Supply chain collaboration

For projects to succeed, we need to communicate the real benefits of collaboration throughout the entire supply chain and commit to supporting them in the adoption of new behaviours.

[edit] Introduction

A JCP survey, in which we spoke to over 100 people within the infrastructure industry, revealed that most people are clear about the benefits of working collaboratively. In today’s financially and time-constrained environment, our respondents understand that traditional contracting models are less likely to work and a new method of project success needs to be employed.

Those same respondents, all clients and senior managers from a range of utility and other industrial sectors, also reflected that collaborative working is hard work. It takes everyone involved to be fully committed and it requires on-going attention and support in order to sustain it – although the benefits, for those who fully embrace this way of working, are plentiful.

And yet something has to be done. A 2015 report by the Economist on ‘Rethinking productivity across the construction industry: The challenge of change’ reflects that increasing productivity continues to be an industry-wide problem which makes it difficult for individual organisations to find solutions on their own. “Improving productivity at the industry level will require changes in the expectations and behaviours of all stakeholders, including clients, policymakers, and supply-chain partners as well as the contracting community itself.”

This traditional approach leads to hierarchical thinking which tends to leave the supply chain in a precarious position. JCP’s approach focuses on the customer and what’s adding value. The Government’s Alliancing Code of Practice suggests giving the contractor ‘licence to challenge’.

While collaborative working is a solution to making the necessary productivity improvements, one of the biggest findings of the survey relates to generating that sense of commitment from everyone involved. While ensuring genuine buy-in from the client can be a challenge, persuading the supply chain of the benefits can be equally as daunting.

Over 80% of our survey respondents told us they felt members of the supply chain and frontline were sceptical about the advantages of working collaboratively.

The reality, however, is that the real benefits of collaboration are unlocked within the supply chain. As one respondent clearly stated: “... whenever we bring the supply chain closer to the client organisation, that’s where the magic happens in terms of joint incentives.”

[edit] How to engage the supply chain?

So how can we engage this important group? What are the hooks that might persuade them to get involved? And in particular, what are the arguments for the supply chain beyond tier one?

In JCP’s 20 years of experience, and also that of our clients, we have all, at one time or another, come across the difficulty of engaging and inspiring this group to work collaboratively. As The Economist report puts it, “…improving productivity demands a prescription of collaboration that supports a culture of shared risks and rewards across the value chain and a willingness to think and act beyond the context of individual projects. Breaking down the siloes that exist between stakeholder groups and building long-term relationships that allow identification of opportunities for improvement is the first step.”

The following points, some more obvious than others, have all proven to be the compelling enticement that sceptical or worried organisations have needed to get on board:

[edit] Improved delivery to the client

Mentioned by a number of respondents, this is a key benefit of collaboration. The advantage of completing a project on time, on spec and under budget is clearly a huge motivator for everyone involved and leads to reputational success. That’s obvious but while many tried and tested project management methods may be called upon, building a true alliance or integrating other collaborative techniques proves, over and over again, to be the most likely system of practice to generate the best results.

This also leads squarely to:

[edit] Repeat business

Better, more collaborative relationships, which are more fulfilling and successful to work within, lead to people and organisations wanting to work together again in the future. In today’s world where even business transactions are described as ‘people relationships’ or B2P rather than B2B, this is increasingly important.

Where supporting collaborative tools such as BS11000 Collaborative business relationships, or the Government’s Alliancing Code of Practice are becoming more prevalent, endorsing this approach will ensure suppliers/contractors are on the procurement list for those organisations – and even industries – who want to work this way. In fact, this goes further.

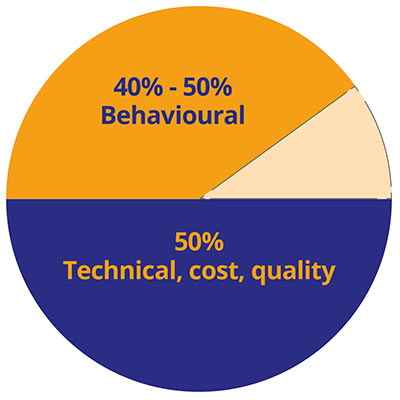

The behavioural aspect of tenders can make up to as much as 50% of the bid score. In a world where technical, cost and quality variations don’t differ that much, this is a sizeable chunk that could easily see a supplier/contractor first over the finishing line.

[edit] Avoids the energy sapping nature of conflict

Not just a better place to work, aligned goals and behaviours and a better understanding of the needs of others actually means less time wasted.

[edit] Clarity of direction Better use of time. Avoidance of re-work.

These interlinked benefits should speak to members of the supply chain, particularly beyond tier one, more than any other. Those companies who are often struggling for resource should welcome the opportunity to work within a higher-performing team where there are clear goals, and action plans and deviations are grasped quickly and dealt with properly.

