The Role of Different Sizes of Aggregates in the Construction Industry

Contents |

[edit] Why Aggregate Size Matters in Construction

In the construction and mining industries, aggregates serve as the backbone of all infrastructure projects. Whether used in concrete, road base, or drainage systems, aggregates of different sizes play crucial roles in determining the strength, durability, and performance of construction materials. From fine sand to coarse crushed stones, each size category contributes uniquely to the final product. Understanding these roles is essential not only for engineers and contractors but also for quarry operators running an aggregate crusher plant or a mobile stone crusher plant.

The size and gradation of aggregates affect everything from concrete workability to the compaction of road sub-layers. Coarse aggregates offer strength and load-bearing capabilities, while finer particles fill the gaps and enhance bonding. This balance of particle sizes ensures that structures are solid, long-lasting, and able to withstand environmental stresses.

A well-graded aggregate mix improves workability, minimises voids, and reduces the need for excess cement or bitumen. Whether sourced from a fixed aggregate crusher plant or processed on-site using a mobile stone crusher plant, choosing the right size of aggregates for each application is a fundamental aspect of quality construction.

[edit] Types of Aggregates by Size

[edit] Fine Aggregates

Fine aggregates usually consist of natural sand or crushed stone particles smaller than 4.75 mm. They fill the voids between coarse aggregates and act as a bonding agent when mixed with cement or asphalt.

Applications:

- Plastering

- Bricklaying mortar

- Concrete finishing layers

[edit] Coarse Aggregates

These are particles greater than 4.75 mm and usually range from 10 mm to 40 mm in diameter. Coarse aggregates are primarily used for structural strength and to reduce shrinkage in concrete.

Applications:

- Foundations and footings

- Road bases

- Structural concrete

[edit] All-in Aggregates

All-in aggregates are a mix of both fine and coarse materials. They are commonly used when a pre-mixed blend is required for non-critical construction tasks.

Applications:

- Driveways

- Filling materials

- General backfilling

[edit] How Aggregate Size Affects Concrete and Asphalt

[edit] Strength and Load-Bearing Capacity

Larger aggregate particles generally offer higher strength due to reduced surface area and lower water demand. They create a solid internal structure, especially useful in load-bearing components such as bridge decks or industrial floors.

[edit] Workability and Pump ability

Smaller aggregates improve the workability of concrete, making it easier to pour and shape. However, too much fine material can lead to segregation or bleeding. Finding the right balance between fine and coarse materials ensures that the mix flows properly without compromising structural strength.

[edit] Surface Finish

Fine aggregates are crucial in finishing applications. They contribute to a smoother surface texture in concrete floors, walls, and architectural elements. Coarser materials are not suitable for finishes but are essential for internal bulk.

[edit] The Role of Crushing Plants in Aggregate Production

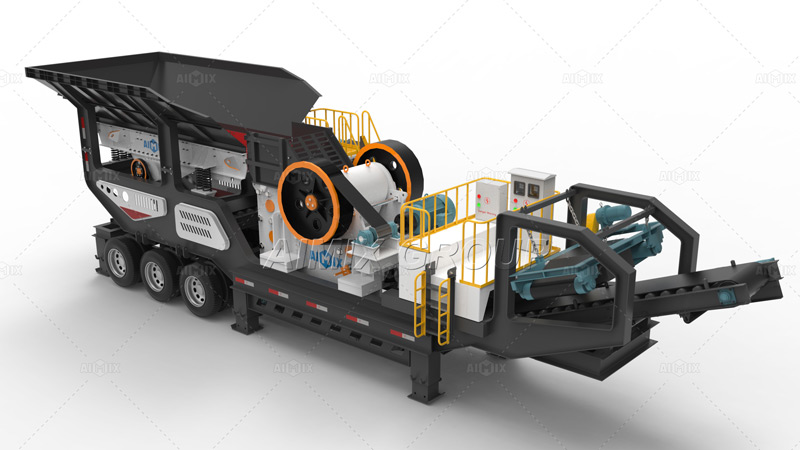

To meet specific construction requirements, raw stones are processed into different aggregate sizes using crushing and screening equipment. A fixed aggregate crusher plant is ideal for large-scale operations where consistent production is needed. These plants feature multiple crushing stages and sieving systems to produce well-graded materials suitable for various applications.

On the other hand, a mobile stone crusher provides flexibility for on-site crushing, especially in remote or temporary construction zones. These portable units reduce transportation costs and allow operators to process materials directly at the job site, ensuring faster project completion and reduced environmental impact.

[edit] Gradation and Blending for Optimal Performance

Construction materials often require specific gradation curves to meet project standards. This involves blending various sizes of aggregates in the right proportions. For instance, concrete pavements may require a different gradation than structural columns or drainage layers.

Modern crushing plants can be configured to produce multiple aggregate sizes simultaneously. This not only increases operational efficiency but also ensures quality control throughout the production process.

[edit] Conclusion

Different sizes of aggregates serve distinct functions in the construction industry, from structural strength to aesthetic finishing. Choosing the right size, or combination of sizes, can dramatically affect a project’s durability, cost, and performance. With the help of advanced crushing technologies—whether from a centralised aggregate crusher plant or a versatile mobile stone crusher plant—contractors and engineers have greater control over material specifications and supply chain logistics.

Understanding how aggregate size influences construction outcomes is key to building stronger, more efficient, and sustainable infrastructure in today’s demanding world.

[edit] Related articles on Designing Buildings

- Aggregate.

- Aggregates levy.

- Ballast.

- BREEAM Recycled aggregates.

- Bulk filling materials.

- Chert.

- Coal ash.

- Concrete masonry unit CMU.

- Construction aggregates market 2016 - 2024.

- Global construction aggregates market revenue to 2021.

- Gravel.

- Gravel v hardcore v aggregates.

- Hardcore.

- Manufacture of lightweight aggregate granules containing phase change materials.

- Material Flow Analysis: A tool for sustainable aggregate sourcing.

- Recycled aggregates.

- Sustainable aggregates.

Featured articles and news

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.