Pressing pause to avoid errors

Contents |

[edit] Introduction

Tom Barton of the Get It Right Initiative discusses how the message that eliminating error significantly reduces costs will be fundamental to the survival of many organisations once we return to normal working practices.

[edit] Addressing error rates

One of the central messages of the Get It Right Initiative’s (GIRI) ongoing campaign to eliminate error in the construction industry is the importance of ‘pressing pause to eliminate error’. Sometimes it is better just to stop and take a moment to check that what we are doing is right.

But what happens when we are forced to stop suddenly, and under conditions in which we might not have access to the people, the information or even the technology that we need, to check what we are doing is right? Unfortunately, when we don’t have all of the necessary data, and we don’t revise the plan properly, we risk making things worse.

Covid-19 presents a huge challenge not only to the country as a whole, but also to our industry. There is absolutely no question that when we resume ‘normal’ working, there will be even more pressure on costs and resources, and GIRI’s message that eliminating error reduces costs significantly will be fundamental to the survival of many organisations. Whilst we are facing monumental uncertainty at the present time, the one thing that we can be sure about is that there will be a huge squeeze on costs and a drive to much greater efficiency.

[edit] The price of errors

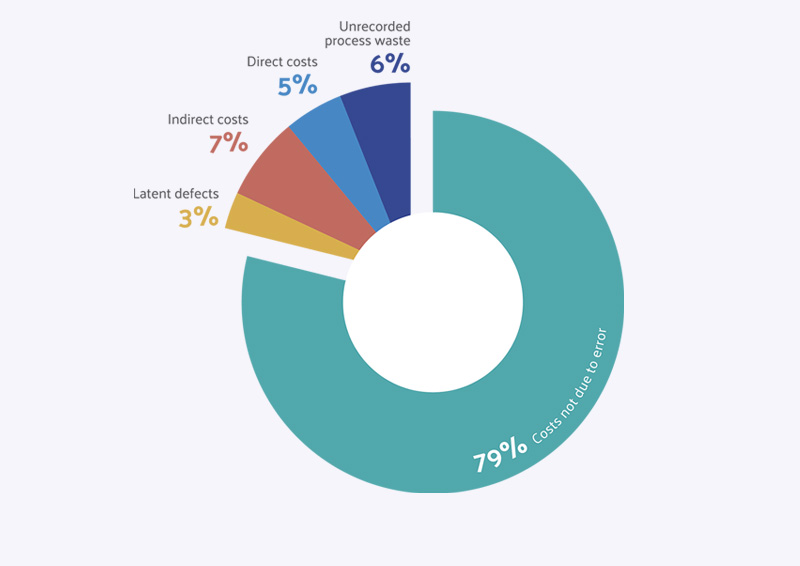

Whilst key studies suggest the direct cost of avoidable error is around 5% of project value, our research among our industry members and their supply chains, both in the UK and internationally, revealed that the true figure is a great deal higher.

When unrecorded process waste, latent defects and indirect costs are included, the situation gets much worse. Estimates of the total cost of errors range between 10% and 25% of project cost or between £10–25 billion per annum across the sector.

When many sites have been closed for an extended period, the consequent disruption and lack of continuity is likely to create conditions in which error frequency will increase. We anticipate that the restart has the potential to cause a spike in error - exacerbating the 10 root causes of error that we identified in GIRI’s Strategy For Change report, as well as creating new causes.

GIRI members have said the main challenges they predict for the restart are:

- How they will manage and motivate staff.

- The underpricing of future works, or the ‘race to the bottom’.

- Sustainability of supply chains.

- Reduced productivity.

- The legal implications of delays.

- The potential loss of competence.

Some of the issues that the industry anticipates once work starts again in earnest are:

- Availability of materials and the potential for inappropriate or lower quality substitutions.

- Adapting to new ways of working

- Unknown errors that might have arisen due to the loss of face-to-face communications.

- Incomplete work that might take time to be identified are just.

[edit] Actions to take

So what can we do to address these issues, and is technology the answer?

While technology has a part to play, there are many other steps that we can take that will contribute to and support the drive to eliminate error.

Our research shows that many of the root causes relate to design; this is not because we have poor designers but because our culture does not enable designers and constructors to work together in a way which eliminates error.

GIRI’s Guide to improving value by reducing design error sets out 12 ways the industry can work to reduce error during the design process. These recommendations resonate almost perfectly with those who urged the industry to use this time to engage engineers ahead of the curve and allow schemes to be delivered more efficiently and effectively.

Now is the perfect time to take stock of what we are doing, reflect on how we are doing things and learn what we can do to improve them. The industry must seize the moment and press pause; we need to change. We cannot afford not to improve the way we do things.

This article was originally published on 21 May 2020 under the title, Pressing pause to avoid error has never been more important. It was written by Tom Barton, Executive Director, Get It Right Initiative and appeared on the Civil Engineering portion of the ICE website.

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

- Articles by ICE on Designing Buildings Wiki.

- A guide to improving value by reducing design error

- Adversarial behaviour in the UK construction industry.

- Conflict avoidance.

- Construction disputes.

- Contract claims.

- Defects.

- Delays on construction projects.

- Disruption claims in construction.

- International research into the causes of delays on construction projects.

- Resilience.

- The Get It Right Initiative

Featured articles and news

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”