Inmos Microprocessor Factory

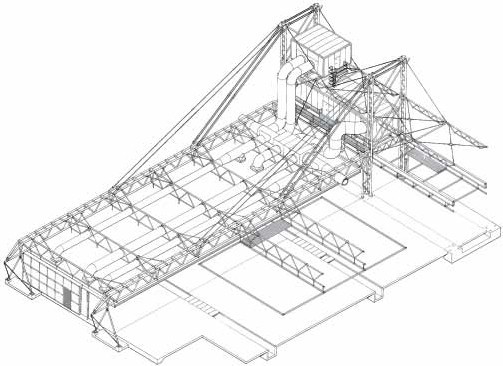

The concept for INMOS is large, column-free flexible and universally serviced open operational spaces with a central circulation spine and central meeting space at its heart.

The fast-track nature of the project required the design to be responsive to any site and capable of being built in a range of sizes. The factory is located at Newport, Gwent, close to major transport routes. The 8,900 m2 building provides office and ancillary space, plus facilities for microchip wafer production.

Speed of design and construction were critical factors. The single-storey steel structure was conceived as a kit of parts, with maximum off-site prefabrication allowing the building to be erected bay by bay. The structure is a tubular steel assisted span-tension structure, supported by tension tie rods from the spine towers. This system provides uninterrupted column-free spaces for maximum internal flexibility. The roof is fabricated from 6m span steel decking with thermal insulation and a five-layer roof membrane. The external walls are based on a system of standardised mullions incorporating various infills: single glazing, double glazing, translucent or opaque panels. Wall performances and finishes can be varied as required. The initial design includes double glazing for office areas and solid insulated sandwich panels for production areas.

The building features a central circulation/service spine with internal wings for specialised activities. The spine is 7.2 m wide and 106 m long and acts as an internal street, wide enough for vending machines, public telephones, seating, meeting places, planted areas and waiting areas. Services from the plant room – hot and cold water, chilled water, compressed air, etc – run at high level in this main spine. The building is extendable along the spine in 13 x 36m bays. Offices and restaurants are on the south side of the spine and the clean room production area to the north. Production wastes are collected in linear floor trenches and supply services are distributed on service walls. A large clean room facility and shipping and receiving bays occupy the north side of the spine. The south side has one bay omitted, providing a landscaped courtyard between the offices and the restaurant. Assembly labs and main piped services plant room occupy three western bays of the south face.

Project information:

- Place: Newport, Wales

- Date: 1982 - 1987

- Client: Inmos Ltd

- Area: 8,900 m²

- Architect: Richard Rogers Partnership

- Structural Engineer: Anthony Hunt Associates

- Services Engineer: YRM Engineers

- Quantity Surveyor: GA Hanscomb Partnership

- Main Contractor: Laing Management Contracting Ltd

Awards:

- The Structural Steel Design Award, 1982

- Eurostructpress Award, 1983

- Financial Times Architecture at Work Award Commendation, 1983

- Constructa-Preis for Overall Excellence in the Field of Architecture, 1986

--Rogers Stirk Harbour + Partners 14:09, 12 March 2015 (UTC)

Featured articles and news

Managing building safety risks

Across an existing residential portfolio, a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.