Planning construction projects

Damian Bucke, Aphex and Costain Skanska JV, discusses the importance of communication, collaboration and simplicity when planning construction projects.

Contents |

[edit] Introduction

"Plans are nothing; planning is everything” is a famous quote by former US President Dwight D Eisenhower (1890-1969). While some people may question whether plans really are nothing, many more would understand and agree with Eisenhower’s sentiment and his emphasis on the importance of the planning process over the plan itself.

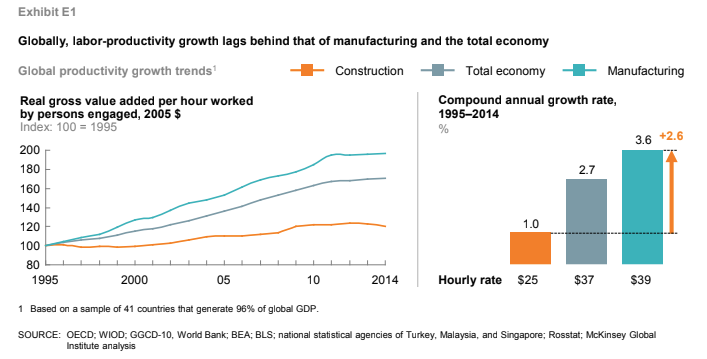

As the graph above demonstrates, over the past number of decades the construction industry’s productivity has been static, with a concerning lack of growth.

This trend, and an increasingly competitive market, has prompted the construction industry to shift its focus on improving productivity, with high-profile initiatives such as ICE’s Project 13 formed to tackle the issue.

The initiatives set out by Project 13 aim to disrupt the industry, boosting certainty and productivity in delivery and improve whole life outcomes in operation.

And as reported in the October 2018 edition of NCE, with the construction industry currently 21% less productive than the rest of the economy, there really is no time to waste.

[edit] The adoption of digital technology

The under-use of digital technology within construction has been widely documented and can be understood as a key reason for lower productivity levels. But in recent years, there's been a surge of innovation in this area with a huge stream of apps and new software options open for companies to explore.

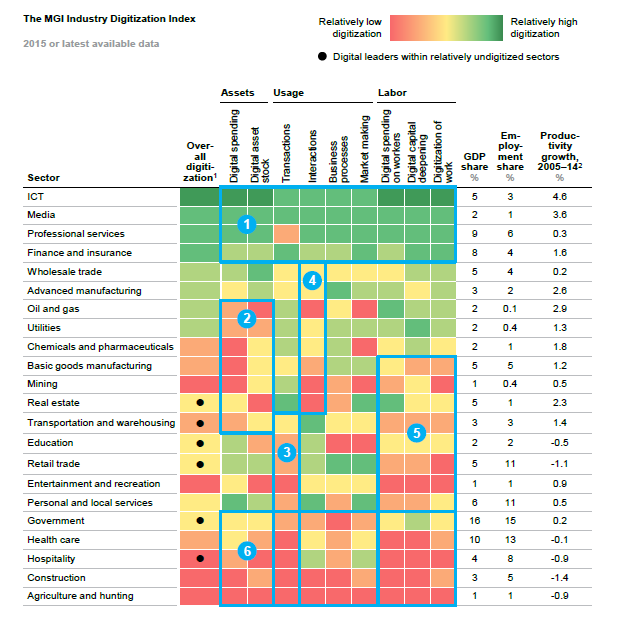

According to McKinsey Global Institute’s Digitisation Index - as seen below - construction is one of the least digitised industries in the world, but for how long.

At a project level, robust short-term planning remains one of the most reliable and effective methods for a project to increase both efficiency and productivity for maximum programme and commercial benefits.

As Eisenhower inferred, simply having plans in place will not solely bring about these improvements, as this relies ultimately upon the quality of the planning within those plans.

Fortunately, there are some reliable methods for ensuring short-term plans are produced with the quality required to improve production.

[edit] Collaboration

On a construction project, collaboration is key. The importance of knowing, and fully understanding, how your planned works will interface with the works of others planning their own works around you cannot be understated.

Not only does effective collaboration prevent needless waste through mitigating the likelihood of two workgroups planning work in the same location at the same time, but more importantly it prevents the need for last-minute site changes, which is often the root cause of many safety incidents.

For some time, the Lean Construction Institute has led the way in developing collaborative processes, and its website offers further valuable tips on improving collaboration on construction sites.

[edit] Remove constraints

Activities will nearly always have constraints of some sort that, unless addressed, will prevent the activity from being achieved.

Design and documentation for safety, environmental, and quality are the most common forms of documentation constraints that could affect the success of an activity if they're not in place prior to commencing the activities.

With construction being the fluid industry that it is, there will always be situations that arise on a project that require urgent changes to documentation, design, or methods of working.

In such instances, amending the documentation as expediently as possible is vital. However, not having this documentation in place for the activities that aren't subject to late change will be down to poor planning.

Maintaining trackers for documentation can help ensure timely production of documentation to prevent delay.

[edit] Learning from failure

Root cause analysis is a technique commonly used in construction, however, it's more often used to determine how health and safety incidents occurred and to ensure reoccurrence is prevented.

Similarly, grouping and analysing failed activities provides project teams with invaluable data that can be used to identify the common reasons that activities are failing to prevent reoccurrence as much as possible to help increase the overall reliability of the plans.

[edit] Keep it simple

For a plan to be effective, people have to be able to follow the plan. Therefore, adding unnecessarily complicated information should be avoided to prevent confusion.

It's also worth remembering that some people who need to be aware of the plan may find the traditional Gantt or bar chart formats confusing, and other formats should be considered.

Other formats that could be considered include visual plans with activities drawn onto site sketches to show the activities planned to occur on a particular day or week.

Visual plans are especially successful for site teams, and this format is strongly recommended in such circumstances.

Another simple format is a daily list of activities, broken down by location, team, discipline, or a mixture of these to suit the project requirements.

Whichever format is adopted, the most important thing is that a plan should always be clear, concise and as simple as it can be.

This article was originally published here on 11 Oct 2018 by ICE. It was written by Damian Bucke, chief product officer at Aphex and senior planner at Costain Skanska JV.

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.