Shell construction technologies

To help develop this article, click 'Edit this article' above. For more information see: Shell roof.

Contents |

[edit] Introduction

Shell design and construction technologies have been developing over time from stone masonry domes to brick, concrete, steel and then timber.

Shells are structures enclosing buildings with smooth continuous surfaces (such as vaults and domes). There are shallow and deep shells. Typically, upper parts develop compression and the lower parts develop tension.

Shells are usually built with increasing thickness from the crown towards the base. This is due to the thrust force that becomes larger towards the base. However, there are internal stresses that are created due to this increase in thickness.

[edit] Masonry shell

The principal components of masonry are the masonry elements and mortar embedment. Masonry elements include naturally available stones, dressed stones from quarries, made-up bricks of sun dried clay and burnt bricks in kilns. Mortar in masonry has developed from primitive mud, natural bitumen to a mixture of lime and sand and cement mortar.

Different structural and architectural forms have been developed from these simple building materials. The combinations were used to bring about a variety of geometric forms and patterns.

From a structural point of view masonry is a homogenous material. The strength of the masonry is limited by its weakest joints. Its load-carrying capacity largely depends on the mortar strength. The allowed stresses in masonry are categorised into compressive axial, compressive flexural, tensile flexural and shear.

[edit] Concrete shell

Modern thin concrete shells derive from the ancestry Roman vaults. Concrete has some advantages compared to masonry shells. Concrete is a manufactured material that acts well in large scale works. It can bear compressive and shear forces many times greater than brick and stone masonry. Concrete finds applications in thinner and larger structures. The smoothness and homogeneity of concrete make it a monolithic material. Concrete can carry tension, compression, shear, bending, and torsion as compared to brick or stone masonry.

The development of cement, aggregate and reinforced concrete has made possible the construction of thin shells.

[edit] Barrel shells

Barrel shells are one-way arched 'slabs' spanning between two parallel longitudinal supports. There are long barrels and short barrels. Long barrels behave like a beam, while for short barrel shells the top surfaces act like a series of adjacent arches.

[edit] Conoidal shells

Conoidal refers to a geometric shell formed by rotating a parabola, ellipse or hyperbola about one axis. Conoids consist of two directrix and two straight line generatrices.

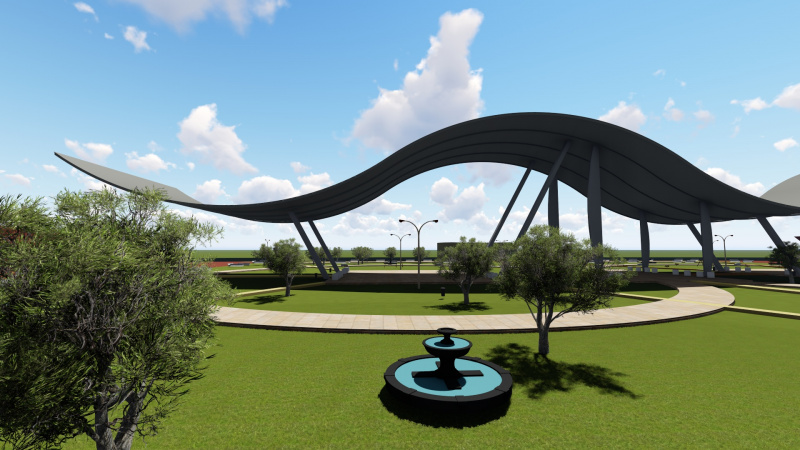

[edit] Cantilevered shells

These are shells that project outward from key points of support. Cantilevered thin shell structures create a sense of an illusion of floating. Just like a cantilevered beam, a cross-section of thin cantilevered shell displays zones with compression and tensile stresses which are transferred to supports by reinforcements and concrete masses.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.