Ductwork

Ductwork, ducts, or ducting, are conduits, or tubes, that typically form part of a ventilation system, used to convey air throughout a building. An example of a simple elementary duct is a fireplace chimney, used to convey smoke to the outside. Hard pipes used to transfer water or gas are not classed as ductwork.

Duct design involves planning (laying out), sizing, optimising, and detailing. Ductwork should be among the first items to be considered when designing a new building because of its importance in the overall utility of the building, and the need to integrate complex duct routes with other elements of the overall design. This can be particularly difficult where structural elements pass through building services spaces, such as the downstands of beams, or where ducts have to pass through other elements of the building.

Ducts can be fabricated from a range of materials:

- Galvanised mild steel: This is the most common material used as the zinc coating prevents rust forming.

- Aluminium: This is lightweight and quick to instal. Custom shapes can be easily fabricated as required by the particular design.

- Polyurethane and phenolic foam panels: These are manufactured with aluminium facings on both sides.

- Fibreglass: This provides built-in thermal insulation and sound is absorbed by the interior surface.

- Flex ducts: These are typically made of flexible plastic over a metal wire coil.

Ductwork layouts may be very complex, involving a number of supply and return ducts, that branch to all parts of a building. Typically Heating Ventilation and Air Conditioning (HVAC) ducting will run through voids above a suspended ceiling, supplying and extracting air from the occupied spaces below through diffuser grilles. Air may be drawn or blown through the ducts by fans or by air handling units.

Duct sizes are calculated based on the relationship between air volume, size, air velocity and resistance. The requirements for the provision of air within buildings is set out in Part F of the building regulations, Ventilation.

Air handling units generate noise (and vibration) which can be disruptive, and this can be compounded where ductwork passes between acoustically separate spaces. In this case, acoustic attenuators might be included in the air handling unit or ductwork. In addition, vibration can be generated. This vibration can be isolated by inserting flexible sections between air handling units and ductwork and by isolating the unit from the building structure.

Other components that can be incorporated in ducting systems include:

- Distribution boxes to redirect airflow as required.

- Take-offs, which allow a small portion of the main duct’s flow to be diverted into branch ducts.

- Volume control dampers, which allow for the adjustment of air flow, and may be manual or automatic.

- Smoke and fire dampers where the ductwork passes between fire compartments.

- Turning vanes where there are changes of direction and help minimise turbulence and resistance by guiding the air.

- Access points for cleaning and maintenance.

Before approval, ductwork should be tested to confirm it is adequately sealed.

NB The Scottish Building Standards, Part I. Technical Handbook – Domestic, Appendix A Defined Terms, defines a duct as: ‘…the structure, trunking, or casing, with any apertures, enclosing a passage, other than a flue, used solely for conveying air, gases, or refuse.’

The 2018 International Residential Code (IRC), published by the International Code Council (ICC) defines a duct system as: ‘A continuous passageway for the transmission of air that, in addition to ducts, includes duct fittings, dampers, plenums, fans and accessory air-handling equipment and appliances.’

[edit] Related articles on Designing Buildings

- Air conditioning.

- Air handling unit.

- BSRIA study: The market for European Field Devices.

- Building services.

- Cooling systems for buildings.

- Electrical control systems.

- Flexible ductwork.

- Heating.

- HVAC.

- HVAC balancing.

- Mechanical, electrical and plumbing MEP.

- Mechanical ventilation of buildings.

- Pipework.

- Plant room.

- Raised floor.

- Safe ductwork - Loss Prevention Standard (LPS 2084).

- Thermal comfort.

- Underfloor air conditioning at London Grade II listed landmark.

- Valves.

- Ventilation.

- Vertical riser.

Featured articles and news

Government consultations for the summer of 2025

A year of Labour, past and present consultations on the environment, the built environment, training and tax.

CMA competitiveness probe of major housing developers

100 million affordable housing contributions committed with further consultation published.

Homes England supports Greencore Homes

42 new build affordable sustainable homes in Oxfordshire.

Zero carbon social housing: unlocking brownfield potential

Seven ZEDpod strategies for brownfield housing success.

CIOB report; a blueprint for SDGs and the built environment

Pairing the Sustainable Development Goals with projects.

Types, tests, standards and fires relating to external cladding

Brief descriptions with an extensive list of fires for review.

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

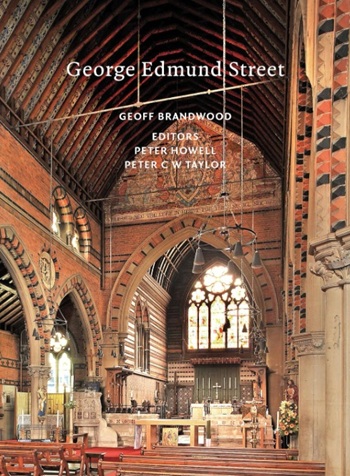

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Comments

Air duct cleaning units produce commotion which can be problematic, and this can be aggravated where ventilation work goes between acoustically separate spaces. For this situation, acoustic attenuators may be incorporated into the air taking care of unit or ventilation work.