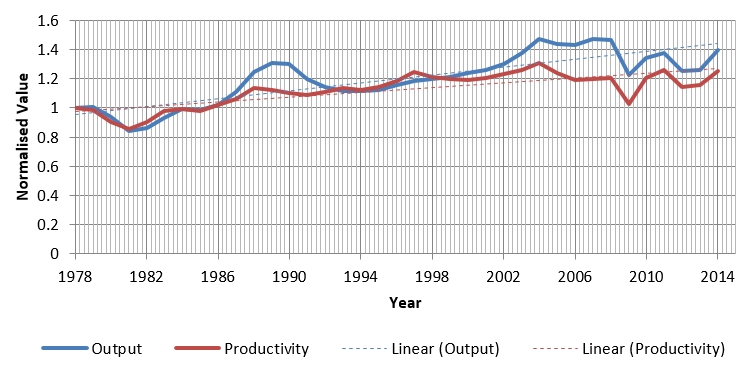

Figure 1 shows total construction output in constant 2005 prices and productivity expressed as output per hour worked, both normalised to 1978 values, the first year for which consistent statistics are available. In each case a straight regression line has been fitted to the data. This shows that the compound rate of growth in output has been 1% for the past 36 years, whilst the compound rate of increase in productivity has been approximately 0.5% over the same period.

[Fig 1: Long term output and productivity trends]

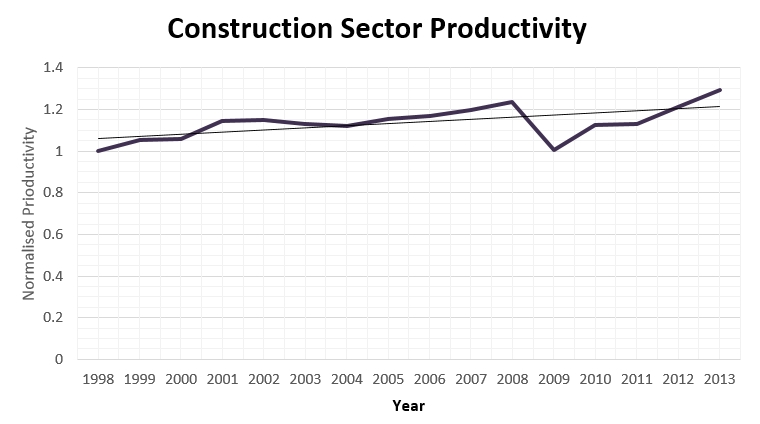

Figure 2 shows changes in productivity measured in terms of Gross Value Added (GVA at constant 2011 prices) per average number employed during the year for the period 1998 to 2013, the only years for which GVA is available.

[Fig 2: Trend in productivity measured in terms of GVA per hour worked]

The compound rate of growth over this 16 year period is about 1% or roughly twice that measured in terms of total output. This suggests either that there has been a growth in capital investment (mechanisation) or technological progress (innovation) or both.

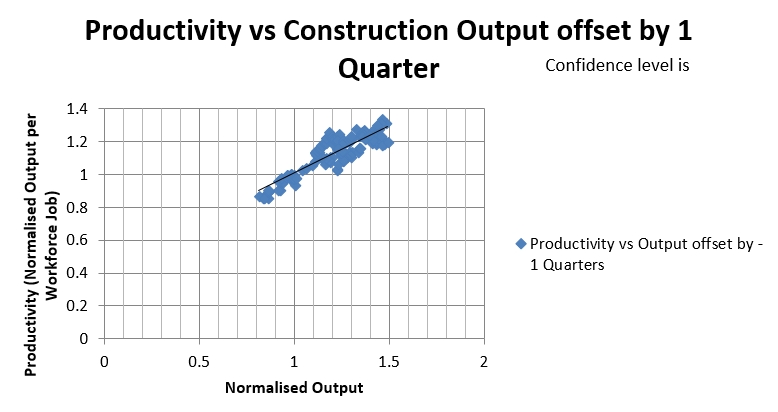

Figure 3 shows the relationship between productivity measured in terms of total output per person employed and output for the period 1978 to 2014. The confidence level in the linear regression is greater than 99%.

[Fig 3: Productivity vs construction output]

This very powerful relationship appears to overshadow other factors and suggests that the dominant factor affecting productivity is the level of activity in the construction industry.

