Pressing pause to avoid errors

Contents |

[edit] Introduction

Tom Barton of the Get It Right Initiative discusses how the message that eliminating error significantly reduces costs will be fundamental to the survival of many organisations once we return to normal working practices.

[edit] Addressing error rates

One of the central messages of the Get It Right Initiative’s (GIRI) ongoing campaign to eliminate error in the construction industry is the importance of ‘pressing pause to eliminate error’. Sometimes it is better just to stop and take a moment to check that what we are doing is right.

But what happens when we are forced to stop suddenly, and under conditions in which we might not have access to the people, the information or even the technology that we need, to check what we are doing is right? Unfortunately, when we don’t have all of the necessary data, and we don’t revise the plan properly, we risk making things worse.

Covid-19 presents a huge challenge not only to the country as a whole, but also to our industry. There is absolutely no question that when we resume ‘normal’ working, there will be even more pressure on costs and resources, and GIRI’s message that eliminating error reduces costs significantly will be fundamental to the survival of many organisations. Whilst we are facing monumental uncertainty at the present time, the one thing that we can be sure about is that there will be a huge squeeze on costs and a drive to much greater efficiency.

[edit] The price of errors

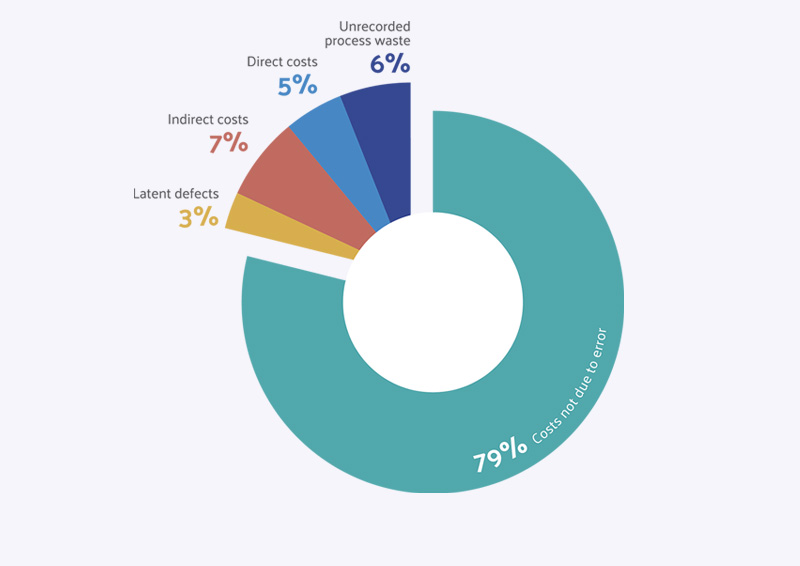

Whilst key studies suggest the direct cost of avoidable error is around 5% of project value, our research among our industry members and their supply chains, both in the UK and internationally, revealed that the true figure is a great deal higher.

When unrecorded process waste, latent defects and indirect costs are included, the situation gets much worse. Estimates of the total cost of errors range between 10% and 25% of project cost or between £10–25 billion per annum across the sector.

When many sites have been closed for an extended period, the consequent disruption and lack of continuity is likely to create conditions in which error frequency will increase. We anticipate that the restart has the potential to cause a spike in error - exacerbating the 10 root causes of error that we identified in GIRI’s Strategy For Change report, as well as creating new causes.

GIRI members have said the main challenges they predict for the restart are:

- How they will manage and motivate staff.

- The underpricing of future works, or the ‘race to the bottom’.

- Sustainability of supply chains.

- Reduced productivity.

- The legal implications of delays.

- The potential loss of competence.

Some of the issues that the industry anticipates once work starts again in earnest are:

- Availability of materials and the potential for inappropriate or lower quality substitutions.

- Adapting to new ways of working

- Unknown errors that might have arisen due to the loss of face-to-face communications.

- Incomplete work that might take time to be identified are just.

[edit] Actions to take

So what can we do to address these issues, and is technology the answer?

While technology has a part to play, there are many other steps that we can take that will contribute to and support the drive to eliminate error.

Our research shows that many of the root causes relate to design; this is not because we have poor designers but because our culture does not enable designers and constructors to work together in a way which eliminates error.

GIRI’s Guide to improving value by reducing design error sets out 12 ways the industry can work to reduce error during the design process. These recommendations resonate almost perfectly with those who urged the industry to use this time to engage engineers ahead of the curve and allow schemes to be delivered more efficiently and effectively.

Now is the perfect time to take stock of what we are doing, reflect on how we are doing things and learn what we can do to improve them. The industry must seize the moment and press pause; we need to change. We cannot afford not to improve the way we do things.

This article was originally published on 21 May 2020 under the title, Pressing pause to avoid error has never been more important. It was written by Tom Barton, Executive Director, Get It Right Initiative and appeared on the Civil Engineering portion of the ICE website.

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

- Articles by ICE on Designing Buildings Wiki.

- A guide to improving value by reducing design error

- Adversarial behaviour in the UK construction industry.

- Conflict avoidance.

- Construction disputes.

- Contract claims.

- Defects.

- Delays on construction projects.

- Disruption claims in construction.

- International research into the causes of delays on construction projects.

- Resilience.

- The Get It Right Initiative

Featured articles and news

CIOB report; a blueprint for SDGs and the built environment

Pairing the Sustainable Development Goals with projects.

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.