What are the important reasons for putty powder de-powdering?

Putty powder is a kind of building decoration material, the main components are talcum powder and glue. The white layer on the surface of the rough house just purchased is putty, usually the whiteness of the putty is above 90 and the fineness is above 330.

Putty is a base material used for wall repair, which lays a good foundation for the next step of decoration (painting and sticking wallpaper). Putty is divided into two kinds: inner wall and outer wall. The outer wall putty has to resist wind and sun, so it has high glue, high strength, and a slightly lower environmental protection index. The comprehensive index of interior wall putty is good, healthy and environmentally friendly, so the interior wall is not used externally, and the exterior wall is not used internally. Usually putty is gypsum or cement-based, so that the rough surface is easier to bond firmly. However, during construction, it is still necessary to apply a layer of interface agent on the base to seal the base and improve the adhesion of the wall, so that the putty can better bond to the base.

Many putty powder users have to admit that de-powdering of putty rubber powder is a very serious problem, which will cause the latex paint to fall off, as well as the bulging and cracking of the putty layer, which in turn causes cracks in the latex paint finish.

Putty powder removal and whitening are the most common problems after putty construction. To understand the reasons for putty powder removal, we must first understand the basic raw material components and curing principles of putty powder, and then combine the wall surface during putty construction. Dryness, water absorption, temperature, dryness of weather, etc.

8 main reasons for putty powder to lose powder, let's take a look!

Reason one

The adhesive strength of the putty is not enough to cause the powder to be removed, and the manufacturer blindly reduces the cost. And the quality of glue and the amount of addition have a lot to do.

Reason two

Unreasonable design formula, material selection and structural problems are very important in putty formula. For example, hydroxypropyl methyl cellulose (HPMC) is used as a putty that is not waterproof for interior walls. Although HPMC is expensive, it does not work with fillers such as shuangfei powder, talc powder, wollastonite powder, etc. If only HPMC is used, it will cause dehydration. However, CMC and CMS cannot be used as waterproof putty, nor can they be used as external wall putty, because CMC and CMS will react with lime calcium powder and white cement, which will cause dehydration. powder, and also adding polyacrylamide to gray calcium powder and white cement as a waterproof coating, which will also cause a chemical reaction to cause powder removal.

Reason three

Uneven mixing is the main reason for de-powdering of internal and external wall putty. Some manufacturers in the country produce putty powder with simple and varied equipment. They are not special mixing equipment.

Reason four

Errors in the production process cause the putty to be de-powdered. If the mixer does not have the function of cleaning and there are many residues, the CMC in the ordinary putty will react with the lime calcium powder in the waterproof putty, and the CMC, CMS in the interior wall putty and the exterior wall will react. The white cement of the putty reacts and causes powder removal. Some companies have special equipment with a cleaning port, which can clean the residues in the machine, not only to ensure the quality of the putty, but also to use one machine for multiple purposes. Buy one equipment to produce a variety of putty.

Reason five

The difference in the quality of fillers is also likely to cause de-powdering. A large number of fillers are used in internal and external wall putty, but the content of Ca2CO3 in heavy calcium powder and talc powder varies from place to place, and different pH levels will also cause de-powdering of putty, such as Chongqing and Chengdu. The same rubber powder is used for the interior wall putty powder, but the talc powder and heavy calcium powder are different. In Chongqing, the powder is not removed, but in Chengdu, the powder is not removed in Henan and Northeast China, and the powder is removed in some areas.

Reason six

The weather is also one of the reasons for the powder removal of the internal and external wall putty. For example, the internal and external wall putty has a dry climate and good ventilation in some arid areas in the north. There is rainy weather, long-term humidity, poor film-forming properties of putty, and powder removal, so some areas are suitable for waterproof putty with ash calcium powder.

Reason seven

Inorganic binders such as ash calcium powder and white cement are impure and contain a large amount of double fly powder. The so-called multi-functional gray calcium powder and multi-functional white cement on the market are not pure. Because of the large use of these impure inorganic binders, the waterproof putty for interior and exterior walls must be de-powdered and not waterproof.

Reason eight

In summer, the water retention of exterior wall putty is not enough, especially in high-rise doorways, windows and other places with high temperature and ventilation, the lime calcium powder and cement will lose their moisture if the initial setting time is not enough, and they will be seriously de-powdered if they are not well maintained.more

Featured articles and news

The Building Safety Forum at the Installershow 2025

With speakers confirmed for 24 June as part of Building Safety Week.

The UK’s largest air pollution campaign.

Future Homes Standard, now includes solar, but what else?

Will the new standard, due to in the Autumn, go far enough in terms of performance ?

BSRIA Briefing: Cleaner Air, Better tomorrow

A look back at issues relating to inside and outside air quality, discussed during the BSRIA briefing in 2023.

Restoring Abbotsford's hothouse

Bringing the writer Walter Scott's garden to life.

Reflections on the spending review with CIAT.

Retired firefighter cycles world to raise Grenfell funds

Leaving on 14 June 2025 Stephen will raise money for youth and schools through the Grenfell Foundation.

Key points for construction at a glance with industry reactions.

Functionality, visibility and sustainability

The simpler approach to specification.

Architects, architecture, buildings, and inspiration in film

The close ties between makers and the movies, with our long list of suggested viewing.

SELECT three-point plan for action issued to MSPs

Call for Scottish regulation, green skills and recognition of electrotechnical industry as part of a manifesto for Scottish Parliamentary elections.

UCEM becomes the University of the Built Environment

Major milestone in its 106-year history, follows recent merger with London School of Architecture (LSE).

Professional practical experience for Architects in training

The long process to transform the nature of education and professional practical experience in the Architecture profession following recent reports.

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

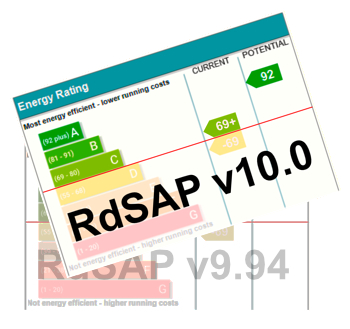

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.