Structural steelwork

Contents |

[edit] Introduction

Steel is an alloy of iron and other elements such as carbon. It is one of the most commonly used materials used in the construction industry due to its proven strength and durability. Steel construction has many advantages; an excellent strength-to-weight ratio, the ability to join metals together easily, the ability to form efficient shapes, and so on.

Structural steelwork is generally used to form a the 'skeleton' frame of a building or other built asset, typically consisting of columns and beams which are riveted, bolted or welded together.

There are a number of different forms of structural steelwork. Some of the more common forms are described below.

[edit] Standard hot-rolled sections

Hot-rolled steel is commonly used to form steel beams and columns on construction projects. They are created by passing heated steel between large rollers, which deform it into the required shape, such as; H, I, W, S, C, angles, tubes, and so on.

The standard sections available for use in structural steelwork are given in:

- BS 4-1: 2005 – Structural steel sections. Specification for hot-rolled sections.

- BS EN 10210-1: 2006 – Hot finished structural hollow sections of non-alloy and fine grain steels.

- BS EN 10056-1: 1999 – Specification for structural steel equal and unequal angles.

Common terminology of steelwork sections include:

- Flange: The top and bottom horizontal elements of the 'I'. This resists most of the bending moment experienced.

- Web: The vertical element. This resists shear forces.

- Root radius: The radius of the weld point at which the flange meets the web.

- Toe radius: The radius of the outside edge of the flange.

Typical standard steelwork sections include:

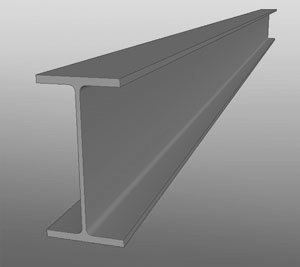

[edit] Universal beam (UB)

This is a beam with an 'I' or 'H'-shaped cross-section that comes in a variety of standard sizes. It is a very efficient form for carrying bending and shear loads in the plane of the web.

The standard method for specifying the dimensions of a standard hot-rolled steel section includes using initials to designate the type of section. For example:

'UB 203 x 133 x 25' – A universal beam of nominal dimensions 203 mm deep, 133 mm wide, and weight 25 kg/m.

[edit] Universal column (UC)

This is a column with an 'I' or 'H'-shaped cross-section that comes in a variety of standard sizes. Unlike a universal beam, the UC's width is roughly equal to their depth.

Dimension specification example:

'152 UC 23' – A universal column of nominal dimensions 152 mm wide, 152 mm deep, and weight 23 kg/m.

[edit] Joists

Joists are used to support the floors or roof of a building. A steel joist must be designed to withstand forces and stress while minimising weight, space requirements, and material costs. Different types of joist designs are available based on loading and mounting configurations. Open-web steel joist (OWSJ) consists of two parallel members, or chords, with a repeating, triangular web structure located between the chords.

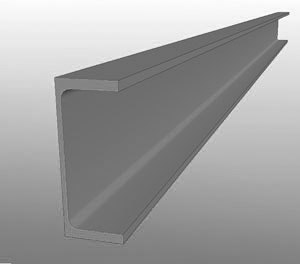

[edit] Channels

Channels are also known as parallel flange channels (PFC) or a 'C-section'. These are commonly used for columns, lintels above doors, or as a beam supporting floor joists.

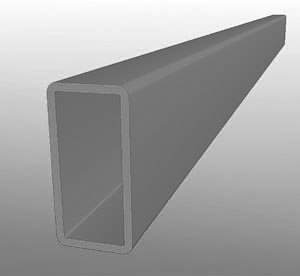

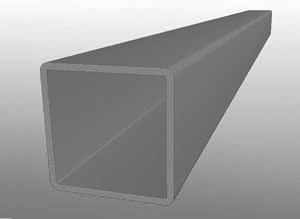

[edit] Hollow sections

These are typically rectangular hollow sections (RHS) or square hollow sections (SHS). They are used less often than UCs and UBs because they are more difficult to bolt to other beams or members. Dimension specification example:

'250 x 150 x 5 RHS' – An RHS of nominal dimensions 250 mm wide, 150 mm deep, and 5 mm thick.

'250 x 250 x 5 SHS' – An SHS of nominal dimensions 250 mm wide, 250 mm deep, and 5 mm thick.

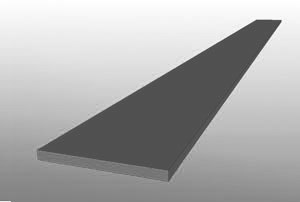

[edit] Flat sections

Where a connection between two beams is required, flat sections may be used. When welded along the top or bottom length of a beam they can add considerable strength.

Dimension specification example:

'40 x 30 flat' – A flat section of nominal dimensions 40 mm wide and 30 mm thick.

In compound sections, flat sections are often cut smaller as 'plates' to be welded to joists or other steel sections.

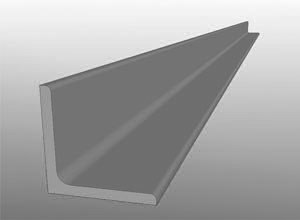

[edit] Rolled steel angle (RSA)

These can be either equal angles or unequal angles and are often called 'L-shape' sections.

