Types of insulation

Contents |

[edit] Introduction

Thermal insulation materials have a low thermal conductivity which serves to limit the flow of heat energy between one side of the insulation and the other. In the build environment thermal insulation is typically used to reduce the passage of heat between the inside of a building and the outside.

For more information see: Thermal insulation.

There are many different types of insulation, which vary in terms of colour, surface finish texture, core composition and performance. Very broadly however, they tend to be open cell or closed cell.

|

|

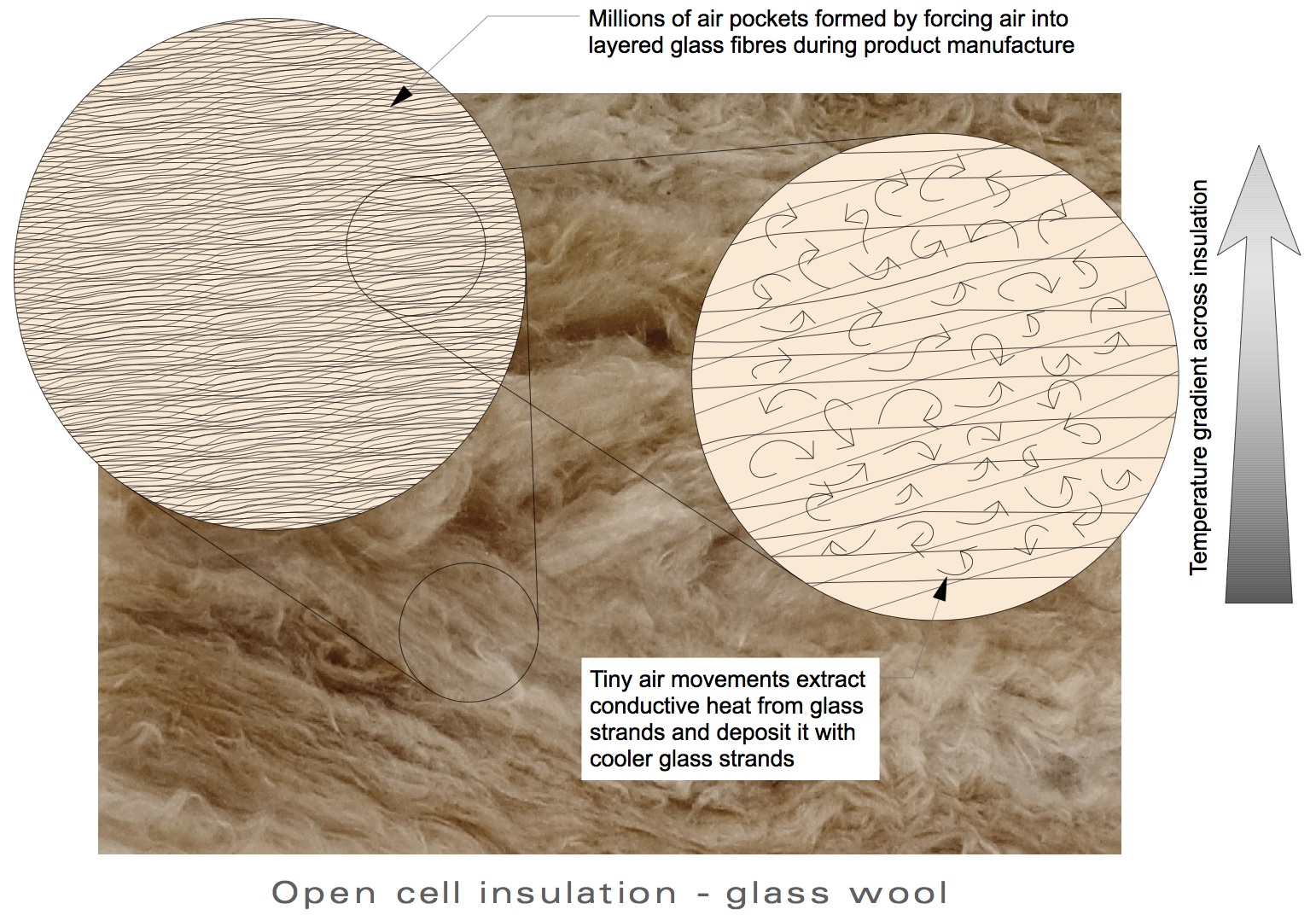

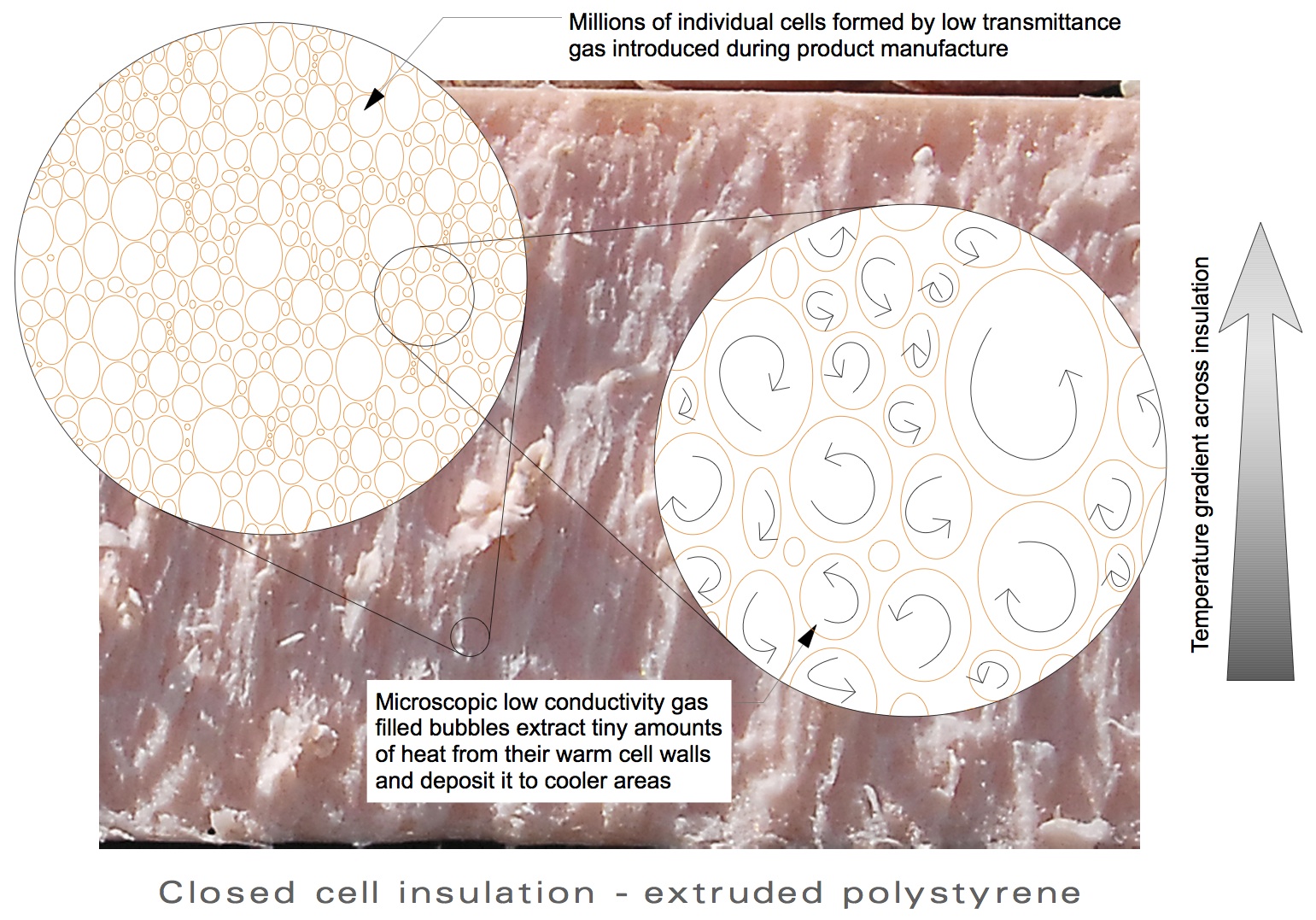

| Open cell insulation | Closed cell insulation |

Open cell insulation allows the passage of air through air pockets, but the route is so complex that effectively, no air will pass from one side to the other, and so heat transfer by convection is prevented. Closed cell insulation is formed by bubbles of gas whose thermal conductivity is very low.

Some of the more common types are described below.