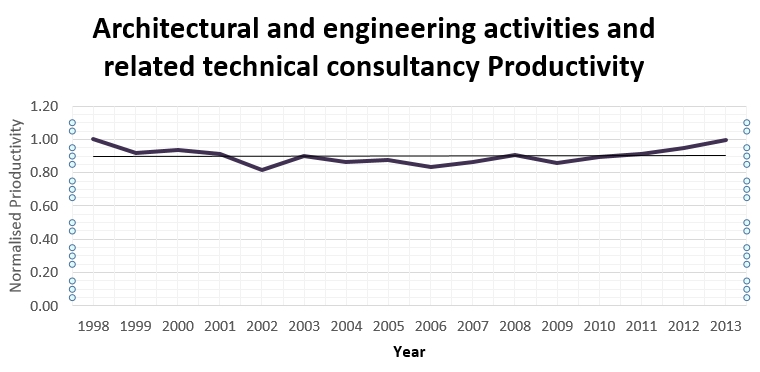

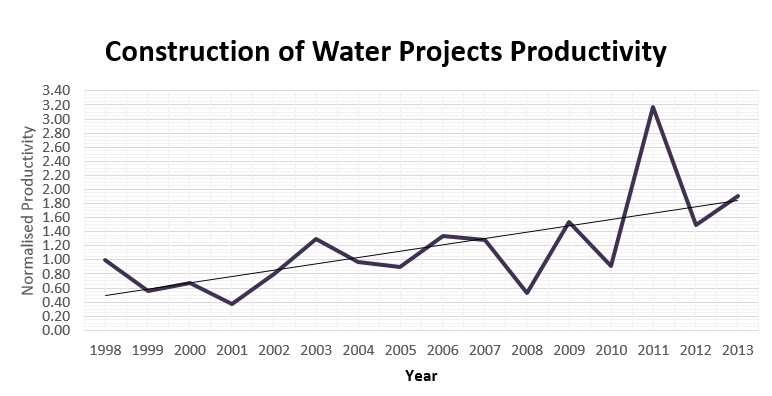

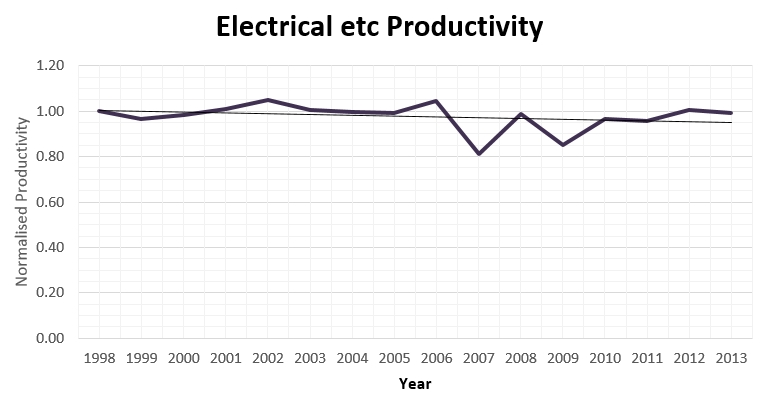

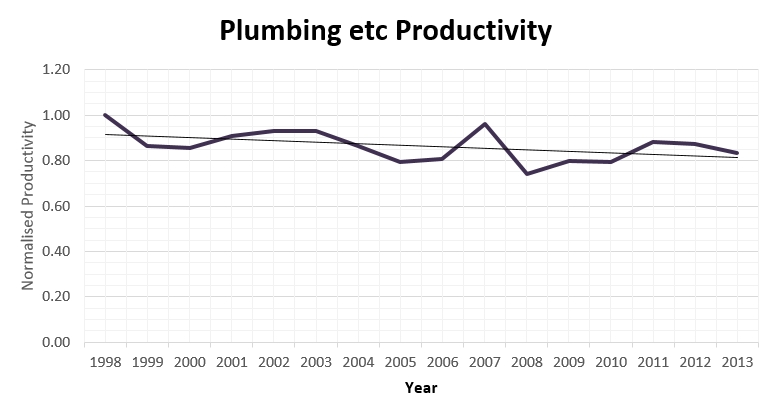

Figures 4, 5, 6, and 7 show changes in productivity measured in terms of GVA per yearly average of number employed for Architectural and Engineering Activities, Construction of Water Projects, Electrical Trades, and Plumbing Trades respectively.

[Fig 4: Productivity Trend in Architectural and Engineering activities]

[Fig 5: Productivity Trend in Construction of Water Projects]

[Fig 6: Productivity Trend in Electrical Trades]

[Fig 7: Productivity Trend in Plumbing Trades]

The lack of significant change in the productivity of the professions is understandable, though it will be interesting to see whether or not the increased use of BIM in future years has an impact. The very significant rise in productivity in the construction of water projects may be a result of the presence of a Regulator, whilst the downward trends in electrical and plumbing trades are more difficult to explain. However, it may be that not all plumbers and electricians are being captured in the statistics, which include only specialist firms and ignore the tradesmen employed by general contractors. It follows that trends reported for individual trades should be viewed with the utmost caution.

[edit] Potential causes of changes in productivity

For convenience, we have divided the potential causes of changes in productivity into external and internal factors. External factors relate to the organisational or industrial environment whilst internal factors are those that are clearly within the control of site management.

[edit] External factors

[edit] Economic Cycle

The expert panel were unanimous in their view that the economic cycle had a major impact on the productivity of the industry and Figure 3 supports that view.

