Dowel laminated timber DLT

Dowel Laminated Timber (DLT) is also know as brettstapel, literally meaning board stack in German. it is a technique of constructing large-scale solid timber panels for use as structural or non-structural elements, utilising smaller untreated sawn timber sections, which are mechanically fixed together with timber dowels.

In a similar way to traditional green oak frame the dowels are seasoned or dried, whilst the main body of timbers are not, so the have a higher moisture content, the dowels soak the moisture from their wetter surroundings and expand ensuring the dowels connection is strong and tight. In oak framing structure the dowels tend to also be made from oak, in DLT they may be made from beech or any other suitably dried hardwood, in both cases the structure and dowels dry over time creating stable established connections.

DLT is said to have been originally conceived by the German engineer Julius Natterer in around the 1970s (hence the reason it is still often referred to as brettstaple). At this time the technique consisted of low grade posts of sawn timber laid side by side, continuously nailed together to create solid structural elements, which then evolved to include glues for increased strength and wider spans. Apart from issues around end of life scenarios, the randomly placed nails also caused problems for modifying or cutting any elements.

In 1999 a German company developed a dowelled wood system (Dübelholz) replacing the nails, this overcame the issues of modification and end-of life because the system became a single material solution. However contraction and expansion from variations in temperature or moisture over time, could potentially cause separation along the dowel axi, compromising strength leading to reintroduction of glue or nails.

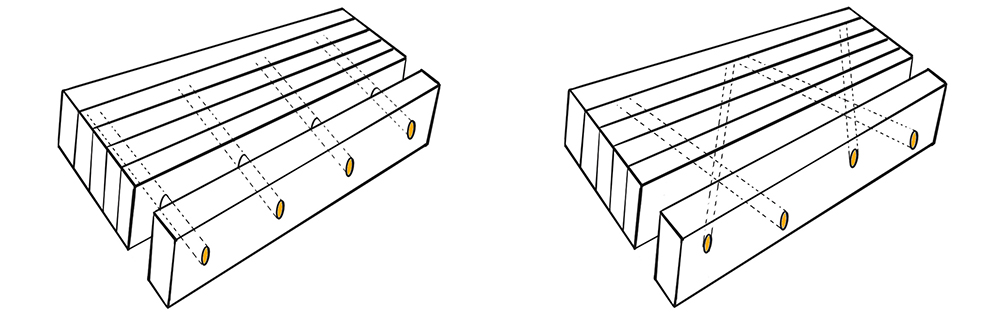

2001 An Austrian company developed a system of inserting timber dowels at angles through the posts in ‘V’ and ‘W’ formations to solve the issue, it virtually eliminated the potential for movement gaps retaining a 100% timber product. Other manufacturers have different means of dealing with the issue, including driving dowels through rotating layers of boards, though this is perhaps the most innovative.

Today many different companies manufacture Brettstapel in Austria, Germany, Switzerland and Norway. The most common form of Brettstapel is the perpendicular dowel with the majority of systems not utilising any glue. DLT utilizes locally sourced material and does not include adhesives it can be considered a natural low carbon value engineered product.

[edit] Related articles on Designing Buildings

- Carpentry.

- Compressive strength of timber lattice columns for low-rise construction.

- Cross laminated timber.

- Nail Laminated timber.

- Engineered bamboo.

- Engineered wood products.

- Facts about forestry.

- Glulam.

- Janka hardness rating scale.

- Laminated veneer lumber LVL.

- Modified wood.

- Nails - a brief history.

- Plywood.

- Predicting service life of timber structures.

- Sustainable timber.

- Testing timber.

- The differences between hardwood and softwood.

- The use of timber in construction.

- Timber frame.

- Timber vs wood.

- Types of timber.

- Types of timber species.

- Whole life carbon assessment of timber.

- Wood around the world.

[edit] External Links

Featured articles and news

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.

UK Infrastructure: A 10 Year Strategy. In brief with reactions

With the National Infrastructure and Service Transformation Authority (NISTA).

Comments

[edit] To make a comment about this article, or to suggest changes, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.