[edit] Blanket insulation (also called matting insulation)

This is generally the easiest to install and is commonly used as roof insulation. It typically comes in foil-backed rolls which can be placed between joists or rafters, and may be held in place by timber battens attached to and across the joists or rafters.

It is usually made of mineral or glass wool but can also be made from plastic fibres, and natural fibres such as cotton and sheep’s wool. The depth of blanket-style insulation varies depending on the exact composition and the performance required, but it is typically in the range of 100-200 mm.

[edit] Mineral wool

Mineral wool generally refers to fibre materials that are formed by spinning or drawing molten minerals. It can be manufactured in various thicknesses and widths and is often supplied in rolls.

[edit] Sheep’s wool

This type of insulation has the benefit of being 'sustainable', and offers an effective alternative to other synthetic types of insulation. It is increasingly being used between roof beams, under floors and in solid walls. It is often treated to make it more fire and insect resistant.

[edit] Glass wool

This type of insulating material consists of glass fibres arranged using a binder into a wool-like texture. Glass wool can be produced in a variety of ways, such as in rolls, slabs, applied in place, or sprayed.

[edit] Foam boards

These are rigid panels of insulation which are cut and fitted in place. Most commonly they are made from polystyrene, polyisocyanurate, and polyurethane, and may be fitted to a depth of around 175 mm. They are used predominantly where there is weight that needs support, i.e. under a floor or in a loft. The benefits of foam boards are that they are durable and can also provide acoustic insulation.

[edit] Radiant barriers

These inhibit heat transfer by thermal radiation. They are capable of being stapled to the underside of rafters. They are more effective in hot climates, where reduced heat gain may allow for smaller air conditioning systems. In cool climates, installing more thermal insulation it is usually more cost effective. The thickness of a radiant barrier is usually between 3-5 mm.

[edit] Blown-in insulation

This involves mineral fibres being blown into a void in the space that needs insulating. Although requiring specialist equipment, it is quick to install and can be effective for spaces with limited access, such as gaps between roof joists or cavity walls. The most common materials that are used include cellulose, fibre glass and mineral rock wool.

[edit] Spray foam insulation

Typically, spray foam is formed of polyurethane and is sprayed as a liquid which gradually expands to up to 100 times its original volume. Once set, it creates an effective thermal and noise insulating layer. Slow-curing foams can be used for cavity walls as they will flow around any obstructions before hardening. As spray foam can produce dangerous fumes and damage the structural integrity of the building if applied incorrectly, professional installation is recommended.

[edit] Structural insulated panels (SIPs)

Structural insulated panels (SIPs) are a form of composite sandwich panel system that incorporates insulation, predominantly used for residential and light commercial construction. They take the form of an insulating core (such as closed-cell polyurethane foam or expanded polystyrene) sandwiched between two structural facings.

The benefits of using SIPs are that they are high-strength, provide good thermal performance and can be fabricated to fit nearly any building design.

For more information, see Structural insulated panels.

[edit] Aerogel insulation

Aerogels are synthetic low-density materials with unique physical properties. Due to their high porosity, aerogels exhibit the lowest thermal conductivity of any solid, whilst being transparent to light and solar radiation. Aerogels are often cited as a promising material for translucent insulation applications.

Commercial products for the building sector include:

- Cavity insulation.

- Glazing units and cladding systems containing granular aerogel.

- Translucent and opaque insulation boards, blankets and tensile roof membranes embedded with aerogel particles.

For more information, see Aerogel.

[edit] Other types of insulation

Insulation also has other uses in the construction industry:

- Acoustic insulation to prevent the transmission of sound. For more information see: Acoustic insulation.

- Fire insulation to prevent the passage of fire between spaces or components.

- Electrical insulation to contain and separate electrical conductors.

[edit] Related articles on Designing Buildings

- Aerogel insulation for buildings.

- BREEAM Insulation.

- Cavity wall insulation.

- Fire insulation.

- Floor insulation.

- Glass bottle floor foundation.

- Heat transfer.

- Icynene spray foam insulation

- Insulation.

- Insulating concrete form.

- Insulation for ground floors.

- Sarking.

- Sheathing.

- Solid wall insulation.

- Sound insulation.

- Structural insulated panels.

- Thermal insulation for buildings.

- Transparent insulation.

Featured articles and news

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Comments