Weep hole

Contents |

[edit] Introduction

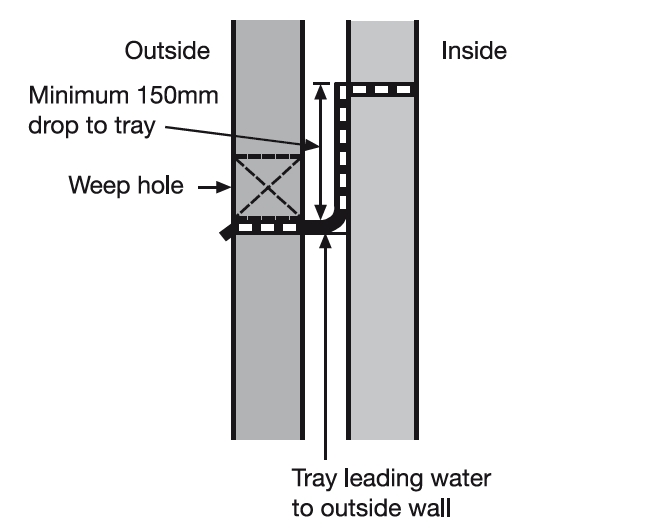

Brick and stone are porous materials and can absorb and store water. The inclusion of weep holes in masonry walls is intended to serve two purposes:

- Drainage: They provide an opening that allows the drainage of any moisture that may reach the back of a wall, or the inside leaf of a wall (such as a cavity in cavity wall construction) from the outside through penetration, capillary action, condensation, leakage or flooding.

- Ventilation: They allow ventilating air to the back of a wall to help prevent mildew, dry rot and damp which might otherwise reduce the life or performance of building materials such as cavity wall-ties, cavity insulation and so on.

The Masonry Design Manual describes weep holes as, ‘Openings placed in mortar joints of facing materials at the level of flashing, to permit the escape of moisture, or openings in retaining walls to permit water to escape.’

Weep holes are typically found in the outer masonry leaf of cavity walls, just above the flashing. They can also be found above windows, doors or other penetrations. They should be provided at regular intervals so as to allow any moisture collected by cavity trays to escape. The recommended distance between weep holes is 450mm.

[edit] Types of weep holes

[edit] Open head joints

These are formed by omitting mortar from the vertical joint between bricks. Holes are created that are the same size as the typical joint spacing. The spacing between open head joints is typically done at 24 inch (61cm) intervals. They may include plastic weep vents which incorporate a baffle structure to prevent rain from penetrating through the hole and preventing insects from entering the cavity. They may also include a drip at the front lip to aid drainage.

[edit] Cotton rope wicking

A rope of up to 12 inches (30cm) in length is placed in the joints and the other end is extended up into the cavity wall. The moisture inside the wall is absorbed by the cotton and wicked to the outside where is evaporates. This process is slower than with ordinary weep holes.

[edit] Tubes

Tubes made of hollow plastic or metal can be used as weep holes, spaced around 16 inches (41cm) apart. They are placed at a slight angle to allow water egress. Care must be taken to ensure the angle is not too steep or too flat.

Alternatively, oiled rods or ropes can be placed and mortared into the joints. The oil prevents mortar bond and the rods or ropes are removed after setting which leaves a hole similar to that of a tube. The advantage of these techniques is that they are less conspicuous.

[edit] Problems with Weep Holes

[edit] Pest entry

Weep holes can provide access to the wall cavity for unwanted pests such as rodents and insects. Penetrations such as down lights, extractor fans and holes for plumbing or electronics then serve as an internal entry point. Baffled vents can help prevent this problem.

[edit] Trash mortar

As mortar is squeezed out from between successive courses of brick, droppings can fall behind the wall and build up. This can result in weep holes becoming partially, or totally, blocked by trash mortar. Mortar collection devices can be installed to try and alleviate this problem.

[edit] Obstruction of air flow

Measures to try and combat the problems above, as well as make weep holes more aesthetically pleasing, can result in them not providing the necessary flow of air to properly ventilate the internal brick wall.

[edit] Related articles on Designing Buildings Wiki

- Airbrick.

- Building damp-free cavity walls.

- Cavity wall insulation.

- Cavity tray.

- Damp proof course.

- Flashing.

- Lintel.

- Masonry.

- Perpend.

- Rainscreen.

- Wall tie failure.

- Wall types.

[edit] External references

- BPGWI – EA Weep holes

- Masonry Construction – Installing weep holes

Featured articles and news

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”