[edit] Competition

Competition might be expected to play a major role in causing changes in productivity, but we could find no evidence to support that view. This may in part be due to the current industrial environment where developers have more interest in end-to-end productivity than performance in any one phase of a development.

[edit] Relationships

In recent years, there has been an increasing recognition of the impact of trusting relationships on productivity. Partnering and alliancing are modern forms of contract designed to share risk in a more equitable manner than traditional ICE and JCT forms of contract. Co-location of client, designer and contractor teams lead to joint ownership and resolution of problems, increased awareness of the impact of delays, and an increased understanding of making the design ready before construction begins. The Expert Panel was clear that client relationships played a major role in improving productivity.

[edit] Creativity

There is considerable evidence to show that innovation is an important driver of productivity improvement. Innovation may embrace both products and processes, but can be constrained by regulations that restrict creative freedom. It is necessary both to incentivise productivity and to exercise a reasonable balance between the need of the supply chain for creative freedom and the need of client organisations for a reasonable degree of control.

[edit] Internal Factors

The most important internal factors affecting productivity are: delays, working hours, size of the labour force, quality and training of the labour force, quality and training of management, and potentially off-site construction, though data relating to off-site construction is hard to find. Of course, some internal factors may also be influenced by external factors.

[edit] Delays

Delays may take one of two forms: interruptions, which bring work to a complete standstill, and disruptions which slow work down without causing an interruption. The major causes of interruptions are shown in Figure 8. Interruptions lasting less than 15 minutes have no impact on productivity, but those lasting more than 15 minutes cause an average loss of productivity approaching 30 % during the time that men remain at work. This is thought to result from the time lost in closing down and starting up an activity when an interruption takes place. Disruptions cause a loss of productivity of about 25%.

[edit] Working hours

If overtime is worked consistently for more than about three months or so, there is, in round terms, a loss of about 1% in productivity for every hour per week worked above 40.

[edit] Increase in the size of the workforce

The size of the labour force has different impacts on productivity depending on whether any increase was planned or unplanned. A doubling in the size of the workforce that is properly planned in advance causes a loss of productivity of about 2½% whilst an unplanned doubling in size causes a loss of productivity of ten times that amount.

[edit] Quality and training of labour force

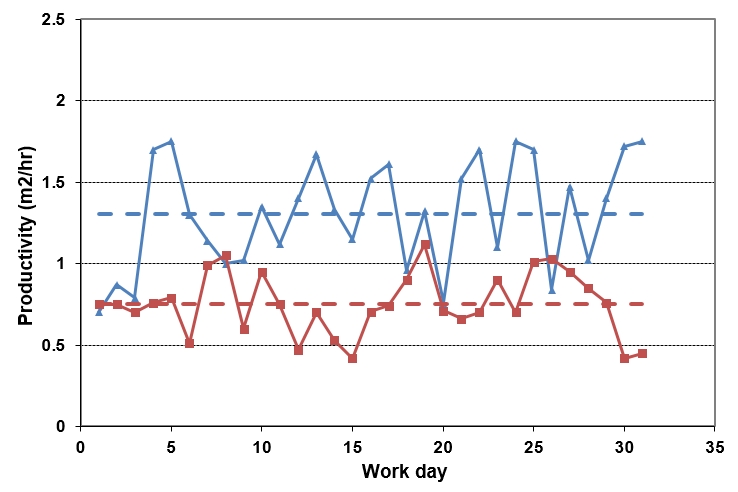

Fig 8 shows that the average productivity of two gangs on the same site doing identical jobs under identical conditions at the same time can differ by as much as 75%.

[Fig 8: Effect of quality and training of labour force]

[edit] Conclusion

Construction productivity in general has increased by about 1% year on year for the past 16 years, but the evidence for individual trades is mixed and unreliable. The strong correlation between productivity and overall output of the industry overshadows other factors. Nevertheless, it can be argued that all of the internal causes of changes in productivity are the result of management actions. Delays can be avoided by good planning. Working hours and the size of the workforce are decided by management.

The quality of the labour force is a function of the way in which it is selected and trained: both are the responsibility of management. The provision of training in the causes of low productivity and the actions that can be taken to improve it for both first line supervisors and senior management throughout the supply chain could therefore yield a handsome dividend for contractors and clients alike.

--BSRIA

[edit] Related articles on Designing Buildings

- Benchmarking.

- BIM.

- BSRIA.

- Can relationships in and between organisations make tangible differences to business performance?

- Collaborative practices.

- Earned value.

- Key Performance Indicators.

- Large Industrial Sites report.

- Leadership styles.

- Modernise or die - the need for change in construction.

- Productivity in building design and construction.

- Productivity in construction: Creating a framework for the industry to thrive.

- Tackling the productivity challenge.

- Team behavioural roles.

- Team building.

- The history of human resource management.

- The state of UK construction August 2012.

- Trade unions

Featured articles and news

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”