Shell construction technologies

To help develop this article, click 'Edit this article' above. For more information see: Shell roof.

Contents |

[edit] Introduction

Shell design and construction technologies have been developing over time from stone masonry domes to brick, concrete, steel and then timber.

Shells are structures enclosing buildings with smooth continuous surfaces (such as vaults and domes). There are shallow and deep shells. Typically, upper parts develop compression and the lower parts develop tension.

Shells are usually built with increasing thickness from the crown towards the base. This is due to the thrust force that becomes larger towards the base. However, there are internal stresses that are created due to this increase in thickness.

[edit] Masonry shell

The principal components of masonry are the masonry elements and mortar embedment. Masonry elements include naturally available stones, dressed stones from quarries, made-up bricks of sun dried clay and burnt bricks in kilns. Mortar in masonry has developed from primitive mud, natural bitumen to a mixture of lime and sand and cement mortar.

Different structural and architectural forms have been developed from these simple building materials. The combinations were used to bring about a variety of geometric forms and patterns.

From a structural point of view masonry is a homogenous material. The strength of the masonry is limited by its weakest joints. Its load-carrying capacity largely depends on the mortar strength. The allowed stresses in masonry are categorised into compressive axial, compressive flexural, tensile flexural and shear.

[edit] Concrete shell

Modern thin concrete shells derive from the ancestry Roman vaults. Concrete has some advantages compared to masonry shells. Concrete is a manufactured material that acts well in large scale works. It can bear compressive and shear forces many times greater than brick and stone masonry. Concrete finds applications in thinner and larger structures. The smoothness and homogeneity of concrete make it a monolithic material. Concrete can carry tension, compression, shear, bending, and torsion as compared to brick or stone masonry.

The development of cement, aggregate and reinforced concrete has made possible the construction of thin shells.

[edit] Barrel shells

Barrel shells are one-way arched 'slabs' spanning between two parallel longitudinal supports. There are long barrels and short barrels. Long barrels behave like a beam, while for short barrel shells the top surfaces act like a series of adjacent arches.

[edit] Conoidal shells

Conoidal refers to a geometric shell formed by rotating a parabola, ellipse or hyperbola about one axis. Conoids consist of two directrix and two straight line generatrices.

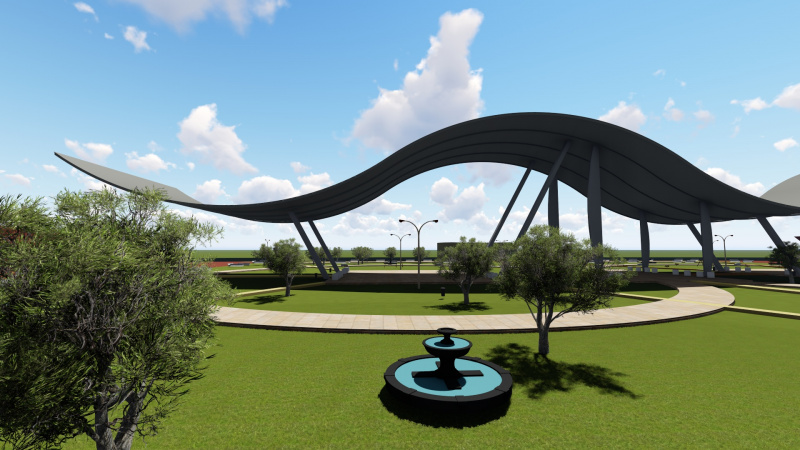

[edit] Cantilevered shells

These are shells that project outward from key points of support. Cantilevered thin shell structures create a sense of an illusion of floating. Just like a cantilevered beam, a cross-section of thin cantilevered shell displays zones with compression and tensile stresses which are transferred to supports by reinforcements and concrete masses.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.