Planning the commissioning of buildings

The best commissioning process is one that is planned from the project’s very inception. Designing in the ability to commission systems properly from the outset can provide huge benefits, especially on cost and performance.

Essentially, good commissioning is the difference between providing a feature that works, and one where its functionality for the end-users has been verified. For example, it’s one thing to include a meter or valve in a design, and another to install it in an easily accessible place. (Even in the exemplar buildings in the Carbon Trust’s LCBP research, installation errors were still found, such as sub-meters installed at toe level.)

Several projects in the LCBP programme had appointed an independent commissioning specialist to oversee the whole process, from design through construction and, vitally, during handover. The specialist in these cases was appointed by the main contractor.

In a parallel initiative, the Commissioning Specialists Association (CSA) is recommending that clients appoint a commissioning verification engineer to monitor the process as the ‘client’s friend’. This sits comfortably with practices followed by the more successful LCBP projects. The common factor in many cases was where a person or organisation was involved continuously throughout the design and construction process, and on into occupation.

While a commissioning manager will usually be appointed by the main contractor, they can be appointed directly by the client. This might be the case where the client is an owner-operator, such as a university, and/or has a vested interest in the commissioning being carried out correctly at the early stages to reduce long-term running costs.

LCBP projects that were run by a knowledgeable, interested client, and where a commissioning consultant had been appointed to oversee the process enjoyed a building with better performance and fewer ongoing defects. Others, where there was no follow through from those involved during the construction, tended to suffer performance penalities. These penalties were usually seen in energy consumption being much higher than the design prediction, and low levels of occupant satisfaction with comfort factors, such as temperature, air quality and noise.

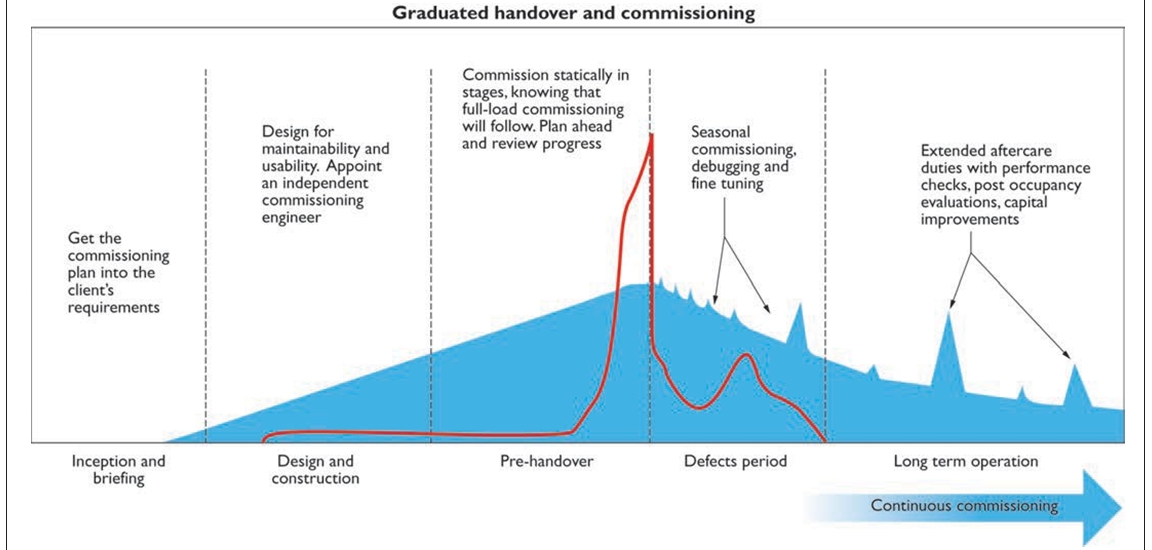

Above: The new professional’s view of commissioning overlain on the old leave-it-to-the- last-minute approach to commissioning. The commissioning plan is started at the early stage of the project, and populated with detail as it becomes available. This approach calls on project professionals to plan early, reality-check as they go along, prepare fully for handover, and follow through after occupation to fine-tune and resolve issues as they emerge.

Above: How not to install an electrical sub-meter: at toe level on the distribution board. This happened on each floor of an office block, studied by the Carbon Trust. It might not have mattered had the BMS been set up to read the meter pulses correctly. It wasn’t. The BMS was found to miss around 60 per cent of the meter pulses. Sadly it’s not unusual.

This article originally appeared in Delta T Magazine May 2011, written by BSRIA’s James Parker. It was posted here by --BSRIA 08:31, 26 November 2014 (UTC).

[edit] Related articles on Designing Buildings Wiki

- At your services - What to expect during commissioning.

- Client commissioning.

- Commissioning.

- Commissioning documents.

- Commissioning notice.

- Commissioning plan.

- Commissioning v testing.

- Corrosion in heating and cooling systems.

- Handover to client.

- Initial commissioning case studies.

- Inspection.

- Migration strategy.

- Practical completion.

- Seasonal and continuous commissioning.

- Soft landings.

- Specialist commissioning manager.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”