What makes a responsible construction product manufacturer?

Clearly communicated values. Good quality product information. Comprehensive specification and sales support. Transparency and responsiveness. All of those things, and more, contribute to a manufacturer feeling more like a collaborative partner than simply a product supplier. Overall, it is about culture.

In the last issue of AT Journal (issue 153, Spring 2025), my colleague, Rob Firman, wrote about the relationship between specifiers and product manufacturers (The benefits of specifiers engaging with insulation manufacturers). He talked about how closer engagement between the two can help to deliver more buildable constructions and, ultimately, why the as-built performance we all know is so important.

If a product manufacturer has a good culture, that feeds into positive engagement with design professionals. And it plays a big part in them being seen as responsible. But that culture has to extend past the specification and sales stage.

For many construction product manufacturers, once their product leaves the factory gate, they lose an element of control over how it is used and installed. But that doesn’t mean they stop being a crucial part of helping projects reach a successful conclusion.

For over thirty years I worked for my family’s roofing business. The success of our business often depended on the attitude manufacturers took to working with us, and I’d like to share a little more about that perspective to help round out the picture we started painting in the last issue.

When I say I ‘worked’ for the family business, it’s more accurate to say that I ran it for the majority of those 32 years. Five years after starting out as a labourer, I became company director. It likely won’t come as a surprise that being responsible for a roofing firm is a stressful job. It was never possible to completely switch off. Weekends, holidays – my phone would be on and I always needed to be available.

In part, being unable to switch off was because I took pride in our work and wanted to make sure our customers were looked after. We worked mainly on industrial roofs, including for some big-name companies. Alongside that, we did church roofs and listed buildings, and also school work with local authorities.

Doing a good job was important. Not just so our customers would come back to us, or recommend us to others, but because I cared about the quality of what we offered. And when you stake your name on quality, and come to be relied upon for that, you need others in the supply chain to support you.

So, what is it like when a manufacturer lets you down? There was one occasion when we were using a particular waterproofing product, and the manufacturer started coming to site. They told us they needed to carry out temperature checks. We asked if there was a problem and they told us no. Not long after that, strong winds caused the roof to rip off.

That year, we had used the same product on 36 different roofs, and the same thing happened to every single building. The waterproofing manufacturer paid compensation and redid the work, but that was beside the point. Quite simply, they lied to us, and those lies caused us a lot of reputational damage with our clients that was hard to recover from.

You can provide consistently good service, but it only takes one negative experience to change how people perceive you. And we had 36 negative experiences happen in quick succession.

The waterproofing manufacturer then simply left the market for that type of waterproofing. For them, they could be seen to have fixed the work and then move onto something else. For us, working in the roofing industry day in, day out, we didn’t have the option of moving on to something else. We had to work hard to try and recover from the consequences of the manufacturer’s dishonest approach.

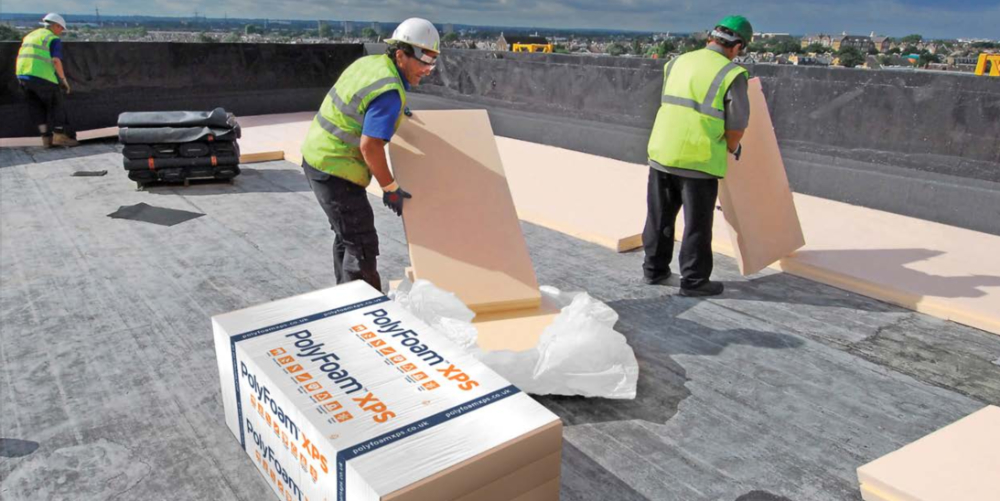

With nearly forty years of experience in the construction industry, I have unfortunately seen a lot of dishonest culture. But I do see signs that things are changing, and I expect greater transparency to become the norm. I hope to see people and organisations being properly held to account for their actions. Being a company director was a stressful way to earn a living. Now, as a Business Development Manager for Polyfoam XPS, I actually enjoy being a member of a team rather than having the responsibility that comes from being a company’s figurehead. It allows me to focus my energy on providing good service and working with our customers to deliver exactly what they need.

I particularly like working with clients who want non-stock items, or something new. Sometimes people don’t really know what they want and we put in a lot of work with them. When the result of that work is an order, it makes the effort all worthwhile. And then the customer tends to stay with us, because we’ve invested time in them and they see that effort.

Four decades is a long time, and I’ve gained a lot of experience in that time. It gives you some perspective. I don’t need to make a name for myself, or try to promise people the earth to win an order.

In all the discussions around competence in the construction industry, we keep hearing about the SKEB principles: skills, knowledge, experience and behaviour. It is true that you can have all the skills, knowledge and experience in the world, but it doesn’t count for much if it is tied to poor behaviour. But I also think the link between experience and behaviour is interesting.

Being out on the road a lot, I meet a lot of young professionals representing other manufacturers who are keen to make a name for themselves. They promise customers whatever is necessary to win an order.

Hopefully, in time, they will learn they don’t need to do that to forge good customer relationships – but manufacturers can also play their part by trying to take off some of the pressure the young reps feel.

Speaking from my experience running a roofing business, manufacturers need to make sure that customers are offered the right solution for their needs, and not just being told what they want to hear. With a responsible approach like that, improvements in competence are bound to follow.

This article appears in the AT Journal issue 154, Summer 2025 as "What makes a responsible construction product manufacturer?" and was written by Gary Ferguson, Business Development Manager (North and Scotland), Polyfoam XPS.

--CIAT

[edit] Related articles on Designing Buildings

- Code for Construction Product Information.

- Considerate Constructors Scheme CCS.

- Construction Products Association CPA.

- CPA and the Code for Construction Product Information launch.

- Grenfell Tower articles.

- Grenfell Tower fire.

- Hackitt review.

- Hackitt review of the building regulations and fire safety, final report.

- Post-Grenfell product code combats misleading marketing.

- Product manufacturers must regain confidence.

- Supplier.

- Supply chain.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”