Sustainable procurement

Sustainability is a broad term describing a desire to carry out activities without depleting resources or having harmful impacts, defined by the Brundtland Commission as 'meeting the needs of the present without compromising the ability of future generations to meet their own needs.' Some broader descriptions also include consideration of social and economic welfare.

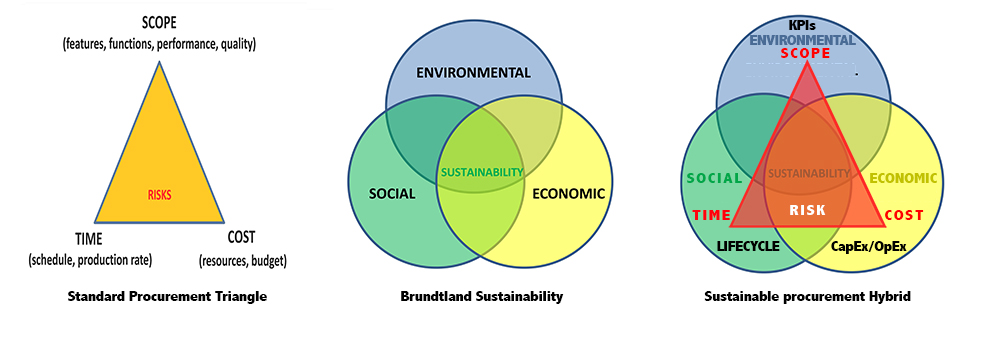

Sustainable procurement is the process of adopting procurement strategies and making decisions in a way that supports wider social, economic and environmental factors.

In 2006, the Sustainable Procurement Task Force defined sustainable procurement as:

| A process whereby organisations meet their needs for goods, services, works and utilities in a way that achieves value for money on a whole life basis in terms of generating benefits not only to the organisation, but also to society and the economy, while minimising damage to the environment. |

Sustainable procurement assesses value for money in terms of the wider benefits to society, the economy and the environment as well as the narrower benefits of the procuring organisation. This might include consideration of lifecycle impacts, environmental impacts, social impacts, and so on. These extrinsic cost considerations are factored into decisions alongside the conventional procurement criteria of price, quality, time, and so on (see Selection criteria for more information).

Some of the advantages of sustainable procurement include:

- Long-term efficiency savings.

- A more efficient and effective use of natural resources.

- Encouraging supply chain innovation.

- Reducing the harmful impact of pollution and waste.

- Reducing the impact of hazardous substances.

- Providing an incentive to supply for the sustainable products market.

- Key part of an organisation’s corporate social responsibility (CSR).

In construction, sustainable procurement might involve consideration of the environmental, social and economic consequences of: :

- Design.

- Non-renewable material use.

- Manufacture and production methods.

- Logistics.

- Service delivery.

- Building use and operation.

- Maintenance and repairs.

- Reuse and recycling options.

- Disposal.

Sustainable procurement involves close collaboration and engagement between all parties in the supply chain, and suppliers’ capabilities to address these factors should be carefully considered during the selection process.

ISO 20400:2017 provides guidance to organisations on integrating sustainability within procurement, and is intended for stakeholders involved in, or impacted by, procurement decisions and processes. (This superseded BS 8903:2010 and is current under its 5 year review process)

In 2019 the EN 15804+A1 2012 was updated to EN 15804+A2 Sustainability of construction works - Environmental product declarations - Core rules for the product category of construction products.

The sustainability objectives of an organisation should be addressed as early in the procurement process as possible. This might include:

- Identifying the business need.

- Defining the sourcing strategy.

- Identifying suppliers.

- Evaluating and awarding.

- Implementing.

- Managing performance and relationship.

- Reviewing and learning.

However, there is no ‘one size fits all’ solution and projects need to consider their unique local environmental, social and economic effects. The geographical location of a project should be considered alongside the objectives of the client and any external stakeholder requirements and the capabilities of the supply chain. Sustainability impacts and risks should be mapped against categories of supply.

By operating the business more efficiently, demand can be kept to a minimum. This requires an organisational link between the procurer and the user.

