Aluminum Composite Panels (ACP) on buildings

|

Contents |

[edit] Introduction

Aluminium Composite Panels are made by laminating an intermediate layer of non-aluminium core between the top and bottom layers of a thin aluminium panel. ACP panels can be further coated with Polyvinylidene fluoride (PVDF) or polyester paint. Total thickness of panels varies from 3 mm to 6 mm, including adhesive layers and glues.

ACP panels are used on the interior and exterior of buildings, often with coloured finishes.

[edit] Features of ACP panels

Aluminium Composite Panels (ACP) offers a wider range of options for builders and architects:

- Durability: ACP laminate is weather resistant, stain resistant and highly durable. Even after exposure to sunlight and weather changes, the panels retain their colour, shape and size, making them ideal for all seasons. They are also soundproof, allowing sound to be deducted from the outside environment.

- Safe to use: Because aluminium is a very good insulator, ACP panels are fire resistant. They do not emit gases or fumes and are safe for internal cladding.

- Economical: Aluminium composite panels are one of the most cost effective and economical materials on the market. They are easy to use, durable and provide the perfect answer for commercial establishments. According to experts, ACP panels offer high quality thermal comfort and reduce energy consumption, thus reducing your electricity bill. They can be used in a variety of shapes and sizes, minimising waste.

- Hassle-free installation: ACP laminates are easy and undemanding to install and can create some extraordinary designs that may be difficult or impossible to recreate with other materials.

- Easy to maintain: ACP laminates require low and hassle-free maintenance and will retain their shape and texture for a long time. Dirt or dust particles can be removed from its surface by simply wiping with a cloth.

[edit] Advantages of using ACP sheet

Below are some of the main advantages:

- The panel has the qualities of light weight, durability, rigidity and strength.

- Another added benefit is its strength-to-weight ratio.

- ACP panels can be cut into various sizes to suit your requirements and the material is highly adaptable.

- The PVDF coating makes it fire and weather resistant, protecting the material from fading and staining.

- ACP panels have a perfectly uniform surface without any deflection or distortion and are resistant to breakage.

- These panels are easy to install and maintain, easy to recycle, and therefore environmentally friendly.

- Aluminium composite panels provide excellent thermal and acoustic insulation.

- They are also weather resistant and UV resistant.

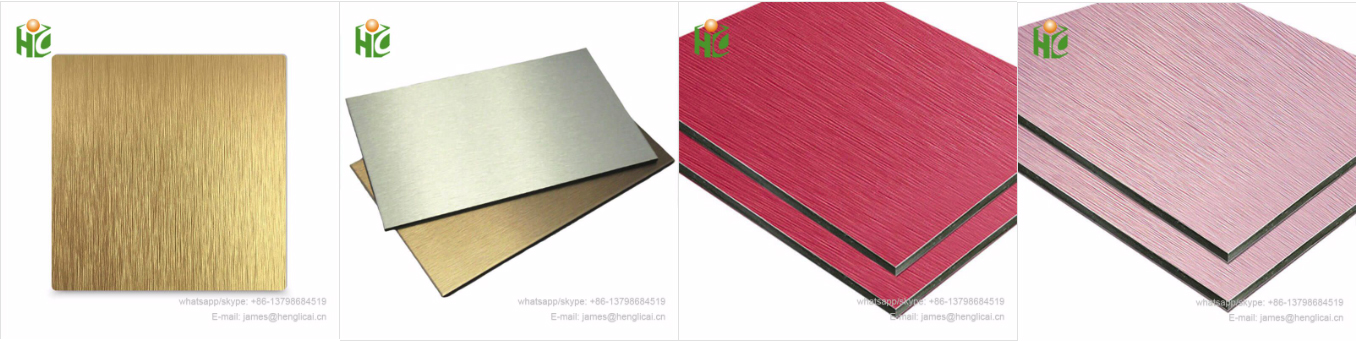

- These panels are available in a wide range of colours and finishes, from standard colours to high-gloss, matte and metallic finishes.

[edit] ACP Sheet Applications

ACP is an important part of the interior and exterior decoration of hotels, hospitals, subway stations and other buildings, were it can be uses as:

- Exterior and interior of buildings and corporate housing

- Cabinets, closets and modular kitchens

- False ceilings

- Wall panels

- Machine and equipment coverings

- Signs and signage

- Container construction

NB Click here for information about ACM cladding and the Grenfell Tower fire.

[edit] Related articles on Designing Buildings

- ACM cladding.

- Aluminium.

- Aluminium decking.

- Cast iron.

- Copper.

- Difference between cast iron and wrought iron.

- Failure of metals.

- Flashing.

- Galvanised steel.

- Iron.

- Lead.

- Lead in construction.

- Major cast metal components.

- Metal.

- Metal composite panels.

- Metal fabrication.

- Metal roofing.

- Potash.

- Stainless steel.

- Structural principles.

- Structural steelwork.

- Types of metal.

- Types of steel.

- Weathering steel.

- Zinc.

Featured articles and news

Delayed, derailed and devalued

How the UK’s planning crisis is undermining British manufacturing.

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.