Microplastics

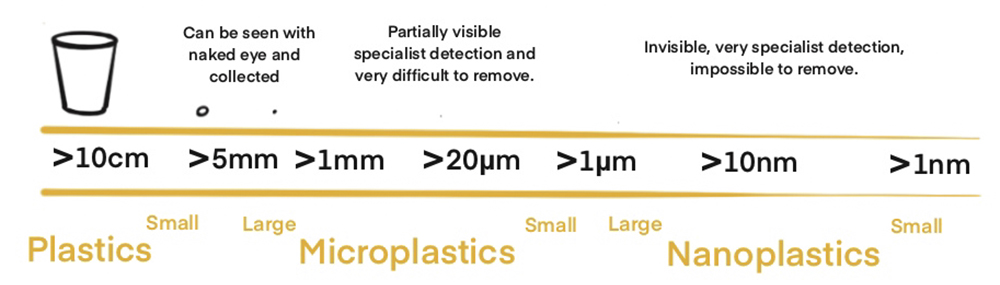

Microplastics (micro-plastics) are small pieces of plastic that are less than five millimetres long or in diameter, these can further be classified, when they are less than a micrometer (or one micron - 1μm which is 1000 times smaller than a millimeter) as nanoplastics.

Microplastics themselves are categorised into two types: Those that are actually designed as tiny particles and intended for commercial use (Primary microplastics) and those that form as a result of the breaking down of larger plastic products (Secondary microplastics). Both types can have significant negative impacts for the environment, wildlife, sea-life, birdlife and humans, the smaller they become the more difficult they are to remove.

Contents |

[edit] Primary microplastics

Primary microplastics are specifically designed for commercial products and used in fertilisers, plant protection products, cosmetics, household and industrial detergents, cleaning products, paints and products for the oil and gas industry. These types of plastics are often used for their abrasion qualities such as in skin treatment in cosmetics, as thickening agents or stabilisers such as in paints or standard cosmetics or for both such as in cleaning products. It is estimated that 145 000 tonnes of these microplastics are used in the EU / EEA each year.

[edit] Microfibres

Microfibres can make up a large majority of micro plastics, they might be classified as primary, because of their specific design but also as secondary because they can occur shedding through washing. Some studies suggest individual items of clothes can release well over 1000 microfibres into water systems through a single wash cycle. Clothing company Patagonia estimated that 40% of these microfibres are not filtered out at wastewater treatment plants, and unlike cotton or wool, these microfibres are not-biodegradable. They are shed from all types of plastic based textile products and include fishing nets.

[edit] Microbeads

Microbeads from many cosmetic products are now banned in the US, Canada, France, New Zealand, Sweden, Taiwan and the United Kingdom. These are plastic particles that measure less than one millimetre in diameter and have been used in a variety of products, for example a tube of toothpaste containing microbeads may have over 200,000,with similar stories for facial cleansers and exfoliating skin soaps. It is because of their abrasion qualities they have been used, however because they are so small they can pass through treatment plants and be mistaken for food by fish blocking intestines.

[edit] Plastic pellets

Plastic pellets, also referred to as nurdles are the basic element of most plastic products. They are small grains of specific plastic, normally less than 5mm in diameter by design, supplied to manufacturers in order to melt and mould into plastic products. Their size means many are transported at a time, and the closely resemble food stuff to land and sea life, causing significant danger.

[edit] Secondary microplastics

Secondary microplastic are particles that result from the breakdown of larger plastic items, such as water bottles, toys, containers. This breakdown is caused by exposure to environmental factors, mainly the sun’s radiation and ocean waves.

[edit] Fragments

Fragments are possibly the largest category of microplastics because they are generated by any number of different plastic items from bags to bottle, boxes to baby toys. When these items are discarded incorrectly they may brake physically and then through other factors such as weathering until they become pieces that are smaller than 5mm and categorised as microplastics.

[edit] Microfibers

Microfibres can make up a large majority of micro plastics, they might be classified as primary or secondary, see above.

[edit] Foam

Styrofoam is used in food containers, coffee cups, and packing material, they chemicals from styrofoams can leach into food and beverages, affecting human health. Reheating food in a styrofoam container increases that exposure. Like fragments, styrofoam breaks down into smaller pieces. Most municipalities do not recycle styrofoam.

[edit] Microplastics construction and health

Indication is that the construction industry is the second largest user of plastic, with 20% of plastic waste coming from the construction sector. In 2019 this was estimated to be around 300MT annual global plastic, of which 50% was single use. With increasing programmes and awareness around single use plastics these figures have dropped however piping and conduit are some of the largest users of polymers in construction and consume 35% of total production.

Some of the main types of plastic used in construction include:

- Acrylic.

- Composites.

- Expanded polystyrene.

- ETFE.

- Polycarbonate.

- Polyethylene.

- Polypropylene.

- Polyvinyl chloride (PVC).

- PTFE.

Apart from the significant environmental risks associated with the breaking down, degrading or misplacing of plastics, some studies suggest further areas of concern.

A research project published in the Journal Environmental International by the Vrije Universiteit Amsterdam in the Netherlands, consisted of testing 22 anonymous blood samples from healthy adults for microplastic particles, finding that 17 out of the 22 human blood samples contained microplastic particles.

The most prominent type of plastic, found in over half the samples, was PET plastic, used in water bottles and food packaging. A third of the samples contained polystyrene, used for packaging products, and a quarter of the samples contained polyethylene, commonly used for plastic carrier bags.

Polyethylene is however also used in plastic plumbing pipes, with polyethylene (PE) and cross-linked polyethylene (PEX) most common. A quarter of the blood samples from the study contained plastic of this kind, which has lead to question marks around some of the plastic being used in construction further

[edit] Related articles on Designing Buildings

Featured articles and news

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this.

Comments

[edit] o make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.