Flanges in construction

|

|

[edit] Introduction

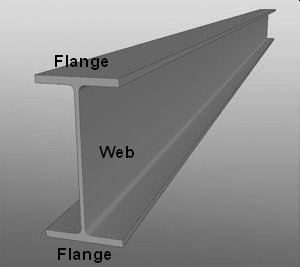

A flange is a projecting ridge, rim, collar or ring on an object such as a column, beam, pipe and so on that provides additional strength or stiffness or additional surface area for the attachment of, or to, another object. For example, flanges may be used to strengthen beams, or to connect or terminate pipes.

Where another object is to be attached, a flange may include bolt holes.

[edit] Pipework flange

Flanges are used in pipework systems for connecting and attaching pipes, valves, pumps, and so on. As an external or internal ridge, or rim, flanges are usually designed to interface sections of pipe and enable easy assembly and disassembly.

Typically, a flange is a forged or thrown ring of stainless steel that is welded or screwed to another component in the system. To create a flanged joint in a pipe system, two connecting pieces with flanges at the end are bolted together, with a seal provided by a gasket between them.

The dimensions of flanges are determined by the size of the pipe as well as the pressure class required for the application. The pressure class ratings that flanges are designed to are typically: 150 lb, 300 lb, 400 lb, 600 lb, 900 lb, 1,500 lb, and 2,500 lb. There are many different flange standards worldwide, with organisations such as ASME, MSS, and API publishing standards.

There are numerous types of flanges, including:

- Blind: This is a plate for covering or closing the end of a pipe, mainly used as part of high pressure weight applications.

- Expander: The non-flanged end is larger than the flanged end. This is used to change the size of a pipe run.

- Groove/tongue: This combination of a raised ring (tongue) and depression (groove) align together precisely.

- High hub blind: This is a simple round plate without a centre hold.

- Lapped joint: Used on applications with lap joint stub ends or lapped pipes, typically where cleaning or inspection is regularly required.

- Orifice: Typically used with orifice metering systems for gauging liquid and gas flow rates.

- Plate: Similar to a gasket, typically used in applications made from casting.

- Reducing: Used in applications with different pipe diameters.

- Ring type joint: A metal ring with a hexagonal groove compressed to a flange to form a seal.

- Slip-on: This flange slips over the pipe and is welded at the top and base side.

- Socket weld: Pipes are inserted into the sockets of flanges and welded for smooth flow. This tends to be used for smaller pipes.

- Spectacle: Comprises two discs attached with the help of a small metal (usually stainless steel, alloy steel, etc.) section.

- Square: A square-shaped flange.

- Threaded: This flange is fixed to a pipe using threads rather than welding, and so are more commonly used for low pressure applications.

- Weld neck: This helps transfer stress from flange to pipe, and is suitable for high pressure applications.

- Weldo/Nipo: A combination of weld neck flange and a nipolet (a one-piece fitting for valve take-offs, drains and vents).

[edit] Related articles on Designing Buildings

Featured articles and news

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”