Biocement

|

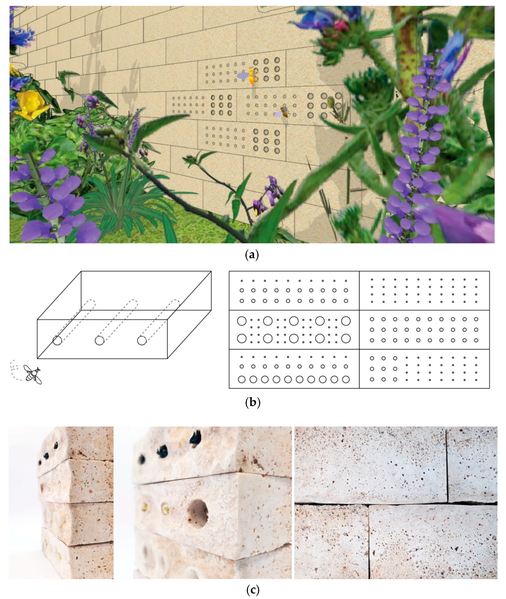

| This series of figures illustrates a biocement application in bee nesting. Figure (a) shows a virtual diagram of the biocement brick and housing area. Figure (b) shows the cross section of the design and the holes the bees can nest in. Figure (c) shows the prototype of the bee block made from biocement. |

Contents |

[edit] Introduction

Biocement is a product that stimulates native soil bacteria to connect soil particles through a process known as microbially induced calcite precipitation (MICP). It uses microorganisms to produce a strong and renewable building material with minimal impact on the environment. Compared to the production process of traditional cement, biocement uses less energy and generates less CO2 emissions.

[edit] Development of biocement

MICP produced biocement is shipped as a dry powder that is mixed with water. This process - referred to as biocementation - results in a product that may serve as an appropriate substitute for cement in construction projects.

Using bacteria to generate calcium carbonate precipitation incorporates several chemical reactions, including the hydrolysis of urea. This has become one of the most commonly used processes for the production of biocement in terms of cost and time.

There are several suggested uses for MICP biocement, including crack remediation, concrete corrosion moderation and biogrout (a soil improvement method) production.

[edit] Self-healing biocement

Biocement has also been used in self-healing applications. In this procedure, water is used to activate the bacteria to react materials. for sealing cracks, filling pores and bonding surfaces with bacterial calcium carbonate deposits. It offers durability, leak prevention and extends the service life of concrete structures.

Oxygen is consumed by the bacteria to convert calcium into limestone, which closes the crack and helps in the prevention of the corrosion of steel reinforcement due to water ingress.

This technique may prove useful in the preservation or conservation of structures built from porous materials. Buildings, monuments and other vulnerable objects may be especially susceptible to moisture, chemicals, pollutants and other contaminants that have an impact on their strength and appearance. The success of the process may depend on several environmental factors, including weather conditions and pH levels.

[edit] Biocement bricks

Biocement bricks are another product that can be 'grown'. Instead of requiring a significant amount of heat in the production process, these bricks are created by using a bacterial byproduct to fuse sand particles together and form a durable building material.

This technique was developed by bioMASON, a North Carolina company founded by architect Ginger Krieg Dosier. These durable bricks use a combination of biomass, aggregate, renewable nutrients and minerals that are placed into moulds and then treated with a type of bacteria (Sporosarcina pasteurii) that is fed with calcium ions and water. This results in the production of a calcium carbonate shell that can be used to create a 'natural' biocement brick. The process takes less than three days and is said to simulate the actions used by corals.

In a Wired article entitled, How to grow bricks from trillions of bacteria, Kathryn Nave writes: ‘A single bacterial brick takes two to five days to grow, compared with three to five days to make a kiln-fired version. “We can make bricks that glow in the dark, bricks that absorb pollution, bricks that change colour when wet," Dosier says.’

[edit] Related articles on Designing Buildings

- Artificial cement.

- Cement.

- Concrete.

- Cradle-to-cradle.

- Cradle to cradle product registry system.

- Self-healing concrete.

- Self-healing concrete and sweaty roofs: is this the future of buildings?

- Regenerative design.

[edit] External resources

- Kathryn Nave, Wired, How to grow bricks from trillions of bacteria.

Featured articles and news

Do you take the lead in a circular construction economy?

Help us develop and expand this wiki as a resource for academia and industry alike.

Warm Homes Plan Workforce Taskforce

Risks of undermining UK’s energy transition due to lack of electrotechnical industry representation, says ECA.

Cost Optimal Domestic Electrification CODE

Modelling retrofits only on costs that directly impact the consumer: upfront cost of equipment, energy costs and maintenance costs.

The Warm Homes Plan details released

What's new and what is not, with industry reactions.

Could AI and VR cause an increase the value of heritage?

The Orange book: 2026 Amendment 4 to BS 7671:2018

ECA welcomes IET and BSI content sign off.

How neural technologies could transform the design future

Enhancing legacy parametric engines, offering novel ways to explore solutions and generate geometry.

Key AI related terms to be aware of

With explanations from the UK government and other bodies.

From QS to further education teacher

Applying real world skills with the next generation.

A guide on how children can use LEGO to mirror real engineering processes.

Data infrastructure for next-generation materials science

Research Data Express to automate data processing and create AI-ready datasets for materials research.

Wired for the Future with ECA; powering skills and progress

ECA South Wales Business Day 2025, a day to remember.

AI for the conservation professional

A level of sophistication previously reserved for science fiction.

Biomass harvested in cycles of less than ten years.

An interview with the new CIAT President

Usman Yaqub BSc (Hons) PCIAT MFPWS.

Cost benefit model report of building safety regime in Wales

Proposed policy option costs for design and construction stage of the new building safety regime in Wales.

Do you receive our free biweekly newsletter?

If not you can sign up to receive it in your mailbox here.