How much carbon are your buildings responsible for?

Contents |

[edit] Introduction

Carbon emissions must be reduced drastically if we are to limit global warming to safe levels. Construction is responsible for around 40% of global emissions.

[edit] Reducing embodied and whole-life carbon in buildings

Architectural Technologists are in a position to act positively on this issue by considering the whole life carbon footprint of the designs they develop and how the materials they specify perform in carbon terms.

[edit] Terminology

- Carbon (tCO2e): A simplified term used for describing greenhouse gas (GHG) emissions, measured in tonnes of carbon dioxide (CO²) equivalent. CO² is used as the metric as it is the most prevalent GHG, though it is worth noting that some other GHGs are more damaging to the climate, e.g. methane (CH4) which is at least 20 times as damaging as CO².

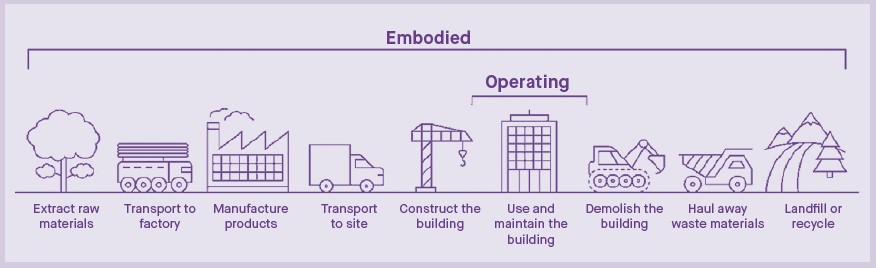

- Embodied carbon: The carbon expended in the production of a building, product or material. For a brick this would include the carbon emissions caused from quarrying raw material, transporting this to where it is processed and manufacturing into a useful product; all occurring before it arrives on your site ready for construction.

- Operational carbon: The carbon expended during operation, i.e. emissions caused by electricity and gas usage, plus refurbishment and/or replacement of materials over the life of a building.

- Whole life carbon: embodied carbon + operational carbon, measured over the buildings’ lifespan. This term takes into account all carbon expended over the life of a building from sourcing raw materials, their impacts in use to how those materials are likely to be treated at the end of their lifespan.

- Life cycle analysis (LCA): This is the process by which a carbon footprint is measured. LCAs to be used in BREEAM assessments usually assume a building lifespan of 60 years.

- Whole building life cycle analysis: The term used to specify that a life cycle assessment is covering a complete building design.

- Life cycle costing (LCC): This is the process for assessing how different design options will perform in cost terms over the buildings’ lifespan, considering their upfront, maintenance and replacement costs.

- Environmental product declaration (EPD certificate): Certification providing proof of the embodied carbon impacts of producing a material or component.

|

| Figure 1: Stages considered in a life cycle carbon assessment. |

[edit] Guidance and legislation

A lot of changes have evolved in this area, including requirements around embodied carbon appearing in the New London Plan and many cities, regions and businesses adopting net-zero carbon targets. Here are some of the key updates.

Firstly, the RICS professional statement on whole life carbon calculation was released in 2017, standardising how carbon footprinting is carried out in the industry. This was much needed to allow safe and reliable comparisons to be made between buildings and for benchmarks to be developed and agreed upon across industry. Before this point, there was no agreed scope for life cycle assessments, leading to disparate and incomparable results.

Secondly, the 2018 version of BREEAM New Construction revised extensively how credits under the ‘Materials’ category are scored. For buildings aiming for high levels of attainment under BREEAM, carrying out LCA is now strongly encouraged.

References to the green guide to specification were removed and the scoring process heavily weighted towards carrying out life cycle analysis of design options, beginning at conceptual design stage. This has encouraged consideration of carbon impacts early in the design process when there is the best chance of making the design both carbon- and material-efficient.

[edit] Software tools

There are a range of tools available to aid in calculation and analysis of the whole life carbon impacts of buildings, including EC3, eTool, OneClick LCA and HBERT. OneClick and eTool are two commercially available tools approved by the BRE for use as part of BREEAM assessments (ref. BREEAM Mat01 tool v1.9).

A process for measuring and reducing whole building life cycle carbon footprints:

- Baseline calculation.

- Carbon hotspot analysis.

- Identify carbon reduction opportunities.

- Establish project reduction target.

- Refine opportunities.

- Incorporate opportunities into the design.

[edit] Carbon hotspots

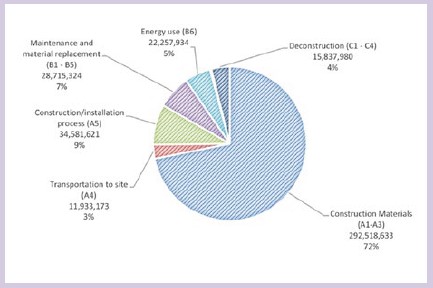

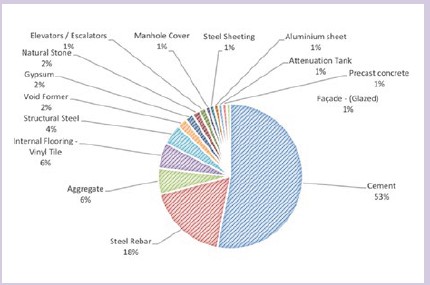

Carbon hotspots are where the highest proportion of a buildings’ carbon footprint are found. These could be defined either by life cycle stage, building element or by material. The results of a recent carbon baselining exercise are presented in the following pie charts.

| Figure 2: Carbon baseline figures by life cycle module. |

|

| Figure 3: Carbon baseline materials hotspots. |

|

In this example, modules A1–A3 (Figure 2) were found to be the biggest life cycle stage carbon hotspot, and cement (Figure 3) was the biggest materials carbon hotspot. With this information, the design team could focus their carbon reduction efforts on their materials specification, developing low carbon opportunities and specifications, particularly for concrete elements.

[edit] Taking action

In summary, it is easier than ever to determine and act on the carbon footprint of designs. This is possibly the biggest opportunity for Architectural Technologists to make a positive contribution towards global decarbonisation efforts.

[edit] Rules of thumb

- Prioritise creative re-use, refurb and retrofit over new build. Retaining or reusing built elements avoids all carbon associated with demolition, transport and processing.

- Maximise structural efficiency. Adopting a lean design approach can drastically reduce materials quantities. We saved 1000 tonnes of steel from a railway station roof through additional analysis and design.

- Limit use of carbon-intensive materials. Use carbon-intensive materials where they are needed and of most use, but avoid them in any other situation.

- Use materials with high-recycled content. Recycled material is generally lower in carbon than virgin.

- Specify low-carbon concrete mixes. Use cement replacements wherever possible. We are specifying up to 70% cement replacement on several projects.

- Choose carbon sequestering materials. Use timber and other biological materials when possible.

This article originally appeared in the Architectural Technology Journal (at) issue 133 published by CIAT in Spring 2020. It was written by James Robb BSc (Hons) MCIAT

--CIAT

[edit] Related articles on Designing Buildings Wiki

- Architectural technologist.

- BREEAM UK New Construction 2018 changes summary.

- Carbon footprint.

- CIAT articles.

- Greenhouse gases.

- Life cycle in the built environment.

- Low carbon.

- Royal Institution of Chartered Surveyors RICS.

- Whole-life costs for buildings WLC.

- Wood, embodied carbon and operational carbon.

Featured articles and news

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.