Equal angles have legs of the same length and are most often used for balconies, stairs, concrete supports, and platforms.

Dimension specification example:

'50 x 50 x 8 RSA' – An RSA section of nominal dimensions 50 mm wide, 50 mm deep, and 8 mm thick.

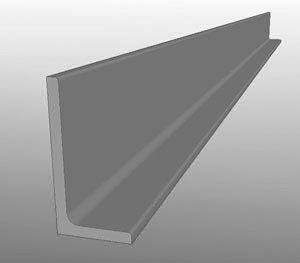

Unequal angles have a longer vertical leg. They are used in many of the same applications as equal angles but are often also used as lintels as they have greater loading capabilities.

Dimension specification example:

'50 x 30 x 5 RSA' – An RSA section of nominal dimensions 50 mm deep (longer leg listed first), 30 mm wide, and 5 mm thick.

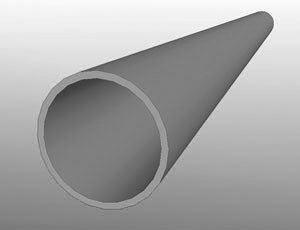

[edit] Circular hollow section (CHS)

These are often used as columns and braces steel frame structures. They are listed with their diameter and wall thickness. For example:

'60.3 x 5 CHS' – A CHS section of nominal dimensions 60.3 mm in diameter and 5 mm thick.

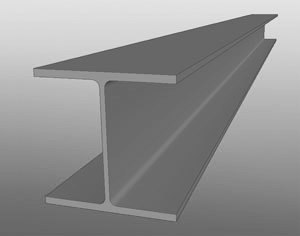

[edit] Compound sections

Compound sections are produced by welding together standard sections. They can be used for designs that specify very high loads and long spans that would be unsuitable for standard sections alone. Common variations include:

- Beam or column compound: A standard joist, beam or column section with a steel plate welded above and below.

- Channel compound: These can be either a standard channel welded back-to-back; back-to-back and welded with flange plates above and below; or welded toe-to-toe.

- Gantry girder: These are a combination of standard channel, joist and plate sections welded together.

[edit] Open web beams

These are commonly used for structures that require long spans with light-to-moderate loading. Deflection is resisted by the relative increase in depth, and structural dead loads can be reduced by the voids that are included in the web.

The different types of open web beam include:

- Perforated beam: A standard beam section with circular voids cut through the web. The voids are spaced to suit the required load.

- Castellated beam: An oxy-acetylene torch is used to cut a standard beam section in two along the web. Each section's projections are then welded together forming a beam that is twice as deep as before.

- Litzka beam: Similar to a castellated beam, but the overall depth is increased further by welding spacer plates to the projects.

[edit] Lattice beams

These are an alternative to open web beams and can be used for spans of up to 15 m with high depth-to-weight ratios. Two of the different types of lattice beam include:

- Plate girder: This is typically an I-beam made up from separate structural steel plates which are welded, bolted or riveted together to form the vertical web and horizontal flanges of the beam, filled with a steel bar laced web.

- Tubular lattice: This has top and bottom tubular booms connected by tubular bracing.

For more information, see Girder.

[edit] Related articles on Designing Buildings Wiki

- 8 reasons why structural steel frames are advantageous for any building project.

- Braced frame.

- Concrete-steel composite structures.

- Concrete vs. steel.

- Failure of cast iron beams.

- Failure of metals.

- Galvanised steel.

- Gantry.

- Girder.

- Guidance for construction quality management professionals: Structural Steelwork.

- Gusset.

- Installing fire protection to structural steelwork (GG 85).

- Long span roof.

- Major cast metal components.

- Metal fabrication.

- Rivet.

- Skeleton frame.

- Stainless steel vs. galvanised steel.

- Steel Architecture: the designed landscape of modernity.

- Steel frame.

- Structural steelwork: a quality perspective.

- Super-strength steel structures.

- Tube structural system.

- Weathering steel.

[edit] External resources

- Handbook of Structural Steelwork.

- Polsteel - Steel sections

- 'Building Construction Handbook' (6th ed.), CHUDLEY, R., GREENO, R., Butterworth-Heinemann (2007)

- 'Introduction to Civil Engineering Construction' (3rd ed.), HOLMES, R., College of Estate Management (1995)

Featured articles and news

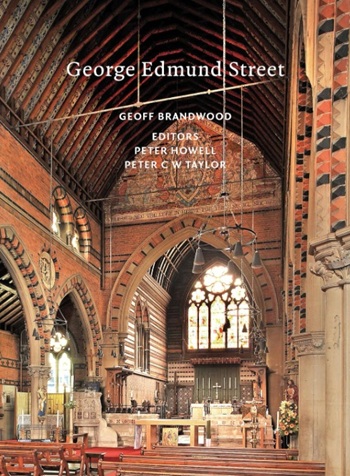

One of the most impressive Victorian architects. Book review.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.