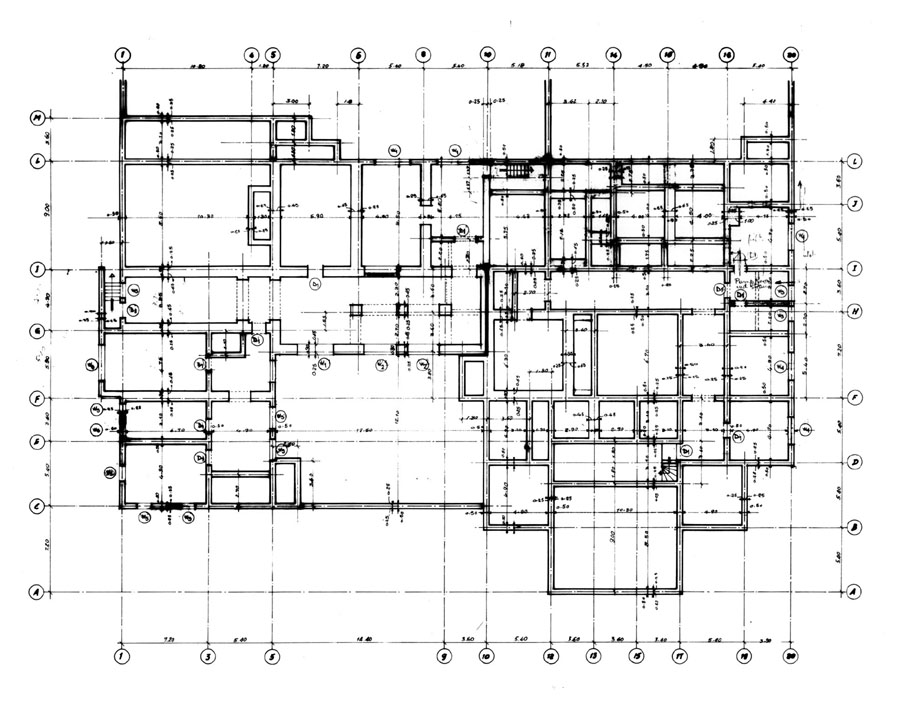

Working drawing

Contents |

[edit] What is production information?

Production information is '...the information prepared by designers, which is passed to a construction team to enable a project to be constructed' (ref. CPIC The importance of production information). Production information is incorporated into tender documentation and then the contract documents for the construction works.

Production information may include:

- Drawings, such as working drawings.

- Specifications.

- Bills of quantities or schedules of work.

[edit] What are working drawings?

Working drawings provide dimensioned, graphical information that can be used; by a contractor to construct the works, or by suppliers to fabricate components of the works or to assemble or instal components. They may include architectural drawings, structural drawings, civil engineering drawings, mechanical drawings, electrical drawings, and so on.

Traditional working drawings consist of two-dimensional orthogonal projections of the building or component they are describing, such as plans, sections and elevations. These may be drawn to scale by hand, or prepared using Computer Aided Design (CAD) software.

However, increasingly, building information modelling (BIM) is being used to create three-dimensional representations of buildings and their components for construction. This may be described as a virtual construction model (VCM) and can comprise a number of different models prepared by different members of the project team.

NB Roles in construction projects: analysis and terminology, by Hughes, W. and Murdoch, J. R, published in 2001 by the University of Reading, suggests that working drawings is: ‘A term that used to be common but seems to have fallen into disuse, describing information produced by designers for builders.’

[edit] How should working drawings be prepared?

Working drawings may include title blocks, dimensions, notation and symbols. It is important that these are consistent with industry standards so that their precise meaning is clear and can be understood. Specification information can be included on working drawings or in a separate specification, but information should not be duplicated as this can become contradictory and may cause confusion.

The scale at which drawings are prepared should reflect the level of detail of the information they are required to convey. Different line thicknesses can also be used to provide greater clarity for certain elements.

It is important that the purpose of the drawings and the people that will use them are considered. Working drawings might be prepared for; statutory approvals, for contractors to plan the construction works, to provide instructions on site, for the procurement of components, for the preparation of shop drawings, for the appointment of subcontractors and so on.

Drawings must be structured carefully so that they convey necessary information to carry out particular parts of the works. To give greater clarity, they may be separated into packages, so that information is specifically tailored to separate parts of the works, specific components, or separate suppliers or trades.

It may be necessary to produce some packages earlier than others, for example, for items with long manufacturing times such as switchgear, chiller units, lifts, escalators or bespoke cladding systems, or for front-end construction such as service diversions, demolition, setting out details, underground drainage, piling and groundworks.

Working drawings may be updated when the works are complete to show ‘as constructed’ information, reflecting changes to the works that may have occurred during the construction process.

The quality of working drawings is extremely important. Unless it is prepared and co-ordinated properly, there will be disputes and delays on site, and costs will be incurred. Common problems with working drawings include:

- Poor co-ordination of information.

- Errors and omissions.

- Information not getting to the right people.

- Poor presentation.

- Using out of date information.

Carefully prepared working drawings can be very beautiful and the very best have been exhibited as works of art.

[edit] Who prepares working drawings?

Responsibility for the preparation of working drawings will depend on the selected system of procurement and the chosen form of contract. On traditional contracts (and management contracts and construction management contracts), working drawings may be produced by a consultant team, working for the client.

Some specialist elements of working drawings may be produced by specialist contractors, co-ordinated by the lead designer. On other forms of contract, such as design and build, responsibility for preparing and co-ordinating working drawings may lie with the main contractor.

[edit] Related articles on Designing Buildings

- As-built drawings and record drawings.

- Assembly drawing.

- Building information modelling.

- Common mistakes on building drawings.

- Computer aided design.

- Design drawings.

- Detail drawing.

- Drawings.

- Engineering drawing.

- Installation drawings.

- Notation and symbols.

- Production information.

- Projections.

- Scale drawing.

- Shop drawings.

- Technical drawing.

- Technical drawing pen sizes.

- Techniques for drawing buildings.

- Types of drawing.

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

Comments

[edit] To make a comment about this article, or to suggest changes, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.

What scales are used for working drawings?

It depends what the drawings are of and what level of detail is required.