Innovation should be encouraged and a competitive, sustainable supply chain developed. If a supplier with lower sustainability credentials is selected for other reasons (such as technical capabilities), they should be contractually obliged to develop a programme of work to improve.

An impact measurement process should be adopted, that is linked to the organisation’s strategic sustainability objectives so that meaningful steps can be taken to support their delivery. The organisation should develop an impact measurement tool so that these can be monitored effectively, with the results fed back against corporate objectives. This might be done for example by adopting a Key Performance Indicator (KPI) approach.

CIRIA's Guide to sustainable procurement in construction, published in 2011, set out the following guiding principles to sustainable procurement:

|

- it is the role of the buyer to procure sustainable solutions that offer equal or better value over their life than the traditional alternatives - understand what sustainability outcomes are to be achieved and the reasons for doing this. If they are not being done to mitigate a risk, reduce cost or to achieve a client ambition then perhaps reconsider - understand the supply chain. Buyers should already know where excessive costs may lie but life cycle costs, excessive risk, sustainability impacts and opportunities must also be considered - take ownership of the supply chain and provide guidance regarding sustainability requirements. Work in partnership with suppliers as delegating requirements to tier one suppliers to manage may not be sufficient - understand the client’s sustainability ambitions and the unique circumstances of the project. Develop meaningful and objective measures to address this - do not be tempted to adopt a “one size fits all approach”, each construction project and its associated procurement is unique and will have different drivers and different sustainability risks and opportunities - before buying, re-think/challenge the need for the project/product/service. Work with stakeholders and clients to explore if the need can be met without a procurement taking place - ensure supply chain are involved as early as possible in the project to ensure expertise is harnessed and whole-life value is secured - the process of procurement in construction can range from an in depth market analysis, tender and evaluation process to a simple work instruction to a subcontractor. Irrespective the approach to sustainability requirements should be made clear from the start - ensure supply chain sustainability requirements are contractually enforceable wherever possible. In all cases agree objective measures so that non-compliance is highlighted and corrective actions can be quickly identified - always take time to review lessons learned, record what works and do it again. Share this knowledge to promote better sustainable procurement practices across the industry. |

[edit] Related articles on Designing Buildings

- BREEAM Responsible sourcing of materials.

- Cost led procurement.

- Environmental plan.

- Green Seal.

- ISO 14024.

- Managing the procurement process.

- Material procurement.

- Procurement route.

- Public procurement.

- Recyclable construction materials.

- Sustainable development.

- Sustainable materials.

- Sustainability.

- Sustainability in design: a corporate buzzword or the future of commercial property.

- The sustainability of construction works.

- Whole life costs.

Featured articles and news

Do you take the lead in a circular construction economy?

Help us develop and expand this wiki as a resource for academia and industry alike.

Warm Homes Plan Workforce Taskforce

Risks of undermining UK’s energy transition due to lack of electrotechnical industry representation, says ECA.

Cost Optimal Domestic Electrification CODE

Modelling retrofits only on costs that directly impact the consumer: upfront cost of equipment, energy costs and maintenance costs.

The Warm Homes Plan details released

What's new and what is not, with industry reactions.

Could AI and VR cause an increase the value of heritage?

The Orange book: 2026 Amendment 4 to BS 7671:2018

ECA welcomes IET and BSI content sign off.

How neural technologies could transform the design future

Enhancing legacy parametric engines, offering novel ways to explore solutions and generate geometry.

Key AI related terms to be aware of

With explanations from the UK government and other bodies.

From QS to further education teacher

Applying real world skills with the next generation.

A guide on how children can use LEGO to mirror real engineering processes.

Data infrastructure for next-generation materials science

Research Data Express to automate data processing and create AI-ready datasets for materials research.

Wired for the Future with ECA; powering skills and progress

ECA South Wales Business Day 2025, a day to remember.

AI for the conservation professional

A level of sophistication previously reserved for science fiction.

Biomass harvested in cycles of less than ten years.

An interview with the new CIAT President

Usman Yaqub BSc (Hons) PCIAT MFPWS.

Cost benefit model report of building safety regime in Wales

Proposed policy option costs for design and construction stage of the new building safety regime in Wales.

Do you receive our free biweekly newsletter?

If not you can sign up to receive it in your mailbox here.