Plug and play skyscrapers

|

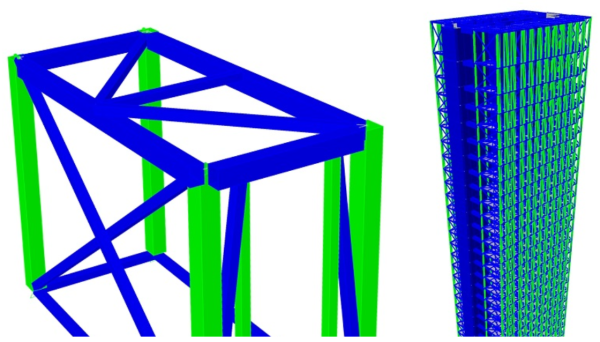

| Typical steel module (left) was modelled in a 40-storey building (right) |

Contents |

[edit] Introduction

Off-site manufacture of ‘plug and play’ modules is fast gaining ground in the housing and plant sectors. What are the engineering challenges for using it for high-rise buildings?

Modular construction, in which complete assemblies – ranging from plant rooms to apartments – are manufactured and tested off-site and then simply slotted into position on-site, is revolutionising construction worldwide.

Benefits include shorter construction, greater safety, reduced waste and higher performance. It comes under various names, including ‘modern methods of construction’ in the UK, ‘permanent modular building’ in the USA, ‘prefabricated prefinished volumetric construction’ in Singapore and ‘modular integrated construction’ in Hong Kong.

[edit] Engineering challenges

However, devising modular systems for high-rise buildings is more technically challenging than those currently used for low- to medium-rise structures, particularly where space is at a premium and strong winds and seismic loading are likely.

Lifting and handling of modules is also a major concern, so reducing module weight is a priority. However, reducing the self-weight may result in excessive tension uplift under strong winds and lead to non-linear behaviour during earthquakes.

In addition, the lateral stability of modular buildings is primarily provided by a reinforced concrete stair and lift core. For high-rise structures, stability can be increased by adding steel outrigger arms to the core and steel edge columns, but analysis of the stresses induced in the modules becomes highly complex.

[edit] Solutions and recommendations

The University of Hong Kong recently carried out a feasibility study for the Hong Kong government on the use of modular construction for high-rise buildings.

Structural schemes for 31–40-storey buildings using commonly-manufactured steel modules were numerically modelled in the Etabs software and analysed against codified critical wind loads.

The results showed that modular high-rise buildings are feasible regarding structural stability – that is, they can satisfy the limitations in top-storey and inter-storey drift due to wind loads.

This however depends on careful design of the core wall layout, core wall thickness and connections between the modules and the core.

Modules with one side directly connected to the core are recommended so that the majority of lateral loads can be transferred to the core by each module independently.

Also, these connections should be designed as pin-ended in the vertical direction. As a lower-bound approach, pin-ended connections were used in the numerical model and were further checked against finite-element analysis using Abaqus in terms of stiffness, load capacity, deformation and stress distribution.

[edit] Higher strength materials

In addition, high-strength steel columns of grades S690 or even S960 can be used for manufacturing the modules to ensure sufficient load-carrying capacity.

For concrete modules, adopting fibre-reinforced concrete walls and/or slabs can help to reduce structural weight to an optimum level.

Authors: Wei Pan, Ray Su, Yancheng Cai and Ben Young, The University of Hong Kong. This article is based on the authors’ briefing article issue 174 CE4 of the ICE Civil Engineering journal. November 2018. Source: https://www.ice.org.uk/news-and-insight/the-civil-engineer/december-2018/plug-and-play-skyscrapers-can-it-be-done

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

- Advanced construction technology.

- Advanced manufacturing.

- BSRIA launches Offsite Construction for Building Services topic guide.

- How to make projects off-site ready.

- ICE articles on Designing Buildings Wiki

- Modern methods of construction.

- Modular buildings.

- Off-site construction.

- Offsite manufacturing.

- Off-site prefabrication of buildings: A guide to connection choices.

- Prefabrication.

- Skyscraper.

- The Institution of Civil Engineers.

Featured articles and news

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.