[edit] Financial issues resolved quickly

Better relationships usually lead to being paid on time, which has got to be a major benefit.

[edit] Happier workforce

People who are working in a more pleasant work environment due to better collaboration are happier and more likely to deliver in line with both their and others’ needs. In fact, a survey carried out by Google into collaboration and innovation in the workplace, found that: “…respondents who strongly agreed that their company fostered a culture of knowledge-sharing and collaboration, also strongly agreed that employee morale and job satisfaction were high. Whilst a direct correlation hasn’t been proved, it suggests that a culture of collaboration could potentially help alleviate those threats by creating a more desirable work environment”’.

[edit] What can a client do to help their suppliers?

Often, the organisation may be willing but unable to commit to the desired approach. As one of our survey respondents from the rail industry described it, we are, “dealing with a supply chain that is not ready for it”.

[edit] A big factor in securing the input and buy-in of the supply chain has to be helping them get more ready.

It takes time but once their interest is secured, attention turns to the realities. Don’t let these become a contradiction when securing your next alliance:

[edit] Extend the procurement method beyond the Tier One Contractor.

Currently many clients, particularly in the public sector, are procuring partners collaboratively and behaviourally. But this approach is rarely extended through the supply chain where a focus on cost reigns.

One utility company has begun to do some work in this area – trying to get collaborative messages across to the supply chain beyond tier one by procuring them in a similar way to the procurement of key partners for Asset Management Programme 6 (AMP6), with a focus on the right behaviours and attitudes. Work with your procurement teams early in the tendering process to ensure you have a consistent approach across the board.

[edit] Demonstrate that the traditional approach is not necessarily the best way to approach procurement

Work with your procurement teams and show them the value – in terms of time, money and people development, that can be secured by procuring in a more collaborative way. Future leaders may reside in the supply chain – allow their values and attributes to emerge. HM Treasury’s Infrastructure UK Procurement Route Map is a valuable reference.

[edit] Lead by example

It’s not enough to tell organisations they must collaborate more effectively if leadership (within our own organisations and within the supply chain) does not demonstrate and embrace it in the way which we would expect them to. Deloitte also recently conducted a similar collaboration survey of oil and gas operators and oilfield services companies.

Their report stated that “…whilst there was clear recognition of the value of collaboration and what’s needed to make it happen, less than 10% said that leadership regularly emphasised its importance or included it in their business strategy. Despite this 20% of respondents still said they actively sought out opportunities to collaborate, which shows that the potential is there if the right leadership and incentives are in place.”

[edit] Make sure commercial arrangements are inherently collaborative. Commercial models drive behaviours

Don’t stop at the procurement stage; ensure the commercial arrangements also help drive behaviours you are looking for and build trust and commitment from your supply chain members. How can we expect the supply chain to behave collaboratively or even understand what collaborative behaviours are expected when commercial arrangements give a contrary message? Think about changing these arrangements first.

[edit] Collaboration “just means being nice and doing as we are told”

If only it were that simple! The realities behind the hard work – and subsequent benefits – of collaboration need to be properly expressed to all levels of the supply chain. This means leading by example through the structural and commercial arrangements required as well as properly highlighting the behaviours that are expected to collaborate effectively. In fact, expressing these requirements may well be better received than expected since many of the behaviours – challenge, personal responsibility and accountability etc. – dovetail neatly with the behaviours required in health and safety. It is possible to make these links as clearly as we do for Health and Safety.

Deciding to take a collaborative approach is a big commitment. And it’s certainly not the easiest route. So encouraging and supporting the supply chain to get and stay involved will take time and focus from the leading organisation.

Alongside some persuasive arguments to engage suppliers of the benefits, let’s ensure we take responsibility for their involvement. Ask yourself; do we listen to them adequately?, are we addressing their fears?, are our collaborative drivers made clear enough to people at other levels of our organisations?

[edit] Conclusions

A recent survey by the Infrastructure Client Group among industry insiders revealed that almost 50% feel the construction industry is not ready to embrace alliancing and collaborative working on a wider scale. This is an alarming statistic and one we should seek to reverse.

Action on both sides is undoubtedly needed. We may well need the leaders in the supply chain to make the first move but let’s also recognise we may need to engage the supply chain better – after all it’s not all the fault of the supply chain.

This article originally appeared as Why is collaboration so important in the supply chain? published by the Institution of Civil Engineers on 3 March 2016. It was written by Simon Vaughan, Director at JCP Consultancy.

--The Institution of Civil Engineers

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

- BS11000 Collaborative business relationships.

- Can relationships in and between organisations make tangible differences to business performance?

- Collaborative practices.

- Egan Report.

- Framework agreement.

- Government Construction Strategy.

- Integrated project team.

- Integrated supply team.

- Latham Report.

- Leadership styles.

- Partnering.

- Supply chain management.

- Team behavioural roles.

- Team management.

Featured articles and news

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.